DENMARK: Not only can clean energy help us meet increasing global energy demands, it allows us to achieve critical climate targets. Recent years have brought record growth in the share of renewable energy in the global energy mix, including a renewed interest in green hydrogen, which can be produced with surpluses from renewable wind and solar. Green hydrogen is seen as a promising low-emissions energy source that could – at scale – power heavy-duty industries like land transport and shipping.

Everfuel, a leading Danish green hydrogen provider, took a big step towards their goal of bringing commercial hydrogen to the market with their flagship 20 MW HySynergy facility in Fredericia, Denmark. The ambitious HySynergy project is a collaboration between Everfuel, Crossbridge Energy Fredericia, and several partners, with the aim of pioneering large-scale power-to-X (PtX) technology that draws on existing renewable energy surpluses.

Find out how the Danfoss iC7-Hybrid AC-to-DC grid converter is helping make green hydrogen power, once just a far-off ambition, into an achievable reality.

The challenge: The road to minimizing emissions while maximizing efficiency

With more than 50% of its energy needs supplied by renewable wind and solar power, Denmark is considered a frontrunner in the global race to decarbonize. Against this backdrop, Everfuel believes green hydrogen will play a strong role in more resilient energy systems for the clean energy transition.

However, due to the large amount of energy needed for green hydrogen, it is challenging to provide adequate storage capacity in an efficient way. To establish proof of concept, Everfuel set ambitions to help Crossbridge Energy Fredericia reduce its carbon footprint within existing refinery processes and make a competitive supply of green hydrogen available for Denmark’s transportation sector.

As part of Phase I of the three-phase HySynergy project, Everfuel faced the challenge of constructing the 20 MW PtX facility – the first large-scale electrolyzer in Denmark as well as being among Europe’s largest electrolyzers – and to initiate the delivery of green hydrogen production on a commercial scale. To lay the foundation for their vision, Everfuel required a high-quality and scalable power conversion solution they could rely on for the long term.

The solution: Compact iC7-Hybrid reduces CAPEX

Everfuel selected Danfoss for its renowned expertise in energy efficiency and innovative solutions. The decision was influenced by Danfoss' reputation for providing competitive drive solutions to technical challenges, including superior harmonic footprint, adjustable power factor, and industry-leading liquid-cooling technology.

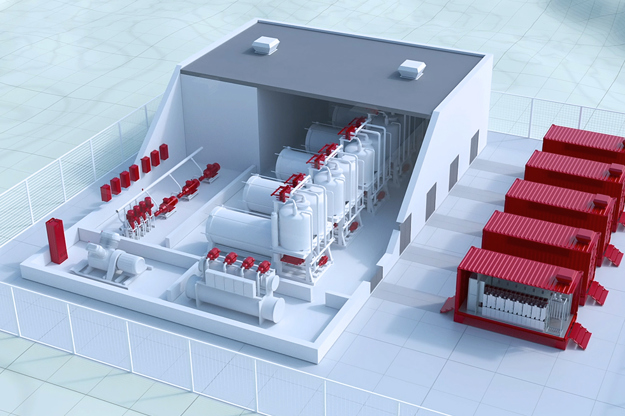

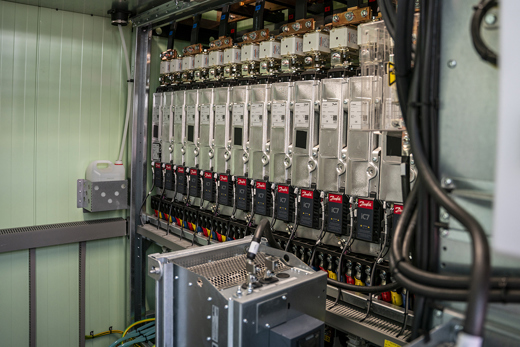

To meet Everfuel’s needs, Danfoss delivered two liquid-cooled AC-to-DC grid converter systems in outdoor duty enclosures. Each grid-compliant system can deliver two 5 MW outputs for the HySynergy project’s Phase I goals. The systems combine the highest power density modules available on the market with thermal management features that cut infrastructure needs and costs significantly. They are particularly electrolyzer friendly with very clean DC voltage and a built-in precharging system. Best of all, the power conversion system is scalable from 20 MW to 1 GW, to accommodate the upcoming expansion phases.

