The transport sector is responsible for one quarter of global emissions, and the majority is linked to passenger vehicles. Together, Danfoss and ZF will accelerate the electrification of the global car industry and transform the sector for a sustainable future.

“One quarter of the overall emissions is a significant amount”, says Julian Fieres, Head of Sales and Strategy with the Division E-Mobility at ZF Friedrichshafen AG, one of the world’s largest automotive suppliers. He adds, “the majority of these emissions are clustered in metropolitan areas with heavy traffic. As a result, the air quality in over 100 mega cities around the globe is considered unhealthy by the World Health Organization.”

“What really stood out to me,” explains Julian, “were the NASA satellite pictures that were taken of these cities before and after the COVID-19 lockdowns. The reduction of emissions due to reduced mobility really became visible. I am someone who deals with emission reduction technology within the transport industry on a daily basis, but seeing these images made me realize that this is the cleanest our cities have been in over a century – an impressive case for the change needed. I believe that the electrification of transport is a key contributor for a healthier and greener future.”

An industry at a tipping point

To meet the climate goals set out by the Paris Agreement and curb CO2 emissions by 28%, we need to accelerate the electrification of the transport sector. The automotive industry is at a tipping point. In 2019, sales of electric cars have exceeded 2 million vehicles, surpassing 2018 – already a record year. While they accounted for only 2.6% of global car sales and 1% of the global car stock in 2019, sales of electric cars have registered a 40% year-on-year increase.

To further support the large-scale adoption of electric vehicles, consumers need confidence that the car provides the necessary range, that it is affordable, and that the right charging infrastructure is in place - preferably from a renewable energy source. “The key for both range and price,” explains Siegbert Haumann, Vice President of Global Sales at Danfoss Silicon Power, “is an affordable energy storage option, as well as an efficient electrical drive train. In a car, that is the inverter and the electrical machine.”

The technology enabling the transformation

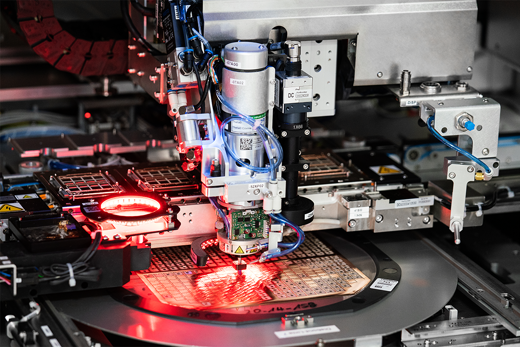

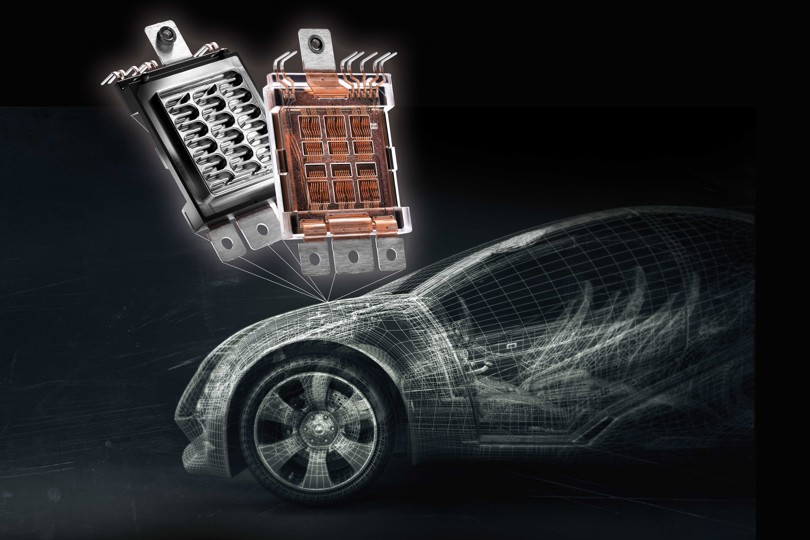

For both Hybrid Electric Vehicles (HEV) and Electric Vehicles (EV), developments within automotive technology are focusing increasingly on the electrification of the drivetrain. The drivetrain is the part of the vehicle that connects the transmission to the drive axes, making sure the wheels of the car are turning. A core component of an electrified drivetrain is the semiconductor power module. It is considered the heart of the inverter.

“Its purpose is to convert the AC energy from the electrical grid to DC energy, which is stored in the battery and then again to AC energy in the motor of the car in the most efficient way,” says Siegbert. This energy conversion process has undergone more than 25 years of continuous improvements. With new materials like Silicon Carbide (SiC), the size of the inverter will shrink, while the efficiency of the power conversion will further improve, and with that extend the range of electric vehicles.

“To a large extent, the advancements in the EV industry were made possible through radical innovation, and quite a few of them have been developed and introduced by Danfoss Silicon Power,” says Swantje Oldörp, Project Office Director, Danfoss Silicon Power, Research & Development. She adds, “currently, the most exciting technological developments are related to SiC MOSFET.”

SiC MOSFET have the biggest benefits when cruising and operating at low currents, which is where EVs operate most of the time, except for short acceleration phases. Going forward, SiC-based inverters will be able to improve the efficiency of the drivetrain by up to 7%, which results in range extension at equal battery size and thereby increased mileage of the EV at a competitive cost point.

Together for a greener future

When Danfoss and ZF decided to join forces to jointly develop e-mobility solutions, both wanted to accelerate the transformation of the automotive industry. “Danfoss with its entrepreneurial heritage and a pioneer in the design of advanced power modules, and ZF as one of the leading automotive system suppliers,” explains Swantje, “combine real strengths in technology and market access and are both driven by long-term sustainable success.”

“Danfoss is a technological leader in power modules with a great reputation and a long-standing tradition. We have been doing business together for several years now, and share a lot of the same values,” says Julian. He adds, “it was a logical step for us to continue the partnership and further drive innovation at the integration of power modules in our systems, moving our focus to plug-in hybridization and battery electrification across the value chain.”

Making electric transport a driver of economic recovery

The current crisis is not just a challenge, but an opportunity to accelerate the transformation of the transport sector. Technologies for e-mobility will drive the transformation of an entire industry within just a decade and enable the production and use of electric vehicles at a large scale. This will not just benefit the climate and reduce CO2-emissions. Engineers and many other job profiles will be needed, creating 1 million additional employment opportunities by 2030.

“This is a unique opportunity for a green restart of our society, and with that a significant potential from an economic and an environmental point of view,” explains Siegbert. “Together with ZF, we are reinventing transportation.”

This is where the electrification of transport starts

To power up the fast-growing fleet of electric vehicles Danfoss developed a cutting-edge power module technology platform for traction applications – the DCM™1000.