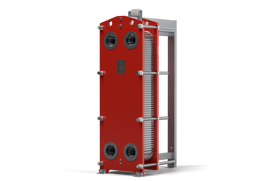

Superior resilience and ability to withstand exceptionally high pressures

Geothermal is emerging as a rapidly expanding sector for Danfoss Heat Exchangers, providing an opportunity for engineering innovation to solutions tailored to geothermal plants, ultimately contributing to a reduction in fossil fuel consumption and CO2. Together with our long-term and trusted partner Geotermia Podhalańska in Poland, we are ready to take geothermal production to the next level.

Heating 1,900 private homes

Geotermia Podhalańska is a prominent player in geothermal energy for district heating utilities. The company emerged as a leading force in the field of geothermal energy to district heating utilities during the 1980s and 1990s.

This period marked the inception of the first buildings integrated into the geothermal heating network, coinciding with the establishment of Geotermia Podhalańska S.A., dedicated to leveraging hot water for commercial purposes.

By 1995, the company had successfully sold 18 TJ (terajoule) of geothermal heat, serving a network encompassing 27 customers.

Heat sales amounted to 533,316 GJ, with 1,563 heat consumers and 1,870 facilities connected to the network. The ordered capacity increased to 78,466 MW and heating up to 83°C. In 2022, 68 new facilities with an ordered capacity of 3,334 MW were connected to the heating network. Today, Geotermia Podhalańska provides heating to almost 1,900 private homes.

The transformative power of geothermal energy shines brightly. Especially, in countries relying on fossil fuels for heating buildings. Its advantage is its independence from weather conditions and renewable nature. We look forward to contributing to your next geothermal project!

Sales Driver Zaur Kuteliya in Danfoss Heat Exchangers highlights:

“Geotermia Podhalańska expressed such satisfaction with our initial heat exchangers that they promptly ordered an additional four units when planning their expansion.

We supplied four S221 Titanium Alloy heat exchangers (AISI 316 TI) with a capacity of 31.2 MW (7.8 MW each). Geothermal applications require titanium plates due to their resistance to chloride.

The solution by Danfoss Heat Exchangers has demonstrated superior resilience to deformation and ability to withstand exceptionally high pressures – exceeding the capabilities of traditional titanium plates. As an additional advantage, they are cheaper than 100% titanium.”

Related products

-

if (isSmallPicture) {

Free Flow plate heat exchangers

Free Flow plate heat exchangersSONDEX® Free Flow plate heat exchangers are the preferred choice for applications that use media with particle-rich contents, fouling tendency, or high viscosity. Each Free Flow heat exchanger is customized to suit your application and media type, with contact-free plate channels for an unimpeded flow and long intervals between cleaning.

-

if (isSmallPicture) {

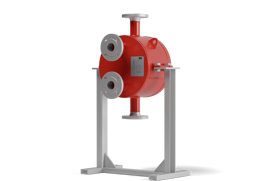

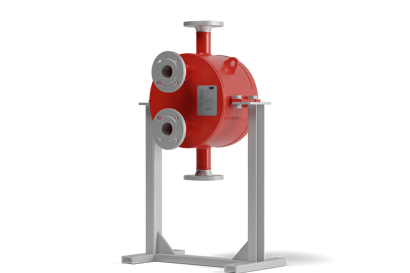

Plate and shell heat exchangers

Plate and shell heat exchangersOur Plate and shell heat exchangers are perfect choices for condensation and steam heating duties. A fully welded plate pack makes the heat exchangers well-suited for handling aggressive media as well as high pressure levels and temperatures. Less space demanding and much lighter in weight, they are good replacements for shell and tube heat exchangers.

-

if (isSmallPicture) {

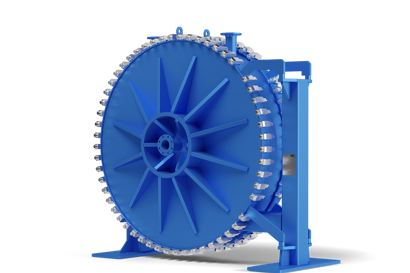

Spiral heat exchangers

Spiral heat exchangersExceptionally well-suited for sludges, slurries, waste water, fouling, liquids with high viscosity, and liquids that contain fibers and solids, our SONDEX® Spiral heat exchangers are the definitive solution for applications that require treatment of challenging fluids. The design allows for a countercurrent flow that makes it possible to achieve very close temperature approaches.

-

if (isSmallPicture) {

Sanitary plate heat exchangers

Sanitary plate heat exchangersSONDEX® sanitary plate heat exchangers are made for applications with strict hygienic requirements and use FDA compliant materials. We care greatly about your end product, and take the necessary steps to ensure the highest output quality. Each solution is designed based on your specifications to provide the perfect conditions for your product.

-

if (isSmallPicture) {

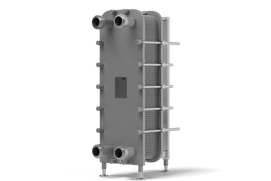

Standard plate heat exchangers

Standard plate heat exchangersSONDEX® standard plate heat exchangers are the ideal choice for a wide range of applications across numerous market segments. We have the largest plate portfolio in the world, and customize each heat exchanger to meet your exact requirements. Innovative technologies and smart design make our traditional plate heat exchangers a stellar investment.