NORWAY: Future of the Fjords represents a new standard of environmentally responsible passenger transport, as the first fully electric carbon fiber vessel in the world. The development of this electric catamaran minimizes environmental impacts in the Norwegian fjords, while maximizing the experience of natural beauty for the passengers – an essential approach for its route between Flåm and Gudvangen in the pristine Nærøyfjord, part of the UNESCO World Heritage park.

Norwegian fjords enter a zero-emission future

In 2018 the Norwegian parliament passed a resolution to make its iconic fjords a zero-emissions zone as soon as possible and by 2026 at the latest. This defines the deadline for vessel operators in the fjords to eliminate pollution emitted by their ships – a deadline which Future of the Fjords has met with eight years to spare.

Optimizing energy efficiency is a key strategy in ensuring the viability of the vessel and reducing its environmental impact. Therefore, Future of the Fjords uses high tech solutions in a range of disciplines to achieve lowest possible energy consumption. Light carbon sandwich laminates for the hull and superstructures ensure approximately half the weight by comparison with conventional materials.

“Quality suppliers such as Danfoss, Westcon and others give us good working conditions and a nearly maintenance-free ship to operate in this area”

- Lars Haugnes, Chief Engineer, Future of the Fjords

Pure performance

The battery-powered propulsion system eliminates NOx and CO2 emissions, and reduces noise and vibrations. The heart of the vessel is the battery pack which drives the two electric motors. When charged, the vessel can run for more than two hours at a speed of 11 knots. No aspect of performance optimization is left to chance. Danfoss solutions are integrated into systems throughout the vessel, working constantly behind the scenes to control, regulate and optimize performance. They ensure reliable operation to reduce maintenance to an absolute minimum.

Lightweight power conversion delivers full thrust

The power system designed by systems integrator Westcon is 2 tons lighter in weight than the next best alternative, which lowers the propulsion power required. This huge benefit for efficiency was only possible due to the freedom of design Danfoss VACON® drives offer, explains Frode Skaar, Business Development Manager at Westcon:

“Thanks to the versatility of Danfoss AC drives which are fully compatible with many alternative technologies, we were able to design both the power system and the shore supply in a very agile manner. Compared to our closest competitor, we could find other types of equipment doing the same job which was 2 tons lighter, required fewer components, and ensured lower power losses, resulting in a better system”

The VACON® drives also enabled Westcon to overcome challenges in heat management of the power conversion systems, resulting from versatile components and a problem-solving process where shipbuilder and owner worked positively and flexibly together throughout.

Fossil-free propulsion

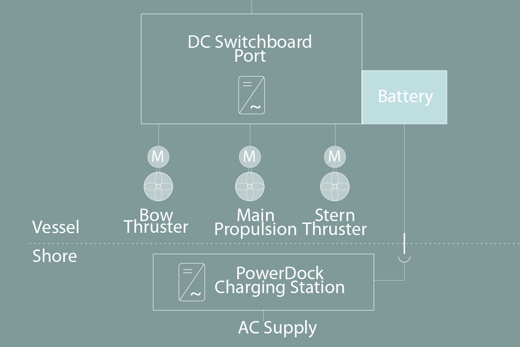

The main propulsion, bow thrusters and stern thrusters are equipped with VACON® drives to control speed and optimize power consumption and maneuverability. These drives also ensure safe and high efficiency power conversion from the battery pack.

World’s first floating power dock

The local mains grid does not have sufficient capacity to charge Future of The Fjords directly. Instead, the vessel recharges its battery at the PowerDock, a floating fiberglass dock with 2.4 MWh charging capacity: 1.2 MWh sourced from a battery pack and 1.2 MWh from the grid. Power Dock charges steadily throughout the day, powered by the local mains grid. Recharging the vessel takes just 20 minutes, during which the dock delivers about 800 kWh of power.

PowerDock also takes care of grey and black water from Future of the Fjords, ensuring no pollution by sewage discharge into the fjords.

Learn about the drives, sensors and switches onboard

-

if (isSmallPicture) {

Pressure transmitters and sensors for marine applications

Pressure transmitters and sensors for marine applicationsMarine approved dedicated pressure transmitters and sensors for marine applications. A wide range of connections and pressure ranges to meet marine requirements.

-

if (isSmallPicture) {

Pressure switches for marine applications

Pressure switches for marine applicationsSwitches to control pressure in marine applications where robustness and space are important factors. Marine approved box and block switches.

-

if (isSmallPicture) {

VACON® NXP DC/DC Converter

VACON® NXP DC/DC ConverterMaximizes the energy yield in hybrid solutions and helps improve performance by bringing energy support close to the consumption.

-

if (isSmallPicture) {

VACON® NXP Grid Converter

VACON® NXP Grid ConverterAir- and liquid-cooled drives specifically designed for smart grid, energy storage, green hydrogen, power conversion and marine energy management applications.

-

if (isSmallPicture) {

VACON® 100 FLOW

VACON® 100 FLOWDedicated functionality that improves flow control and saves energy in industrial pump and fan applications.

Power conversion case studies

-

if (isSmallPicture) {

PSW and Danfoss: Flexible onshore power for berthed cruise ships

PSW and Danfoss: Flexible onshore power for berthed cruise shipsNORWAY & SWEDEN: PSW (Power and Automation AS) paired up with Danfoss to create compact OPS solutions in three Nordic harbors: Stockholm, Ålesund and Haugesund/Karmsund.

-

if (isSmallPicture) {

World’s first ferry powered by iC7-Marine: Aurora Botnia

World’s first ferry powered by iC7-Marine: Aurora BotniaFINLAND: The Aurora Botnia cargo and passenger ferry is equipped with a hybrid-electric propulsion system, powered by liquid-cooled iC7 drives from Danfoss.

-

if (isSmallPicture) {

VACON® drives electrify passenger ferries in Oslo Fjord

VACON® drives electrify passenger ferries in Oslo FjordNORWAY: Electrification of the Nesodden ferries has reduced CO2 emission in the port of Oslo. VACON® drives and power converters play a key role onboard.

-

if (isSmallPicture) {

Decarbonizing the next-generation training ship, Skulebas

Decarbonizing the next-generation training ship, SkulebasNORWAY: The new training vessel at Maløy Fishing School uses less diesel and emits less CO2, while also meeting the rigorous demands of the fishing industry.

-

if (isSmallPicture) {

Where smart ferry charging begins with a smart grid

Where smart ferry charging begins with a smart gridNORWAY: The Hareid-Sulesund ferry operations have reduced CO2 emissions by 7000 tonnes annually with the introduction of electric vessels. In transitioning ferries from diesel to pure electric power, powerful onshore support is essential, in the form of reliable infrastructure for rapid charging capacity and stable grid supply. The systems on board and on shore act as a single system – a sophisticated and competitive system developed by Norwegian Electric Systems (NES) using Danfoss technology.

-

if (isSmallPicture) {

Royal IHC Scheldt River pioneers new environmental standards in dredging with flexible MV drives

Royal IHC Scheldt River pioneers new environmental standards in dredging with flexible MV drivesA Danfoss medium-voltage drive solution boosts an inboard dredge pump and increases energy efficiency with a small footprint, minimum weight and low volume - while being robust enough to withstand the harsh marine environment.