SCOTLAND: The Rothes CoRDe plant is a biomass-fired combined heat and power (CHP) plant located in Rothes, Speyside, Scotland. With an annual fuel input of 115,000 tons of wet draff (distillation residues) from local whisky distilleries and 60,000 tons of uncontaminated wood, the plant generates 7.2 MWe, equivalent to supplying 9,000 homes with electricity.

As part of the turnkey project delivered by Aalborg Energie Technik a/s, the plant relies on 100 VLT® AutomationDrive FC 302 AC units from Danfoss for smooth operation. It is essential that these drives are regularly serviced and maintained to maximize reliability and performance.

The challenge: Learning the status of the AC drives

In their quest to take stock of the current status of the drives on site, the plant’s engineers called upon Danfoss Drives DrivePro® service partner Greenville IDC to complete a DrivePro® Site Assessment.

“We have been working with Rothes CoRDe for a while now and the site assessment was needed for its fleet of drives to help us maintain them at optimum performance,” explained Steven Brown, Regional Manager at Greenville IDC. “We also had to provide an emergency repair for a large 110 kW VLT® AutomationDrive FC 302. We repaired the faulty drive and it’s now a backup spare, which means the plant is covered should there be any more problems in the future”.

The DrivePro® Site Assessment provided an easy way to manage Rothes CoRDe’s installed base of AC drives and to plan for the future. The detailed survey conducted on all AC drives on the shop floor enabled the service team to get a clear picture of the current condition of the AC drives and assess future maintenance needs.

“The site assessment allowed us to advise on spare parts, create a preventive maintenance program and offer breakdown technical support,” said Greenville’s Steven Brown. “Soon after we’d done all of this, a 22 kW AC drive mounted on an industrial fan failed, and we were able to replace the drive the same day, with little fuss or disruption”.

The solution: DrivePro® Retrofit in the midst of the holiday

To complement the onsite audit, Greenville IDC implemented the DrivePro® Retrofit service which allows the replacement of AC drives nearing the end of their useful lives to be scheduled well in advance, thereby ensuring maximum uptime. DrivePro® Retrofit also boosts the overall performance and energy efficiency of AC drive estates by replacing outdated AC drives with the latest technology available from Danfoss Drives and its partners.

To make best use of the benefits provided by DrivePro® Retrofit, the plant scheduled a shutdown for preventive maintenance for four days in July, when most of the employees are on holiday. The shutdown allowed Greenville to extract the drive parameter files, study the alarm history, check that the installation of each drive was correct and in accordance with Danfoss recommendations and also update the drive software to the latest version.

The outcome: Peace of mind for Rothes CoRDe

The improvements brought by Danfoss products and services delivered through its DrivePro® service partner, Greenville IDC, are helping the Rothes CoRDe plant to maintain its leading position in the environmental sector.

The DrivePro® Site Assessment and DrivePro® Retrofit packages are underpinned by unparalleled knowledge, right-on-time spares delivery and exceptional service. But perhaps the most important thing they offer is peace of mind for plant managers with a maintenance strategy and full lifecycle management of their AC drives.

Explore the products

-

if (isSmallPicture) {

DrivePro® Services

DrivePro® ServicesEvery AC drive application is different. DrivePro® Services is a collection of tailor-made products designed around your needs.

From optimized spare part packages to condition-monitoring solutions, customize our products to support your business through the different lifecycle stages of your AC drive.

-

if (isSmallPicture) {

DrivePro® Site Assessment

DrivePro® Site AssessmentOptimize your maintenance strategy with a complete onsite survey and risk analysis of all your AC drives collected in one detailed report. Together with a Danfoss expert, you can build a tailored plan for future maintenance, retrofits, and upgrades based on your exact needs.

-

if (isSmallPicture) {

DrivePro® Retrofit

DrivePro® RetrofitThe DrivePro® Retrofit service offers an onsite audit to plan for the replacement of your AC drive well in advance. Be prepared for the end of your AC drive’s life cycle and ensure minimal unexpected downtime.

-

if (isSmallPicture) {

VLT® AutomationDrive FC 301 / FC 302

VLT® AutomationDrive FC 301 / FC 302The VLT® AutomationDrive FC 301 / FC 302 is designed for variable speed control of all asynchronous motors and permanent magnet motors. It comes in a standard version (FC 301) and an advanced high dynamic version (FC 302) with additional functionalities.

Explore DrivePro® Lifecycle Services in action

-

if (isSmallPicture) {

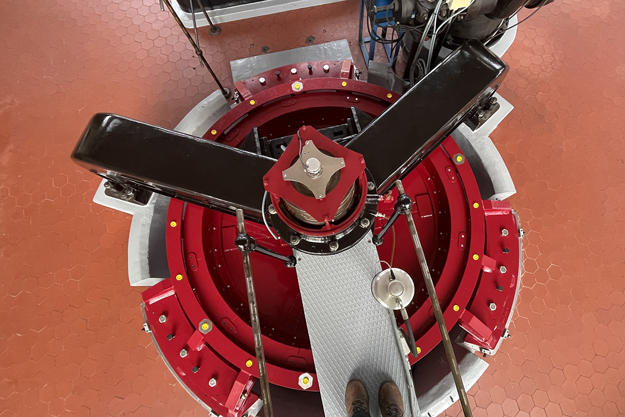

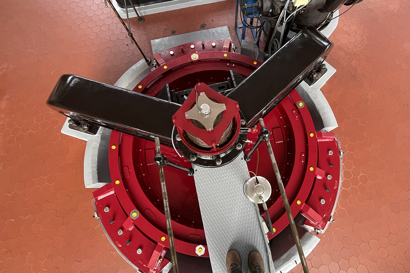

Unlocking efficiency with a drive retrofit at a Czech hydropower plant

Unlocking efficiency with a drive retrofit at a Czech hydropower plantCZECHIA: When 80-year-old gears were replaced by variable speed control at the Albrechtice hydropower plant, power production increased by 10%.

-

if (isSmallPicture) {

Wind tunnel achieves 99.5% uptime with Danfoss DrivePro®

Wind tunnel achieves 99.5% uptime with Danfoss DrivePro®Belgium: Thanks to Danfoss DrivePro® services, LuxFly has achieved 99,5% uptime in Europe’s largest vertical wind tunnel that is used for skydiving.

-

if (isSmallPicture) {

DrivePro® Lifecycle Services secure maximum uptime for Rothes CoRDe

DrivePro® Lifecycle Services secure maximum uptime for Rothes CoRDeSCOTLAND: The Rothes CoRDe plant, a biomass-fired combined heat and power (CHP) plant, ensured maximum uptime thanks to several DrivePro® Lifecycle Services.

-

if (isSmallPicture) {

Refrigeration systems preserve apple quality using VSDs with integrated condition monitoring and DrivePro Remote Monitoring service

Refrigeration systems preserve apple quality using VSDs with integrated condition monitoring and DrivePro Remote Monitoring serviceITALY: At Rivoira Group, VLT® drives with built-in condition-based monitoring help preserve fruit perfectly by ensuring utterly reliable refrigeration.

-

if (isSmallPicture) {

Site assessment secures maximum uptime for K+S

Site assessment secures maximum uptime for K+SGERMANY: Thanks to DrivePro® Life Cycle Services, a K+S potash mine got more uptime and a quick retrofit resulting in a better bottom line.

-

if (isSmallPicture) {

Speedy AC drive retrofit for Linz Strom

Speedy AC drive retrofit for Linz StromAUSTRIA: A Linz Strom power plant needed to replace three ageing AC drives. DrivePro® Life Cycle Services played an essential role in meeting project requirements.