AUSTRALIA: In arid outback Australia the bore water pumped up from underground is so hot, it needs cooling before you can drink it. The town of Winton in Queensland has turned this to its advantage by converting heat from the bore water to electricity. A geothermal power station recovers energy during the bore water cooling process then uses it to generate power for the local community.

Generating power from recovered energy

Discover how VACON® drives help the town of Winton to save AUD 100,000 annually

Recovering heat with advanced technology

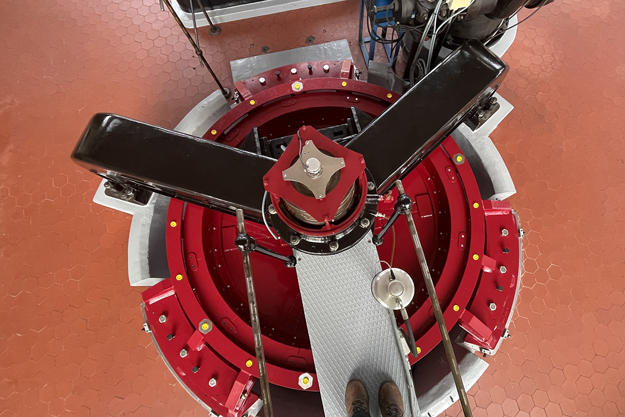

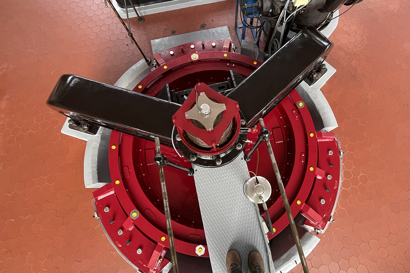

Winton cools the town’s bore water by dumping heat into large cooling ponds. To make use of this heat instead of losing it to the atmosphere, they have installed a geothermal power station, designed and delivered from greenfield site by the green thermal energy company gTET. The installation cools the town’s bore water supply from 86 °C to 53 °C. The power station recovers heat then uses it to generate power using two of gTET’s leading-edge ORC generators.

Exceeding efficiency predictions

The overall performance of the power station has exceeded modelling predictions by up to 10%, and here the efficiency of the drive is a significant contributor - the VACON® drive being an integral component in the power generation system.

The design models for the Winton geothermal plant predicted 100 kW net power generation, for measured inputs of

- bore water at 85.1 °C temperature flowing at 30 liters per second, and

- cooling water at 19 °C temperature, flowing at 128 liters per second

With gross power generation capacity of more than 300 kW, the actual output has proven to be as high as 110 kW.

VACON® drive is integral to ORC generator

The VACON® drive is an integral component in gTET’s ORC generator, which cools borewater and generates power using recovered energy. gTET uses the VACON® drive primarily for its high-speed regenerative capability needed to control the micro turboalternators used in the ORC generators. The VACON® drive was also the most economically viable solution found during the selection process.

The two ORC generators each contain an integrated VACON® drive comprising

- VACON® NXP Grid Converter

- VACON® NXI Inverters

- LCL filter

The site also runs a separate VACON® NXP Grid Converter with micro grid application, connected to 75 kW of battery storage.

Certification opens up new opportunities

Danfoss Australia and Danfoss Drives in Finland regularly supported gTET, solving technical queries whilst navigating the AS4777:2015 certification process.

Certification was received in November 2019 and overcame a significant obstacle for gTET to obtain connection approval for any of its Australian ORC generator installations. Now the certification is in place, it will be smooth sailing for similar projects in the future.

Paul Keen, Managing Director of gTET explains:

“The VACON® drive solution provides the functionality needed to effectively control gTET’s turbines with minimal energy losses. And as such, the integrated drive solution is a critical component in gTET’s ORC generators.”

Annual savings of AUD 100,000

The geothermal power station is the only site of its kind in Australia, and so the unique project has also delivered significant promotional, marketing and tourism opportunities for the town of Winton.

The geothermal power station delivers savings of approximately $100,000 annually, made up of power savings and credits. Furthermore, it also reduces the energy required to cool the town water supply via the cooling ponds.

It’s no wonder that the Winton Council is very pleased and excited by the completed project, and is heavily promoting the site with state and federal governments and the public.

About gTET

A private Australian-owned technology-based business, gTET specializes in developing and implementing thermal energy management solutions for business that are optimized for performance and economics.

gTET’s thermodynamics specialists have experience and capabilities in technologies that include refrigeration, waste heat recovery, ORC power generation, cogen/trigen and heat transfer with product and services across a wide range of clients and industries.

-

if (isSmallPicture) {

VACON® NXP Grid Converter

VACON® NXP Grid ConverterAir- and liquid-cooled drives specifically designed for smart grid, energy storage, green hydrogen, power conversion and marine energy management applications.

Read more about solutions for the energy industry

-

if (isSmallPicture) {

Intelligent power conversion for smart grids

Intelligent power conversion for smart gridsBalancing supply and consumption is a complex task in a distributed smart grid, and this is where Danfoss supports you with certified power conversion solutions, saving you time, cost and effort in testing and certification.

More power generation case studies

-

if (isSmallPicture) {

Unlocking efficiency with a drive retrofit at a Czech hydropower plant

Unlocking efficiency with a drive retrofit at a Czech hydropower plantCZECHIA: When 80-year-old gears were replaced by variable speed control at the Albrechtice hydropower plant, power production increased by 10%.

-

if (isSmallPicture) {

PSW and Danfoss: Flexible onshore power for berthed cruise ships

PSW and Danfoss: Flexible onshore power for berthed cruise shipsNORWAY & SWEDEN: PSW (Power and Automation AS) paired up with Danfoss to create compact OPS solutions in three Nordic harbors: Stockholm, Ålesund and Haugesund/Karmsund.

-

if (isSmallPicture) {

Revolutionizing green hydrogen production with Danfoss Drives

Revolutionizing green hydrogen production with Danfoss DrivesDENMARK: The Everfuel HySynergy facility produces green hydrogen with the help of iC7-Hybrid power converters for efficient, cost-effective electrolysis.

-

if (isSmallPicture) {

World’s first ferry powered by iC7-Marine: Aurora Botnia

World’s first ferry powered by iC7-Marine: Aurora BotniaFINLAND: The Aurora Botnia cargo and passenger ferry is equipped with a hybrid-electric propulsion system, powered by liquid-cooled iC7 drives from Danfoss.

-

if (isSmallPicture) {

Danfoss powers high-capacity SmartGrid energy storage

Danfoss powers high-capacity SmartGrid energy storageNETHERLANDS: Retaining 80% capacity after 8000 cycles, SmartGrid smart battery containers promise 21 years of daily discharge and recharge without performance concerns.

-

if (isSmallPicture) {

VACON® drives electrify passenger ferries in Oslo Fjord

VACON® drives electrify passenger ferries in Oslo FjordNORWAY: Electrification of the Nesodden ferries has reduced CO2 emission in the port of Oslo. VACON® drives and power converters play a key role onboard.