Position sensors for mobile hydraulic solutions

Danfoss is taking functional safety to the next level with a full program of state-of-the-art rotary position sensors, wire position sensors, and inclination sensors.

All variants come as both single and redundant sensor types, making the complete portfolio suitable for safety-critical applications.

For more than 30 years, Danfoss has delivered reliable, robust, and cost-effective sensor technologies for leading mobile hydraulic producers in the off-highway industry. With a complete program of hydraulic position sensors, Danfoss covers all machine types. Thus, OEMs are provided with unrivaled flexibility and scalability to meet both safety as well as environmental regulations.

Features and benefits

Hall effect technology (Rotary and wire sensors programs)

MEMS technology (Inclination program)

Single or redundant

Output: CANopen, SAE J1939 or Ratiometric

IP Protection Level: IP67 – IP69K with female mating connector

Position sensors in action

See our position sensors being put to the test at our Application Development Center in Nordborg, Denmark.

Reaching new heights in sensor reliability

PLUS+1® compliant

All sensors are PLUS+1® compliant. With simple and intuitive interfaces, this software platform offers seamless integration with development and service tools, to bring products faster to market while making it easy to keep machines current with parameter adjustments and software updates. Furthermore, real-time, remote access makes staying up to date even easier.

Documents

| Type | Name | Language | Valid for | Updated | Download | File type |

|---|---|---|---|---|---|---|

| Operating guide | DST X510 and DST X520 Rotary position sensors SAE J1939 | English | Multiple | 06 Dec, 2019 | 2.5 MB | |

| Operating guide | DST X510 and DST X520 Rotary Sensor CANopen | English | Multiple | 06 Dec, 2019 | 898.9 KB | |

| Operating guide | DST X710 Entry level inclination sensor CANopen Operating guide | English | Multiple | 01 May, 2019 | 1.1 MB | |

| Operating guide | DST X720 Mid level inclination sensor | English | Multiple | 01 May, 2019 | 1.1 MB | |

| Operating guide | DST X730 Top level inclination sensor | English | Multiple | 01 May, 2019 | 983.1 KB | |

| Data sheet | Inclination position sensor, type DST X710 | English | Multiple | 26 Feb, 2021 | 2.7 MB | |

| Data sheet | Inclination position sensor, type DST X720 | English | Multiple | 03 Mar, 2021 | 11.6 MB | |

| Data sheet | Inclination position sensor, type DST X730 | English | Multiple | 03 Mar, 2021 | 4.4 MB | |

| Operating guide | Operating guide DST X800 wire position sensor | English | Multiple | 01 May, 2019 | 491.8 KB | |

| Data sheet | Rotary position sensor, type DST X510 | English | Multiple | 26 Feb, 2021 | 1.9 MB | |

| Data sheet | Rotary position sensor, type DST X520 | English | Multiple | 26 Feb, 2021 | 1.3 MB | |

| Data sheet | Wire position sensor, type DST X800 | English | Multiple | 26 Feb, 2021 | 4.4 MB |

Product range

-

if (isSmallPicture) {

DST X800 series, wire position sensors

DST X800 series, wire position sensorsDanfoss DST X800 wire position sensor is developed to ensure a robust and high-performance solution for applications. The stability control of e.g. a crane, telehandler or aerial platform is kept under control with draw wire sensors that determine the withdrawal of lateral stabilizers at different positions; on same applications the draw wire on the boom. couldevent overturn of the machine.

-

if (isSmallPicture) {

DST X710, X720 and X730 series, inclination sensors

DST X710, X720 and X730 series, inclination sensorsDanfoss program of inclinometer sensors are developed to ensure a robust and high-performance solution for applications such as agricultural- and construction machines, as well as material handling equipments. These sensors are typically used in safety applications in order to keep the inclination of a machine, or just a part of it, a safety zone for working people, under control.

-

if (isSmallPicture) {

DST X510 and X520 series, rotary position sensors

DST X510 and X520 series, rotary position sensorsThese sensors are able to detect angles from ±15° up to 360° e.g. pedal accelerator, front or rear steering, suspension position, or cabin rotation.

Articles

The expanding demand for sensors

The demand for sensor technology is rapidly expanding. To comply with safety as well as environmental regulations, mobile hydraulic producers require more and more sensors in all machine types. Choosing the right sensor is crucial. We have made a checklist of key things to consider in your sensor specification.

Related applications

-

if (isSmallPicture) {

Agriculture

AgricultureFarmers need agricultural machines that deliver the same high productivity every season. Hydraulic solutions from Danfoss ensure world-class performance from each machine, and a comfortable, stress-free working environment for their operators.

-

if (isSmallPicture) {

Construction

ConstructionSpace is limited on construction sites, and there are people working everywhere. Contractors need machines that can safely maneuver in a tight spot. At the same time they still need to be powerful enough to get the job done. At Danfoss, we deliver the components, software, and controls that enable your machines to run safely, efficiently and effectively.

-

if (isSmallPicture) {

Crane and material handling

Crane and material handlingCranes and other large handling machines are required to operate within very specific load ranges. Danfoss provides pressure transmitters that supply load limiting systems with crucial data, safeguarding your equipment, your load, and your operator.

-

if (isSmallPicture) {

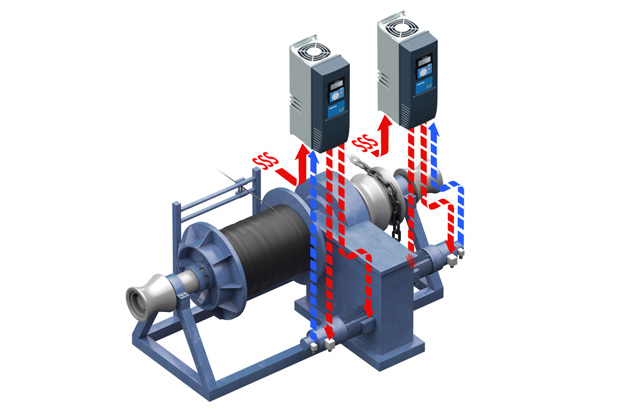

Drives for cranes in mining and mineral processing

Drives for cranes in mining and mineral processingTo optimize crane and hoist performance, Danfoss offers flexible control strategies combined with energy efficiency, operating within stringent safety requirements.

-

if (isSmallPicture) {

Drives for marine winches and cranes

Drives for marine winches and cranesBy running winches and cranes on an electric motor you can achieve energy savings, low noise operation and no risk of hydraulic oil overheating or leaks.

-

if (isSmallPicture) {

Forestry

ForestryRough, sloping terrain and cramped working conditions call for robust and reliable forestry machines. We make sure you can manage everything from cutting trees and transport to preparing the forest floor for replanting. We have the smart hydraulic solutions your machines need for precise and efficient forestry operations.