POLAND: The district heating company PEC (Przedsiębiorstwo Energetyki Cieplnej - Gliwice Sp. z o.o.) meets the needs of central heating and hot water throughout the city of Gliwice. PEC Gliwice serves 49,000 residential units, amounting to 62% of the city's apartments, as well as numerous public institutions, industrial or service, and commercial facilities.

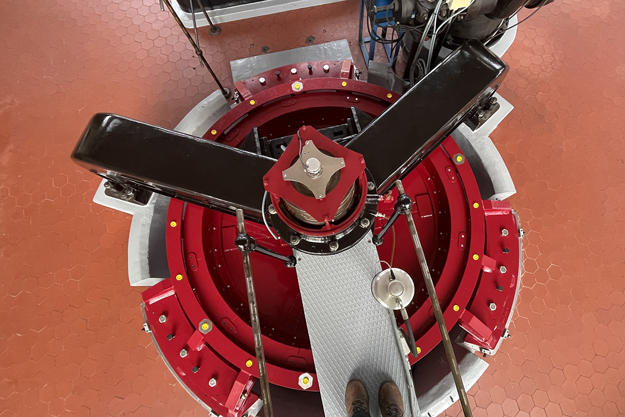

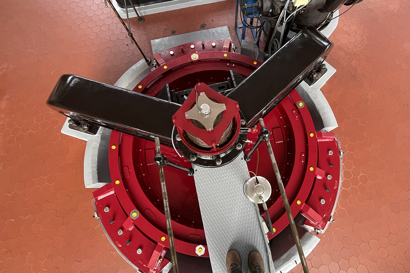

The district heating plant in Gliwice serves an extensive 235-kilometre heating network and comprises advanced technical infrastructure. The heat generation infrastructure consists of two coal-fired boiler plants, two gas-fired boiler plants, a circulating water pumping station, electrostatic precipitators, desulphurisation, and denitrification plants.

To reduce energy consumption and extend the lifetime of machines. PEC installed VACON® drives from Danfoss to control the operation of fans, pumps, and conveyors.

To ensure ongoing correct operation of these drives, Danfoss authorized partner company Neisa performs regular audits.

Challenge: Efficient and secure city heating

The biggest challenge in the operations of PEC Gliwice is to provide safe and environmentally friendly heat for the buildings of Gliwice.

Security of distribution during the heating season is crucial, so it’s vital that the technical infrastructure is reliable. Only regular audits can guarantee failure-free operation of its various components. Moreover, inspections need to be carried out during the summer months, when the demand for PEC Gliwice's services is less than at other times of year.

At the same time, the district heating plant strives to achieve climate neutrality. In addition to investing in renewable energy, it also focuses on reducing the energy consumption of pump motors, fans, and conveyors.

The system heat produced, transmitted, and distributed by PEC Gliwice is used on a daily basis by more than 49,000 Gliwice apartments and many public institutions, industrial plants, educational facilities, as well as service and commercial facilities.

Solution: Risk management with regular inspections

To ensure reliable operation of the drives, Danfoss Drives authorised partner Neisa conducts regular DrivePro® Site Assessment audits. The Tychy-based company performs its inspections in the summer months, considering the needs of both the district heating plant and the residents of the city.

During each inspection, Neisa experts assess the technical condition of the drives to analyse the risks of potential failure. Based on the data collected, specialists carry out repairs.

However, Neisa’s activities do not focus only on current repairs and maintenance. At each inspection, specialists assess whether there may be a risk of technical problems or a decline in performance in the foreseeable future, and on this basis prepare a list of recommendations for replacing equipment or its parts, in the longer term. Neisa’s recommendations are ranked by urgency. In this way, the Gliwice heating plant has time to prepare and assess which repairs specialists should carry out at the next preventive service to help prevent future failures.

The cyclical inspections provide the necessary information about the condition of the infrastructure, which enables PEC Gliwice to prepare a service schedule, as well as planning maintenance of equipment. The service and maintenance activities are also carried out during periods of low demand for heating, to reduce the risk of failure and ensure optimal operation in this crucial period. Audit data is also used to select equipment that needs to be upgraded.

