Ananda Foods, Bhimavaram, Andhra Pradesh

Ananda Foods plays a significant role in the fisheries business, contributing to its growth and success. Based out of the state of Andhra Pradesh in India, the company specializes in shrimp hatchery, farming, feed mills, processing, and export.

Danfoss has been working closely with them on different projects for over a decade, offering future-ready solutions that help them enhance their overall productivity, prevent food contamination by maintaining the perfect indoor climate, and improve energy efficiency.

Ananda recently approached us with their plans. They are looking to renovate and automate an existing shrimp processing plant with a cold store. Additionally, they have proposed an investment in anew hatchery. Together, the companies developed a solution – based on Danfoss’ latest industrial refrigeration, electrical floor heating, and Turbocor® solutions – that would offer Ananda the lowest possible total cost of ownership.

The challenge

Making the most of fuel and space, while simplifying maintenance

- Ananda Foods had four main objectives. They wanted to save more plant space, reduce fuel costs, increase efficiency, and simplify maintenance.

- Freezer defrosting was a particular focus area. The company wanted to design a solution that was faster, safer, and more efficient than traditional water defrosting solutions. The Ananda team was also interested in how installing intelligent solutions could help them meet their industrial refrigeration requirements.

- They were also looking for ways to improve floor temperature control.They wanted to protect their storefloors from damage due to moisture migration and improve their naturalventilation systems. And finally, they wanted a more robust and efficient oil-free solution that would help avoid production losses.

- The purpose of the Turbocor® chiller is to constantly maintain the water temperature within the shrimp tank at 22-24°C. The water in the shrimp tank is replaced every 4 hours. The Turbocor® chiller utilizes oil-free technology, which has replaced scroll technology, resulting in improved efficiency and operational cost savings due to extended service intervals (Turbocor® offers service intervals of 5 & 10 years)

The Solution

-

if (isSmallPicture) {

Turbocor®

Turbocor®Danfoss is the leading manufacturer of oil-free compressors and is the pioneer of the Danfoss Turbocor® compressor - the world’s first oil-free magnetic bearing compressor for the HVAC industry.

-

if (isSmallPicture) {

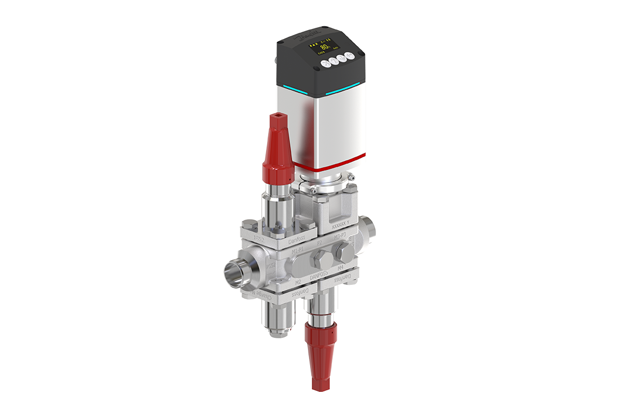

ICF Flexline™ valve station

ICF Flexline™ valve stationUnmatched freedom is the keyword of ICF Flexline™ valve stations. As part of the Flexline™ platform, these valve stations are based on a unique modular concept.

-

if (isSmallPicture) {

IPS 8: Intelligent purging system for industrial refrigeration

IPS 8: Intelligent purging system for industrial refrigerationWith its compact design and automatic purging functionality, the Danfoss intelligent purger system helps improve the operational safety, efficiency and cost-effectiveness of industrial refrigeration systems.

-

if (isSmallPicture) {

Gas detection for industrial refrigeration

Gas detection for industrial refrigerationThe next generation of gas detectors are specifically designed for industrial refrigeration. These gas detectors are built on a digital platform, providing multiple communication and integration options. By leveraging this advanced technology, we offer improved operational reliability, easy calibration, and maintenance efficiency. Our gas detectors are not only cost-effective but also ensure regulatory compliance, enhancing the safety and reliability of the gas monitors in your industrial refrigeration systems.

-

if (isSmallPicture) {

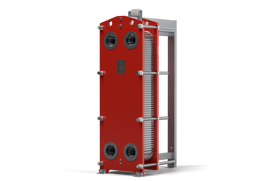

Standard plate heat exchangers

Standard plate heat exchangersSONDEX® standard plate heat exchangers are the ideal choice for a wide range of applications across numerous market segments. We have the largest plate portfolio in the world, and customize each heat exchanger to meet your exact requirements. Innovative technologies and smart design make our traditional plate heat exchangers a stellar investment.

The Outcome

Simplifying maintenance with Turbocor® compressors

Recover heat and save fuel costs with a Plate Heat Exchanger

Intelligent solutions give greater control

ICF block type valves increase plant efficiency

Simplifying maintenance with Turbocor® compressors

Ananda’s final objective was to simplify maintenance, and a Danfoss Turbocor® compressor – our highly reliable and energy-efficient oil-free compressor series – helped the company meet this requirement. Working together with heat exchangers and titanium tubes, this oil-free system helps avoid leakages as raw sea water is filtered and cooled for this application. Above all, Danfoss’s technology has fewer moving parts, minimum service intervals, consistent performance over time, and no performance loss due to oil degradation

Recover heat and save fuel costs with a Plate Heat Exchanger

After installing the super heater with Plate type Heat Exchange, Ananda Foods can heat water to 55°C without making any investments in electric heating. This is possible because the system recovers heat from the compressor discharge gas, which is used to heat water for free, saving fuel costs.

Intelligent solutions give greater control

Ananda Foods uses Danfoss’ GDA sensors and central control solutions to automate its ammonia gas detection system. The IPS 8 intelligent purging system – an intelligent, automated solution – helps Ananda keep condensing pressure under control.