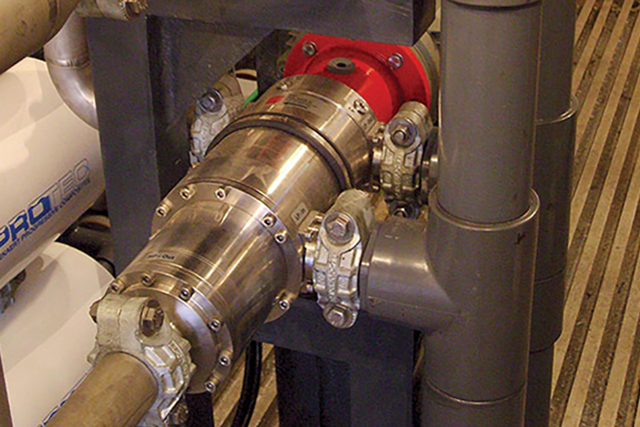

ROCONSERVICES chose a Danfoss APP pump and two iSave energy recovery devices to form the heart of each of its two 180,000 gallon per day seawater RO units in Dockyard, on the west end of Bermuda.

The new RO plant was established in 2009 on a build-own-operate contract, so predictable reliability and market-leading energy efficiency have been vital to ensure project success.

Related products

-

if (isSmallPicture) {

High-pressure pumps for SWRO applications

High-pressure pumps for SWRO applicationsThe range of high-pressure APP pumps is optimized for both landbased, off-shore and marine sea water reverse osmosis applications. Available with or without motor.

-

if (isSmallPicture) {

iSave® energy recovery devices for high-pressure membrane applications

iSave® energy recovery devices for high-pressure membrane applicationsWith a 3-in-1 design that integrates highly effective isobaric pressure exchangers with positive displacement booster pumps and electrical motors, iSave® ERDs deliver big energy savings in small spaces. Covering train sizes from 200-3,000 m3/day