SCM Frigo’s latest project in the Dominican Republic demonstrates that CO₂ refrigeration is not only viable in countries with high ambient temperatures – it is also highly effective in reducing both energy consumption and greenhouse gas emissions. Using Danfoss ejectors, control systems and other key components, the innovative solution cuts a Dominican supermarket’s electricity costs by up to 15%.

Debunking the myth: In fact, CO₂ refrigeration thrives in warm climates and is growing

CO₂ refrigeration systems are gaining traction among food retailers worldwide because the natural refrigerant’s environmental benefits – combined with increased energy efficiency – not only contribute to decarbonization efforts but also to a healthier bottom line. However, their adoption in warmer climates has been slower, despite these areas’ urgent need for energy-efficient solutions. This is paradoxical, because food retailers in warm environments rely heavily on their.

According to Danfoss Food Retail’s segment strategy manager, Gabriele De Bona, the idea that CO₂ refrigeration doesn’t work well in warm climates is based on outdated perceptions. “This was the case many years ago,” he explains, “but innovation has long since made CO₂ a reliable refrigerant in all climates, including high-ambient-temperature environments. Today, with field-proven ejector, parallel compression, and control technologies, we can now engineer CO₂ solutions to be more energy efficient than their chemical alternatives, so CO₂’s environmental advantages are available for more and more use cases, ranging from supermarkets to very large hypermarkets and even much smaller convenience stores.”

SCM Frigo’s latest project in the Dominican Republic for Almacenes Unidos is just the latest in a long line of examples that debunks this myth, and clearly demonstrates the suitability of CO₂ refrigeration in high-ambient-temperature environments.

About the Unidos Punta Cana supermarket

- Location: Punta Cana, Dominican Republic

- Owner: Almacenes Unidos

- Store size: 2180 m2

- Refrigeration cabinets and cold rooms: 9 LT cabinets, 4 LT cold rooms, 25 NT cabinets, 8 NT cold rooms

- Contractor: Frigga Cooling Experts

The Danfoss components specified for the Unidos Punta Cana supermarket’s CO₂ refrigeration system

- AK-CC55 on cabinets and cold rooms

- AK-SM 850A as system manager

- AK-PC 782B in the refrigeration compressors packs

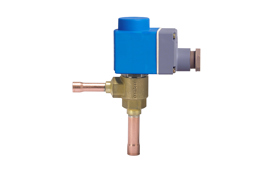

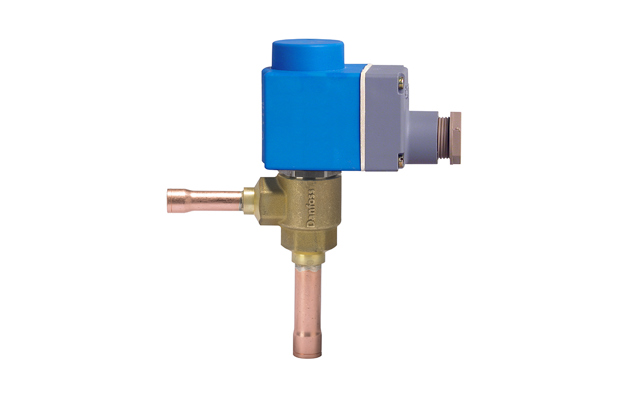

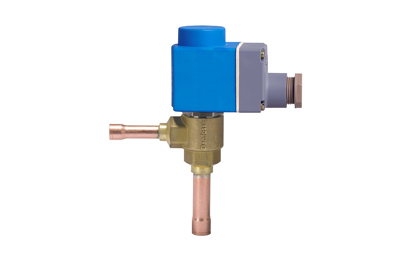

- AKV 10P valves on all the evaporators

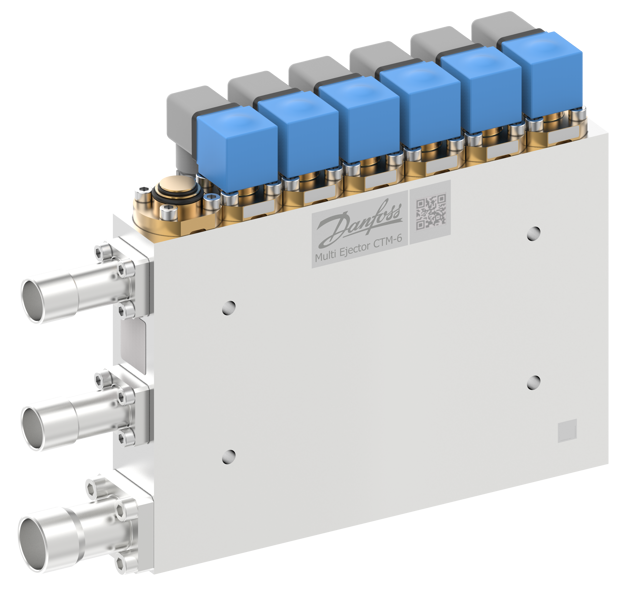

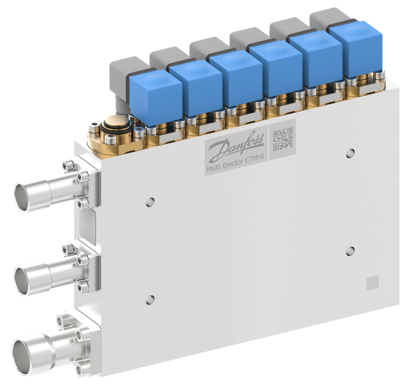

- Multi Ejector - Low Pressure

The Dominican Republic’s first CO₂ refrigeration system at this scale – but not the last

When Almacenes Unidos began planning its first supermarket in the fast-growing region of Punta Cana, the incentives for CO₂ refrigeration were clear. In addition to lowering OPEX, the company also wanted to reduce its greenhouse gas (GHG) emissions. This was in line with the Dominican Republic’s National Cooling Strategy, an initiative that promotes the transition to low-GWP (global warming potential) refrigerants.

