High-end renovation project - High-end climate solutions

Waldorf Astoria by Hilton, Amsterdam, the Netherlands

How to combine today’s comfort and engineering with Amsterdam’s history of the 17th century? This is the greatest challenge of the renovation project of the prestigious Waldorf Astoria Hotel in Amsterdam.

Conversion of historical canal houses into a hotel requires a perfectly controllable climate control system. The Waldorf Astoria Hotel in Amsterdam is an extraordinary project. Six historical canal houses were being renovated and combined into a top-class hotel, equipped with state-of-the-art climate solutions.

Amsterdam’s history

The renovation project ‘Waldorf Astoria’ evokes memories of the time of the Dutch East India Company (VOC) in the 1670s. The project’s six grand and impressive houses, which are situated at the Herengracht in Amsterdam, were once residential houses of prominent regents and merchants. The houses were furnished with special facades and landings, the marble hallways received stucco ceilings and rich ornaments.

Fortunately, the architectural characteristics of these canal houses were preserved, important features that Waldorf Astoria wanted to maintain in its latest hotel. Historical elements, combined with state-of-the-art technology regarding comfort and climate control.

The best solutions

During the engineering phase, Cofely collaborated with Danfoss concerning the design. The client’s requirements, i.e. comfort, noise, reliability, sustainability and energy consumption, were all considered in the design phase. The combination of radiators and fan coil units required special attention to fulfill all requirements. Eventually, the chosen solution combines fan coils controlled by Danfoss AB-QM pressure independent balancing and control valves with the very durable Danfoss AME 110NL actuators.

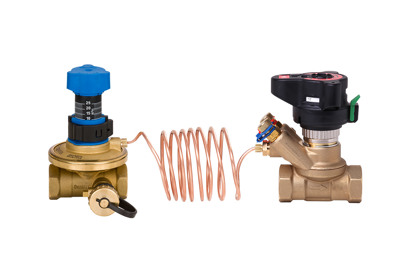

The radiator system is equipped with Danfoss ASV pressure controllers in combination with pre-set radiator valves (RA-N) with ABNM actuators. This ensures the optimum hydraulic balance of the system both under partial and full load. This not only provides additional comfort to the rooms, but also results in the required energy savings. Furthermore, the guests will not be bothered anymore by flow noises in the pipelines.

Extraordinary project

During an interview with Cofely, main project manager Herman Hooning said that only top-class products, so-called A brands, were used for this project. “This is an extraordinary project and quality is our top priority. In addition to that, all suppliers are held responsible for the supplied work. It is assumed that issues are solved without any hassle.”

Cofely is responsible for the main engineering of all mechanical engineering systems. Asked why Danfoss products are implemented, Michel van Soest, planning engineer for Cofely, says that the products are simply very reliable.

New Waldorf Astoria hotel

Among the hotels of the Hilton chain, Waldorf Astoria hotels are the most prestigious.

Most people know the legendary hotel at Park Avenue in New York, but there are 27 similar hotels at the most beautiful spots in the world.

And the latest addition is now this elegant hotel situated along a canal in the heart of Amsterdam. Entering the glamorous lobby with its marble floor, original ornaments and details made of gold leaf, the guests are right in the middle of overwhelming luxury. The hotel has 94 rooms and suites, a spa area with indoor pool and an exercise room. There is a restaurant and a bar, which is situated in an old original MeesPierson bank vault, the previous occupant of the house. Weddings and conferences can also be hosted: the hotel has a ballroom and modern meeting rooms with state-of-the-art digital facilities.

System overview

Fan coil units and air

handling units:

- 214 Danfoss AB-QM (DN10-65)

- 214 Danfoss AME 435QM /

AME110NL

Radiators:

- 8 ASV (DN20-32)

- 400 RA-N and ABNM actuators

"Projects like this must run smoothly from the start. Once the AB-QMs are adjusted, you don’t have to worry about them anymore. They just work and we never have any complaints. Furthermore, it is not really important when or where the AB-QMs are placed. The valves have a pressure independent control feature, which enables a gradual delivery of a project. This saves time and gives a lot of peace of mind."

Erik Woerde, main technician for Cofely

"AB-QM is a reliable product. It is a readily controllable valve. It can be constantly or variably adjusted and this is the reason why our engineering department has chosen this product."

Michel van Soest, planning engineer for Cofely

Related products

-

if (isSmallPicture) {

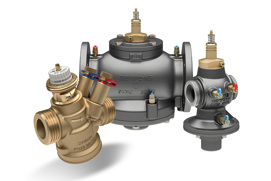

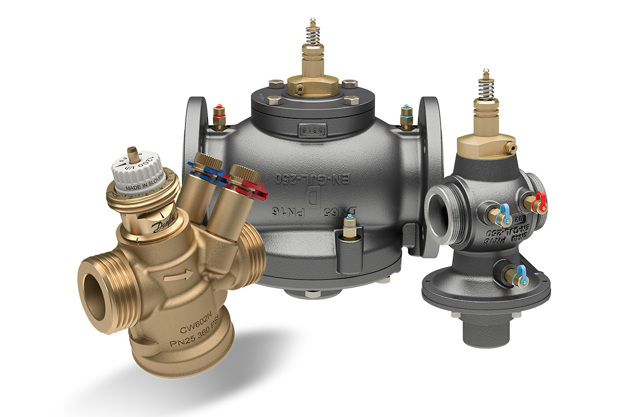

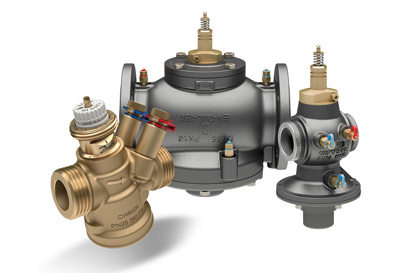

AB-QM Pressure Independent Control Valves (PICV) DN15 - DN250

AB-QM Pressure Independent Control Valves (PICV) DN15 - DN250AB-QM Pressure Independent balancing and Control Valves (PICV) provide both a control functionality and dynamic balancing solution for HVAC heating and cooling systems. PICVs are designed for various types of terminal units, Air Handling Units (AHU), chillers and provide high indoor comfort and energy efficiency in public and commercial buildings.

-

if (isSmallPicture) {

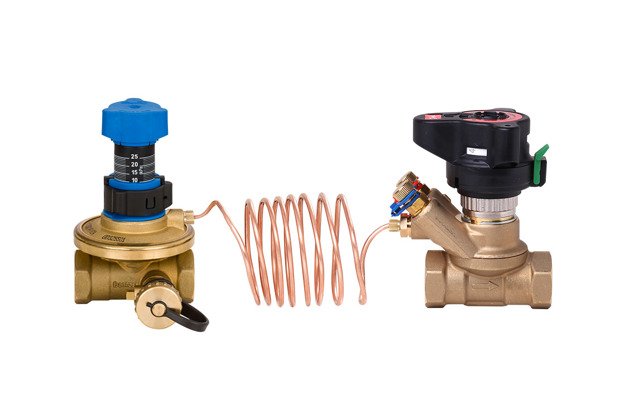

ASV Automatic balancing valves

ASV Automatic balancing valvesASV automatic balancing valves provide a dynamic balancing solution for two-pipe heating or cooling applications. The riser-mounted valves eliminate pressure fluctuations occurring in variable flow systems at partial load conditions. For a proper hydronic balance the valves should be combined with pre-setting valves.