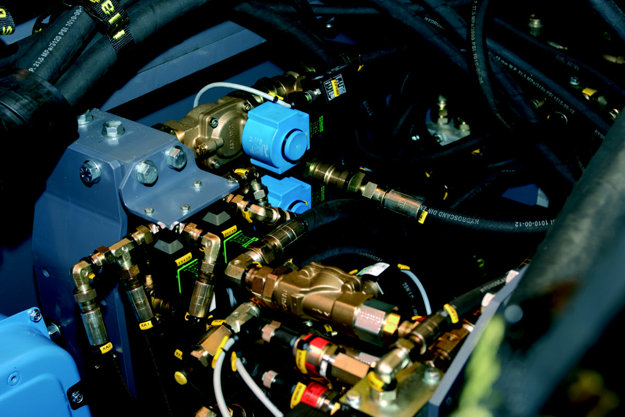

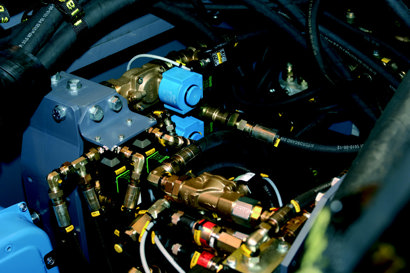

Most industrial machines are at the mercy of nature, exposed to harsh, unpredictable elements, and expected to run at peak performance. Danfoss bearing temperature sensors are specifically designed for accurate temperature measurement in mobile hydraulic, wind turbine, and marine engine room applications.

Engineered for those environments where reliability, longevity, and accuracy are crucial, our bearing temperature sensors help collect data to improve performance while optimizing predictive maintenance.

Our bearing temperature sensors are fitted with an adjustable spring-loaded protection tube that always ensures metallic contact between the bearing and the sensor. This makes them ideal for monitoring bearing temperatures in applications where there’s a risk of overheating, such as:

- Engine bearings

- Gearbox bearings

- Power transmission bearings

Features and benefits

All designs are based on Pt 100 / Pt 1000 / NTC technology

Sensor tube and pocket material: AISI 316 Ti

Temperature range -50 – 200 °C

Quick response time is achieved by placing the sensor element at the very tip of the sensor tube

All sensor tube and pocket material is made of AISI 316 Ti

Get the highest degree of performance with bearing temperature measurement

In our latest article, we unpack why bearing temperature sensors are small but vital components in massive industrial applications

Wind turbine brochure

Learn more about our product offerings for the wind industry.

Documents

| Type | Name | Language | Valid for | Updated | Download | File type |

|---|---|---|---|---|---|---|

| Data sheet | Bearing temperature sensor MBT 5310 | Russian | Multiple | 04 Aug, 2022 | 924.0 KB | |

| Data sheet | Bearing temperature sensor MBT 5310 | French | Multiple | 04 Aug, 2022 | 922.4 KB | |

| Data sheet | Bearing temperature sensor MBT 5310 | Spanish, Castilian | Multiple | 04 Aug, 2022 | 920.4 KB | |

| Data sheet | Bearing temperature sensor MBT 5310 | Chinese (CN) | Multiple | 04 Aug, 2022 | 1.0 MB | |

| Data sheet | Bearing temperature sensor MBT 5310 | German | Multiple | 04 Aug, 2022 | 921.9 KB | |

| Data sheet | Bearing temperature sensor, MBT 3310 | Spanish, Castilian | Multiple | 10 Feb, 2020 | 228.3 KB | |

| Data sheet | Bearing temperature sensor, MBT 3310 | Chinese (CN) | China | 11 Feb, 2020 | 253.3 KB | |

| Data sheet | Bearing temperature sensor, MBT 3310 | English | Multiple | 30 Jul, 2024 | 352.1 KB | |

| Data sheet | Bearing temperature sensor, MBT 3310 | French | Multiple | 10 Feb, 2020 | 240.4 KB | |

| Data sheet | Bearing temperature sensor, MBT 3310 | German | Multiple | 30 Jul, 2024 | 586.2 KB | |

| Data sheet | Bearing temperature sensor, MBT 3310 | Russian | Central Asia Unit | 11 Feb, 2020 | 236.4 KB | |

| Data sheet | Mini bearing temperature sensor, Type MBT 2310 | English | Multiple | 17 Mar, 2022 | 750.2 KB | |

| Data sheet | Temperature sensor, type MBT 5310 | Polish | Multiple | 04 Aug, 2022 | 922.4 KB | |

| Data sheet | Temperature sensor, type MBT 5310 | English | Multiple | 26 Feb, 2021 | 943.1 KB |

