A complete product portfolio, including active filters for harmonic mitigation, opened the doors to a large scale, eco-friendly Chinese desalination plant.

The Cafoeidian Desalination plant is envisioned as the model for ‘green desalination’ in China. Only a 2.5 hours drive from Beijing, the Caofeidian industrial zone takes up 310 km2 of reclaimed land, and is home to a wide range of industries.

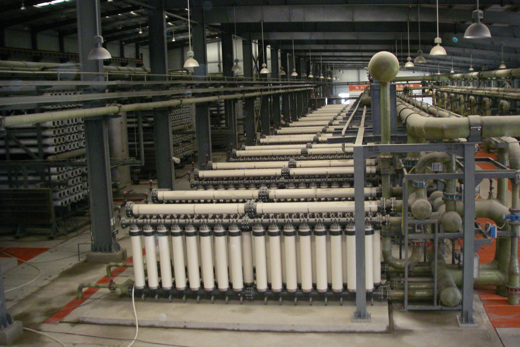

The zone’s desalination plant, which opened in September 2012 after three years of construction, is designed for a capacity of 50,000 m3 of water per day. Clean drinking water is transported to households, while the concentrated brine, a by-product of the reverse osmosis process, is sent away for further industrial treatment and utilization.

1.1 MW drives used for reverse osmosis

In order to secure high efficiency and the necessary pressure required in order for the reverse osmosis process to yield the best results, Danfoss VLT® AQUA Drives are specified for all the pumps in the plant. The drives are supported by VLT® Advanced Active Filters that keep harmonics at specified, low levels while offering much higher energy efficiency than using e.g. active front end technology.

The plant is split into 5 trains of 10,000 m3/d to obtain a high uptime for the total facility. A key task for the 1.1 MW large AQUA drives, which control the high pressure pumps on each train, is to secure the correct flow velocity across the membranes. The velocity must be independent of membrane fouling, temperature and salt concentration to secure the maximum output from the facility and long intervals between membrane cleaning.

“The Danfoss products provided us with a stable and reliable solution for controlling high-pressure pump, UF feed pump, lift pump and backwashing pump. The Chinese language operation interface, 3C3-level anti-corrosion coating and built-in DC reactor helped us resolve tricky application issues during the project.” says Mr. Cheng Wensong, General engineer of electrical Design Department of Hangzhou Xidoumen Water Treatment Company.

The total power of the drives amounts to 11.4 MW, covering a total number of 57 VFDs. Power sizes range from 0.37 kW to 1.1 MW divided among five groups, averaging at 1.8 MW in each group. The drives control all the pump applications in the plant.

“After operation, Danfoss drives’ unique water pump control performance has brought us a lot of functions previously completed by other equipment (Including slow closing check valve function, horizontal pipe fill mode, auto energy curve record function etc.). The convenient Chinese graphical user interface was extremely helpful for commissioning and maintenance.” says Mr. Cheng Wensong.

Clean power supply with active harmonic filters

Due to the large number of variable speed drives used in the plant, the plant’s owners were concerned about harmonic disturbances. If left unmitigated, harmonics lower overall efficiency and in the worst cases cause malfunctions.

Although Danfoss VLT drives are all supplied with built-in DC coils that remedy the worst effects of harmonics, the desalination plant’s ambition was to reduce harmonics to maximum 5%. This would enable them to reduce the risk of breakdown and uphold high efficiency in the process, even in part load conditions.

After reviewing analyses and calculations the system designer and plant owners acknowledged that VLT® Advanced Active Filters AAF 005 were the optimal solution.

AAF 5 filters actively mitigate harmonic distortion caused by non-linear loads by generating and injecting counter-phased harmonic and reactive currents. As a result network capacity is increased, the risk of breakdowns is reduced, and the lifetime of the equipment increased.

“By using the Danfoss AAF series of products, the total voltage distortion rate of our low-voltage power grid has a THDv less than 5%.

Our factory’s overall low voltage power now complies with Chinese GB/T14549-93 harmonic governance standards, which increases the load capacity of the drives, and eliminates problems related to harmonic waves.” says Mr. Cheng Wensong.

Save more energy with active filters

Seen from a cost perspective, active filtration saves additional energy compared to more traditional harmonic filter solutions. It also reduces cable losses, enabling owners to utilize their transformers efficiently without the risk of harming their equipment. Due to the fact that the filters use the same platform as the VFDs, they were easy to integrate and set up.

Before turning on the filters on the total harmonic distortion, THvD was 6.2%. With the filters in operation this figure dropped to 4.7%, well inside the required limits, meeting IEC61000-2-4 Class 1 standards.

“Based on the above points, we believe Danfoss FC202 series drives and advanced active filters are the best products we have used in the water treatment industry. The unique software setting features, timely and thoughtful after-sales service, good product quality and perfect harmonic suppression function all made a deep impression on us.” says Mr. Cheng Wensong.

Get more information

Read more about VLT® AQUA Drive FC 202

Read more about Advanced Active Filters

Read more about Water and wastewater