MEXICO: Faced with the challenge of pumping stagnant water from depths of more than 400 meters, the Cerro Los Gatos mine opted for medium-voltage variable speed pump control using the VACON® 1000 drive from Danfoss. Drives were delivered and installed in the record time of 14 weeks from factory acceptance test.

Discover how Los Gatos mine got VACON® 1000 medium-voltage drives up and running in a record 14 weeks

Robust reliability for 24/7 operation

The Cerro Los Gatos Mine, the Esther Deposit and the Amapola Deposit are three silver-lead-zinc sites forming part of the fourteen mineralized zones of the Los Gatos District, the center of the Mexican silver belt.

The Cerro Los Gatos Mine is the first commercially successful mine in the region. Concentrated material is sold in Mexico, to foundry facilities in Japan, and to other locations through intermediaries. The annual production of the mine is about 9.2 million ounces of silver equivalent per year through the mine in stock. Cerro Los Gatos mine has one of the best total maintenance cost profiles (AISC) in the silver industry.

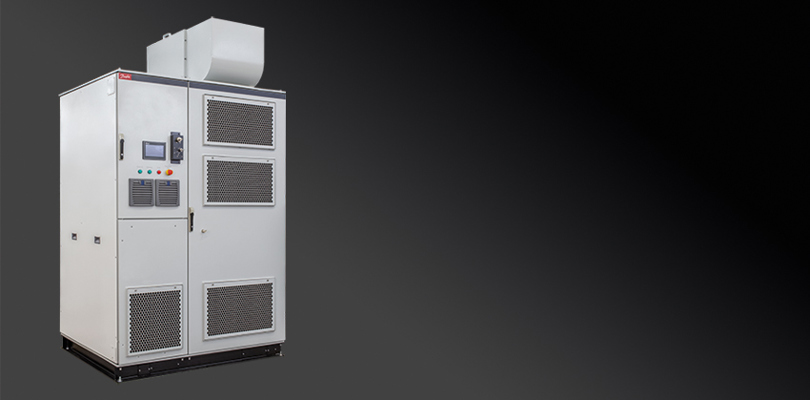

The mining industry operates 24/7, and this specific mine site includes several vertical shafts, which are connected, forming a network of galleries below the surface of the basin, where flooding naturally forms a large underground reservoir. For the Cerro Los Gatos mine to maintain excavation and production, it is necessary to pump out the underground water. With stagnant water at more than 400 meters deep, the Mine Cerro Los Gatos decided to specify two air-cooled VACON® 1000 standalone 128 A / 4160 V medium voltage drives..

VACON® 1000

VACON® 1000 is a general-purpose drive suitable for a wide range of medium voltage applications. It is easy to integrate into the main control systems and adapts quickly to the specific needs of each situation. This MV drive offers high environmental resistance to operate under harsh conditions, with high temperature, dust and humidity inside an electrical room.

The VACON® 1000 drive complies with customer requirements such as compact footprint, low harmonic emission, high energy efficiency, and motor dU/dt requirements. Other relevant characteristics appreciated by the customer are the comprehensive connectivity options, simple installation requirements, and intuitive and safe operation. Availability of local technical support was also an important customer requirement.

Successfully pumping water from 400 m depth

This new generation of drives was installed in Mexico, and the mine became one of the first in the country to implement a solution of this nature to deal with pumping water from great depth.

Installing an effective water pumping system became a multi-phase project. Firstly, the diagnosis was made following on-site visits, then evaluation and selection of solutions commenced. Finally, the solution was installed and commissioned. In each of the phases, Danfoss worked together with the solution integrator and business partner Autronic. Their combined talents formed a multidisciplinary technical and commercial team, which initiated a process of constant communication with users to analyze the various phases of the implementation of the solution.

14 weeks

Thanks to this collaborative approach, manufacturing time was 14 weeks only, a record time for projects of this magnitude. One of the great contributions to achieving this goal was the knowledge and experience of the Mexican technicians. Thanks to their flexibility, availability, and teamwork with the end users, it was possible to complete the project fast.