“Just like many other major food retailers, Almacenes Unidos has an obvious interest in saving costs and reducing GHG emissions,” says Mirko Bernabei, SCM Frigo’s technical director. “As we know from many previous projects, CO₂ refrigeration delivers on both counts. After the retailer became aware of the positive role that CO₂ refrigeration could play in a hot climate like the Dominican Republic, even at a scale never before seen in that country, their decision was simple. We have experienced the same thing many times before. Once a customer installs a CO₂ system in one store, there is no going back to the old refrigerant alternatives. The financial and environmental advantages are just too compelling.”

Danfoss technology is at the heart of the energy-efficient refrigeration system

According to Bernabei, it is no coincidence that SCM Frigo based its CO₂ solution for the Dominican supermarket on Danfoss technology.

“With Danfoss ejectors, transcritical CO₂ refrigeration can be energy efficient in any climate,” he explains. “By lifting the CO₂ pressure before it reaches the compressor, they reduce the compressor workload to save energy. As a rule of thumb, every degree Celsius of lift corresponds to about 2.5% in energy savings, so reliable ejector technology, integrated with other solutions, is essential to delivering on the potential of CO₂ in warm climates.”

In addition to Danfoss CTM multi ejectors, SCM Frigo engineers also specified Danfoss system managers, valves, and controllers.

“We have partnered with Danfoss on many R&D projects through the years to improve the energy efficiency and reliability of CO₂ refrigeration systems,” says Bernabei, “so we know their integrated solutions well. And we know that Danfoss continues to innovate, with ongoing development of new technologies such as liquid ejectors, which promise even greater efficiency gains in the future.”

Energy-saving results that go right to the bottom line

After more than eight months of operation, the energy efficiency of SCM Frigo’s CO₂ refrigeration system for the Unidos Punta Cana store is clear.

“As expected, Danfoss technology helps us deliver an average lift of 4°C with peaks up to 6.5°C. This energy efficiency boost of 12-15% is a significant CoP improvement that saves money and GHG emissions for Almacenes Unidos every day, year-round.”

Bernabei reports that training and remote monitoring are also important parts of their success. “Refrigeration technology is moving very fast these days,” he explains. “This has huge advantages for energy efficiency and reliability, but it also means that companies need to innovate, and to learn and work together in new ways to keep up. In the old days, we had to send technicians around the world to make adjustments with screwdrivers. Now, we can do many things remotely, and Danfoss technology is also critical here. We look forward to working with them on further innovations in CO₂ refrigeration.”

"As expected, Danfoss technology helps us deliver an average lift of 4°C with peaks up to 6.5°C. This energy efficiency boost of 12-15% is a significant CoP improvement that saves money and GHG emissions for Almacenes Unidos every day, year-round."

The graph above demonstrates the 5-degree Kelvin difference (average value) between the saturated temperature in the MT compressors’ suction line and the evaporator’s exit temperature. The screenshot from Danfoss’s System Manager AK-SM 850 captures the Unidos Punta Cana store’s liquid ejector performance over a typical two-hour period.

About SCM Frigo

SCM Frigo is a global leader in the design and manufacture of CO₂ refrigeration systems. With their innovative approach and focus on energy efficiency and reduced greenhouse gas emissions, SCM Frigo’s product range includes advanced refrigeration systems tailored primarily for the food retail and industrial sectors. Their commitment to quality, customer service, knowledge sharing, and training have made them a trusted partner for businesses worldwide seeking reliable and eco-friendly refrigeration solutions.

SCM Frigo is a subsidiary of Beijer Ref. For more information, see www.scmfrigo.com

Related products

-

if (isSmallPicture) {

Multi Ejector Solution™

Multi Ejector Solution™The Danfoss Multi Ejector Solution™ ensures that transcritical CO₂ applications for retailers become energy efficient in any climate.

-

if (isSmallPicture) {

AKVP – electric expansion valve for food retail applications

AKVP – electric expansion valve for food retail applicationsThe new and improved AKVP Electric Expansion Valve with future-proof technology takes simplicity and safety to the next level. Together with the intelligent Danfoss ADAP-KOOL® controllers, you get the market’s most energy saving solution.

-

if (isSmallPicture) {

System managers

System managersThe system manager is the key component of the intelligent Danfoss ADAP-KOOL® refrigeration system for food retail.

-

if (isSmallPicture) {

Evaporator and room control

Evaporator and room controlDanfoss offers a range of evaporator controls with thermostatic expansion valves or with electric expansion valves.

-

if (isSmallPicture) {

Pack controllers

Pack controllersDanfoss offers a range of compressor and condenser capacity controls for use in food retail, in compact systems as well as in large power packs.