Approvals

| Type | Name | Language | Valid for | Updated | Download | File type |

|---|---|---|---|---|---|---|

| Marine Safety Certificate | ABS 20-1993817-PDA | English | Multiple | 17 Feb, 2025 | 1.7 MB | |

| Marine Safety Certificate | BV 06512-F1 BV | English | Multiple | 27 Nov, 2024 | 574.2 KB | |

| EU-UK Declaration | Danfoss EU-UK 084R1019.04 | English | Multiple | 18 Mar, 2025 | 3.0 MB | |

| Explosive Safety Certificate | DEMKO 12CA69359 | English | Multiple | 27 Nov, 2024 | 33.4 KB | |

| Marine Safety Certificate | KR DLN 34014-AE002 | English | Multiple | 27 Nov, 2024 | 419.5 KB | |

| Marine Safety Certificate | RINA ELE123820XP | English | Multiple | 27 Nov, 2024 | 1.0 MB |

Related solutions

-

if (isSmallPicture) {

Pressure and temperature monitoring

Pressure and temperature monitoringPressure and temperature monitoring sensors, transmitters, electronic pressure switches and solenoid valves recommended for hydraulic applications.

-

if (isSmallPicture) {

Wind turbines

Wind turbinesThe general trend towards larger wind turbines at remote sites, often offshore, places new demands on the turbine equipment and sets new standards for maintenance during the turbine life cycle.

The performance of your wind turbine relies on the quality of its components.

Related applications

-

if (isSmallPicture) {

Air compressors on ships

Air compressors on shipsDanfoss offers a full package of pressure and temperature controls for compressed air systems, ensuring all time available air for safe journeys on the vessel.

-

if (isSmallPicture) {

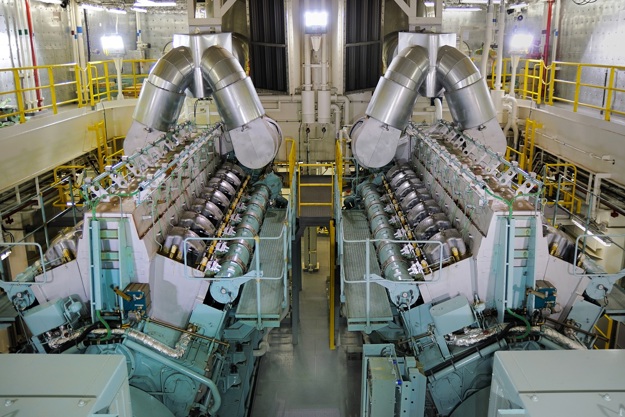

Engines

EnginesThe engine is the heart of the ship. Reliable and efficient engines rely on precise control of pressure and temperature - that is what Danfoss products ensure.

-

if (isSmallPicture) {

Exhaust gas treatment

Exhaust gas treatmentThe environment in exhaust gas systems is extremely harsh, and only the most robust components survive - this is what Danfoss marine products are d optimized for.

-

if (isSmallPicture) {

Fuel, oil and water treatment

Fuel, oil and water treatmentSafe operation onboard the vessel requires vital support systems, e.g. cooling water and fuel oil. Danfoss marine products can support all of these functions.

-

if (isSmallPicture) {

Machinery room

Machinery roomFind more information about which marine approved products and solutions Danfoss Sensing Solutions can provide and recommend for marine applications.

-

if (isSmallPicture) {

Propulsion system

Propulsion systemConvert the power from the marine engine to cut down energy consumption with dedicated and marine approved pressure and temperature controls from Danfoss.