Danfoss technology was adopted immediately thanks to the fact that the technical doubts were resolved in their entirety: Working together with a multidisciplinary team of engineers, geologists, technicians and operators specializing in mining was one of the key factors for Danfoss, as an OEM supplier cooperated with solution integrator Autronic throughout the process: first providing training to the client and then in the delivery, installation and commissioning of the equipment earlier than predicted.

Generally, these types of solutions are carried out by foreign personnel, so the implementation and service times are extensive. In this case, Danfoss offered immediate response, reducing delivery times due to the availability of local technicians in Mexico.

How fast can we help?

With focus on exceptional customer service, Danfoss completed in two days what other providers normally take 3 or 4 days to achieve. The team had a straightforward way of working, open communication, and total transparency with the customer. Complete alignment with high expectations made it possible to halve the time required for installation supervision, commissioning, and start-up.

Configurable, versatile, reliable MV solution for industrial applications

Related applications

-

if (isSmallPicture) {

Drives for conveyors in mining

Drives for conveyors in miningFlexibility to control the speed of long conveyors can help optimize the complete system, reduce bottlenecks and extend motor lifetime.

-

if (isSmallPicture) {

Drives for cranes in mining and mineral processing

Drives for cranes in mining and mineral processingTo optimize crane and hoist performance, Danfoss offers flexible control strategies combined with energy efficiency, operating within stringent safety requirements.

-

if (isSmallPicture) {

Drives for mine ventilation fans

Drives for mine ventilation fansEnsure reliable and economical fan operation both at the surface and underground, with easy integration into Ventilation on Demand (VoD) systems.

-

if (isSmallPicture) {

Drives for pumps in mining

Drives for pumps in miningReduce substation heat load and reduce air conditioning infrastructure, with air-cooled pump control from Danfoss.

More mining case stories

-

if (isSmallPicture) {

80 kW power savings at Kolomela mine

80 kW power savings at Kolomela mineBack-channel cooling in VLT® AutomationDrives reduces substation heat load enabling use of a smaller air-conditioning system with lower power consumption.

-

if (isSmallPicture) {

30% energy reduction for Yamana Gold

30% energy reduction for Yamana GoldVACON® AC drives improve the operation of underground ventilation and pumping systems and cut energy consumption of many application processes.

-

if (isSmallPicture) {

Optimized production at KWB Coal Mine

Optimized production at KWB Coal Mine90 kW VLT® Drives ease the mechanical stress on the heavy equipment and improve steering when the excavator turns sideways.

-

if (isSmallPicture) {

Minimal energy use at Shanxi Zhongxi Cement

Minimal energy use at Shanxi Zhongxi CementVLT® Drives move a 10.5-km-long conveyor belt. Load sharing between drives transfers energy from downhill segments to the uphill parts.

More medium-voltage case stories

-

if (isSmallPicture) {

MAGDALEN replenishes U.S. beaches with the power of VACON® 3000 medium-voltage drives

MAGDALEN replenishes U.S. beaches with the power of VACON® 3000 medium-voltage drivesUNITED STATES: Somewhere off the coast of New Jersey, the Weeks Marine dredge Magdalen removes thousands of tons of sand off the seafloor and loads it into her hopper. The vessel then navigates to a spot where the shoreline was eroded and discharges the sand there, using slurry pumps powered by medium-voltage drives to reclaim a beach that storms had washed away.

-

if (isSmallPicture) {

Royal IHC Scheldt River pioneers new environmental standards in dredging with flexible MV drives

Royal IHC Scheldt River pioneers new environmental standards in dredging with flexible MV drivesA Danfoss medium-voltage drive solution boosts an inboard dredge pump and increases energy efficiency with a small footprint, minimum weight and low volume - while being robust enough to withstand the harsh marine environment.