During construction of the Fredericia facility, Everfuel and Danfoss identified additional needs beyond the initial scope and developed the necessary components in close collaboration. Due to their versatility and reliability, Everfuel installed several electric motor drives to support other applications across the facility, including heat pumps, and pumps for water treatment.

The outcome: A pioneer in green hydrogen production

Danfoss iC7-Hybrid power converters play a pivotal role in the HySynergy project. These power converters deliver key technology that enabled Everfuel’s facility to meet its target of test production of the first hydrogen in December 2022. Equipped with high conversion efficiency of 98%, iC7-Hybrid reduces both energy consumption and costs during the conversion of renewable energy sources into hydrogen. Its simplified grid connection also enables heat recovery during hydrogen production, which can be fed back into the grid for district heating in Fredericia. This early result demonstrates the project’s capacity for sector integration.

Everfuel plans for the 20 MW flagship facility to be fully operational in 2024 (Phase I), then to add a further 300 MW of capacity (Phase II). With a view towards its ambitious Phase III goal of achieving 1 GW green hydrogen capacity around the end of the decade, the HySynergy project has laid the groundwork for green hydrogen production at scale. Everfuel is now on track to help decarbonize some of the commercial sector’s most hard-to-abate sectors, including transport and heavy industry, in alignment with Denmark's climate target of 70% CO2 reduction by 2030.

“From my previous time working at Danfoss, I knew they had something interesting in the works, which suited Everfuel's needs quite well. The collaboration on the HySynergy project has been a testament to that. Danfoss Drives has provided state-of-the-art solutions but also demonstrated a partnership in the co-development of new solutions. Their commitment to innovation and excellence resonates with our vision at Everfuel, and it's been a pleasure to see our joint efforts come to fruition. The synergy between our teams has been remarkable, and it's clear that Danfoss Drives is a valuable partner in our journey towards a sustainable future”, explains Uffe Borup, CTO and Co-founder of Everfuel.

Products installed

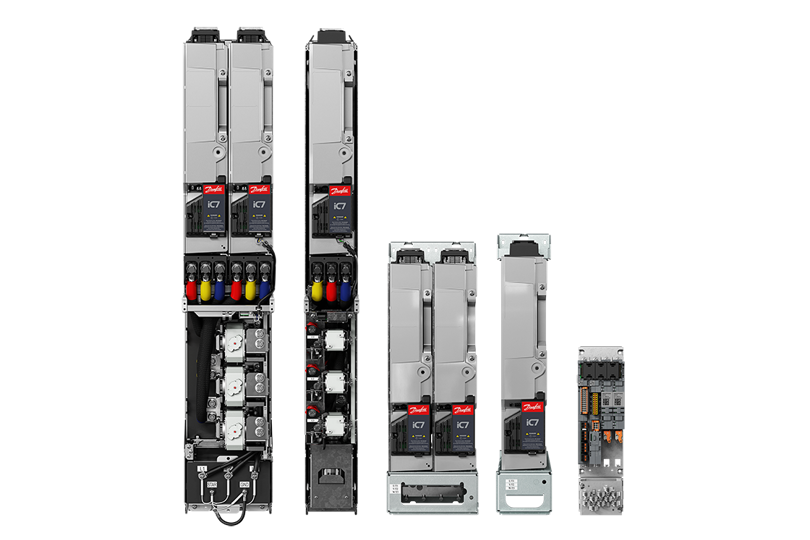

iC7-Hybrid

Open up for intelligent power conversion.

iC7-Hybrid is optimized for all power conversion applications and has an unrivaled power density with new filter technology.

Contact us

To learn more, please contact your nearest Danfoss Drives sales office.