BELGIUM: LuxFly, the operator of Europe’s largest vertical wind tunnel, has chosen AC drives from Danfoss to control the fans that propel air at up to 250 km/h through the 35 m high installation. Unlike most wind tunnels, this one is not used for testing – except perhaps to test people’s taste for excitement – it is used for skydiving! With no special equipment other than a flight suit, helmet, and goggles, LuxFly customers ‘fly’ in the wind tunnel, where they enjoy an experience almost exactly the same as a skydiving jump from a height of 4000 m.

To provide the skydiving experience, the wind tunnel adopts a sophisticated design. It has four vertical intake sections with a fan at the base of each. The incoming air is initially accelerated downward in each of the intake ducts. It is then redirected by diverting vanes so that the flow from all the ducts coincides at the bottom of the wind tunnel proper. Here, additional vanes turn and accelerate the air upwards, so it reaches the speed and volume needed to support the skydivers as they ‘fly’.

The challenge: Keeping people safe with changing air speed

Operating this complex installation efficiently and safely involves numerous challenges. Steve Braff, LuxFly’s CEO, clearly spelt out these challenges:

“Before incorporating Danfoss drives into our operations, our primary challenge was energy efficiency and system reliability. Our vertical wind tunnels consume a significant amount of energy, and maintaining a consistent, smooth airflow is crucial for both safety and customer experience. Additionally, we faced challenges with system downtimes and maintenance costs, which affected our profitability and customer satisfaction.”

“The major challenge was to find a drive solution that could not only handle the complex requirements of a wind tunnel but also operate efficiently to reduce energy costs. The operational stability needed to be impeccable to ensure safety protocols and deliver a consistent and enjoyable flying experience for our customers” Steve Braff adds.

Addressing these challenges required considering the size of the installation – the total load of the wind tunnel can be as high as 1.6 MW – and the need for responsiveness when changes to the air speed in the tunnel are needed.

The solution: Controlling the airflow with VLT® Automation Drive FC 302

Danfoss and LuxFly developed the solution in close conjunction, involving the supply and installation of four VLT® Automation Drive FC 302 drives, each rated at 400 kW and each controlling one of the installation’s main fans. These drives were selected because of their high efficiency and because they offer exceptional dynamic performance, which is essential to provide a fast response to changes in airflow requirements in the wind tunnel.

To ensure smooth installation and commissioning of the drives, and that operational downtime would, in the future, be kept to an absolute minimum, LuxFly opted to use the Danfoss DrivePro® Start-Up and DrivePro® Preventive Maintenance services. These services were augmented with a customized Uptime Response Agreement, which guarantees breakdown response within 8 hours by Drives Service Center based in Belgium – a DrivePro® Service Partner.

DrivePro® Start-Up service ensures that all necessary preparations for drive installation and commissioning are in place so that the work can proceed without interruption. It also includes setting up the drives to match the application and to ensure maximum performance and economy.

DrivePro® Preventive Maintenance includes the development of an agreed maintenance schedule and regular visits to the site by an engineer to perform drive inspections and to carry out basic maintenance tasks. The inspection aims to detect incipient fault conditions that require further attention to prevent them from developing into failures and to ensure that the AC drive continues to achieve its full performance potential.

LuxFly also plans to utilize the Danfoss DrivePro® Remote Monitoring service, which allows Danfoss engineers to collect information from the drives remotely as an aid to identifying and rectifying faults and to support the planning of maintenance.

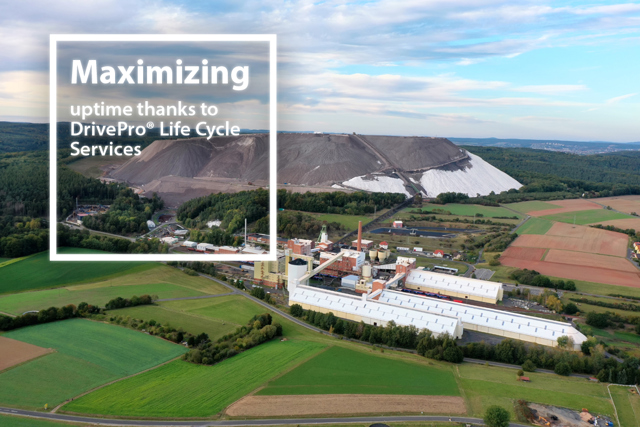

The outcome: Flawless installation and 99,5% operational uptime

Discussing the outcome of this important project, Steve Braff said: “The installation phase went flawlessly for us. We adhered to the planned timeline and experienced no delays or issues. The Danfoss team was incredibly supportive throughout the process, ensuring that the system was set up to meet our specific needs and operational goals.”

After the new drives had been installed and commissioned, the operation of the drive system has been completely problem-free. In the words of Steve Braff, “The Danfoss solution is performing reliably in terms of operational stability, which is a critical factor for the safety and experience. We have maintained a 99.5% operational uptime since implementing the Danfoss drives, which is a testament to their reliability. The system is robust and reliable, and we are exploring ways to better leverage its potential for energy efficiency and remote management.”

Explore the products

-

if (isSmallPicture) {

DrivePro® Preventive Maintenance

DrivePro® Preventive MaintenanceTake the guesswork out of your maintenance plan. With a structured maintenance program tailored to your needs, you can boost operational efficiency and reduce the effects of wear and tear.

-

if (isSmallPicture) {

DrivePro® Start-up

DrivePro® Start-upTake the complexity out of commissioning with DrivePro® Start-up’s full range of health checks and adjustments. Our DrivePro® experts inspect and test your AC drive and motor performance to ensure the best configuration of your AC drives.

-

if (isSmallPicture) {

VLT® AutomationDrive FC 301 / FC 302

VLT® AutomationDrive FC 301 / FC 302The VLT® AutomationDrive FC 301 / FC 302 is designed for variable speed control of all asynchronous motors and permanent magnet motors. It comes in a standard version (FC 301) and an advanced high dynamic version (FC 302) with additional functionalities.