By using correctly programmed variable speed drives, PEC Gliwice reduces the energy consumption of its pumps, conveyors, and fans, bringing them closer to climate neutrality.

Thanks to regular maintenance and repairs, PEC Gliwice has a complete set of necessary infrastructure information. In this way, it can maintain its top performance - for example, by successively upgrading drives. This upgrade includes frequency converters selected for a specific application featuring the right communication protocols or input and output cards.

Outcome: Optimal efficiency and long service life

Regulation by AC drives reduces the energy consumption of electric motors by up to 40%. Neisa's regular DrivePro® Site Assessment audits help ensure that system parameters are always correctly tuned to maintain optimal efficiency.

As well as improving energy efficiency, these regular checks can also improve the lifetime of machines. Constant monitoring and optimization of the drive operating parameters protects machines from possible overloads and short circuits, as well as overheating. It also reduces the inrush current, allowing equipment to start up smoothly.

In summary, the PEC Gliwice district heating plant is powered by VACON® drives that regulate the operation of pump, fan, and conveyor motors. The drives reduce energy consumed by these motors, and also extend their service life by reducing the risk of overloads or current surges. Experts from Neisa, an authorised service partner of Danfoss Drives, ensure that the VACON® drives operate optimally, year in, year out.

With such a policy of preventive maintenance and the knowledge gained about the state of equipment, we can maintain high reliability of equipment operation throughout the heating season.

Explore the products

-

if (isSmallPicture) {

DrivePro® Site Assessment

DrivePro® Site AssessmentOptimize your maintenance strategy with a complete onsite survey and risk analysis of all your AC drives collected in one detailed report. Together with a Danfoss expert, you can build a tailored plan for future maintenance, retrofits, and upgrades based on your exact needs.

-

if (isSmallPicture) {

VACON® 100 INDUSTRIAL

VACON® 100 INDUSTRIALDrive modules and enclosed drives that are easily integrated into all major control systems.

-

if (isSmallPicture) {

VACON® NXC

VACON® NXCAn enclosed drive designed for demanding applications that includes options for Active Front Ends and low harmonic solutions.

Explore DrivePro® Lifecycle Services in action

-

if (isSmallPicture) {

Unlocking efficiency with a drive retrofit at a Czech hydropower plant

Unlocking efficiency with a drive retrofit at a Czech hydropower plantCZECHIA: When 80-year-old gears were replaced by variable speed control at the Albrechtice hydropower plant, power production increased by 10%.

-

if (isSmallPicture) {

Wind tunnel achieves 99.5% uptime with Danfoss DrivePro®

Wind tunnel achieves 99.5% uptime with Danfoss DrivePro®Belgium: Thanks to Danfoss DrivePro® services, LuxFly has achieved 99,5% uptime in Europe’s largest vertical wind tunnel that is used for skydiving.

-

if (isSmallPicture) {

DrivePro® Lifecycle Services secure maximum uptime for Rothes CoRDe

DrivePro® Lifecycle Services secure maximum uptime for Rothes CoRDeSCOTLAND: The Rothes CoRDe plant, a biomass-fired combined heat and power (CHP) plant, ensured maximum uptime thanks to several DrivePro® Lifecycle Services.

-

if (isSmallPicture) {

Refrigeration systems preserve apple quality using VSDs with integrated condition monitoring and DrivePro Remote Monitoring service

Refrigeration systems preserve apple quality using VSDs with integrated condition monitoring and DrivePro Remote Monitoring serviceITALY: At Rivoira Group, VLT® drives with built-in condition-based monitoring help preserve fruit perfectly by ensuring utterly reliable refrigeration.

-

if (isSmallPicture) {

Site assessment secures maximum uptime for K+S

Site assessment secures maximum uptime for K+SGERMANY: Thanks to DrivePro® Life Cycle Services, a K+S potash mine got more uptime and a quick retrofit resulting in a better bottom line.

-

if (isSmallPicture) {

Speedy AC drive retrofit for Linz Strom

Speedy AC drive retrofit for Linz StromAUSTRIA: A Linz Strom power plant needed to replace three ageing AC drives. DrivePro® Life Cycle Services played an essential role in meeting project requirements.