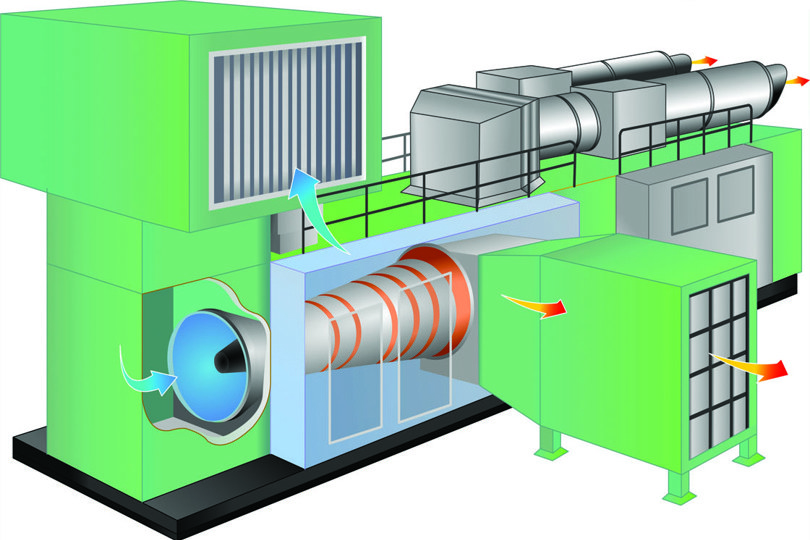

Pumps to improve system design in Gas Turbines

Danfoss PAHT G pumps were developed specifically for gas turbine applications, to provide outstanding reliability in operation with aggressive DI / ultra pure water. The pumps are particularly well suited for: wet compression, NOx emission reduction, and inlet fogging.

Even though the pumps' long service intervals and high efficiency are already attractive, the most significant advantages of PAHT G extend beyond the pumps themselves, by enabling more cost-effective and smarter engineering for Danfoss customers. Because the Danfoss pumps operate by direct flow control and have low maintenance requirements, system designs are often improved. E.g., systems can be made lower in capital cost (by removing the need for expensive components), more cost-effective in operation (by avoiding oil and its associated hassles), more compact (as the lightest and most compact pumps in the industry), and less complex (simplifying system controls due to direct flow control).

PAHT G products handle flows ranging from 0.7 to 354 l/min (0.2 to 93.5 gpm) and pressures up to 160 barg (2,321 psig). All PAHT G pumps are available with ATEX certification.

Features and benefits

Direct linear flow control, which enables system cost reduction—and furthermore simplifies controls, eliminating the need for periodic re-calibration

Capability to continue functioning when the turbine operates at high turn-down, without risk of damage

Long service intervals—up to 8,000 hours can be expected.

Low energy costs, due to its highly efficient axial piston design.

No hassle, risks, or costs associated with oil leaks—thanks to the pump’s ultra-clean technology where no oil is needed.

Easy installation and service, due to smart and compact design.

Pumps for gas turbine applications

The unique Danfoss high-pressure pump design reduces costs, complexity, and hassle for gas turbine applications.

Gas turbine applications

Explore the benefits of using PAHT G pumps for your applications

Product range

-

if (isSmallPicture) {

PAHT G 2-6.3 high pressure pump

PAHT G 2-6.3 high pressure pumpPressure range: Max. outlet pressure: 100 barg/1,450 psig

Inlet pressure, cont.: 0-4 barg/0-58 psig

Flow range: 0.7 to 18.1 l/min - 0.2 to 4.7 gpm

Speed: 1,000 to 3,000 rpm -

if (isSmallPicture) {

PAHT G 10-12.5 high pressure pump

PAHT G 10-12.5 high pressure pumpPressure range: Max. outlet pressure: 140 barg/2,031 psig

Inlet pressure, cont.: 0-4 barg/0-58 psig

Flow range: 7.6 to 25.8 l/min - 2.0 to 7.2 gpm

Speed: 1,000 to 2,400 rpm -

if (isSmallPicture) {

PAHT G 256-308 high pressure pump

PAHT G 256-308 high pressure pumpPressure range: Max. outlet pressure: 120 barg/1,740 psig

Inlet pressure, cont.: 2-6 barg/29-87 psig

Flow range: 89.6 to 354.2 l/min, 23.3 to 92.1 gpm

Speed: 450 to 1,250 rpm -

if (isSmallPicture) {

PAHT G 50-90 high pressure pump

PAHT G 50-90 high pressure pumpPressure range: Max. outlet pressure: 80 barg/1,160 psig (PAHT 50), 160 barg/2,321 psig (PAHT 63-90)

Inlet pressure, cont.: 0-6 barg/0-87 psig

Flow range: 28.6 to 149.6 l/min - 7.4 to 38.9 gpm

Speed: 700 to 1,800 rpm -

if (isSmallPicture) {

PAHT G 20-32 high pressure pump

PAHT G 20-32 high pressure pumpPressure range: Max. outlet pressure: 100 barg/1,450 psig (PAHT 20), 160 barg/2,321 psig (PAHT 25-32)

Inlet pressure, cont.: 0-6 barg/0-87 psig

Flow range: 10.8 to 73.5 l/min, 2.8 to 19.1 gpm

Speed: 700 to 2,400 rpm

Documents

| Type | Name | Language | Valid for | Updated | Download | File type |

|---|---|---|---|---|---|---|

| Brochure | Optimize the TCO of gas turbines with PAHT G high-pressure water pumps | English | Multiple | 28 Jun, 2019 | 2.7 MB | |

| Brochure | Optimize the TCO of gas turbines with PAHT G high-pressure water pumps | Turkish | Turkey | 09 Feb, 2021 | 45.1 MB | |

| Brochure | Optimize the TCO of gas turbines with PAHT G high-pressure water pumps | French | Multiple | 26 Jan, 2021 | 1.1 MB | |

| Data sheet | PAHT G 2-308 pumps Data sheet | German | Multiple | 20 Jan, 2023 | 5.4 MB | |

| Data sheet | PAHT G 2-308 pumps Data sheet | Italian | Multiple | 20 Jan, 2023 | 2.8 MB | |

| Data sheet | PAHT G 2-308 pumps Data sheet | English | Multiple | 27 Feb, 2024 | 5.8 MB | |

| Data sheet | PAHT G 2-308 pumps Data sheet | French | Multiple | 20 Jan, 2023 | 2.7 MB |

Related products

-

if (isSmallPicture) {

VLT® AQUA Drive FC 202

VLT® AQUA Drive FC 202VLT® AQUA Drive FC 202 controls all types of pumps and comes equipped with a cascade controller.

-

if (isSmallPicture) {

VLT® AutomationDrive FC 301 / FC 302

VLT® AutomationDrive FC 301 / FC 302The VLT® AutomationDrive FC 301 / FC 302 is designed for variable speed control of all asynchronous motors and permanent magnet motors. It comes in a standard version (FC 301) and an advanced high dynamic version (FC 302) with additional functionalities.

-

if (isSmallPicture) {

Industrial temperature sensors

Industrial temperature sensorsThe Danfoss range of temperature sensors for industrial purposes is based on decades of global experience within the marine industry and in refrigeration plants - undoubtedly some of the toughest environments around. Even in these demanding surroundings you can trust our products; they have a long life thanks to their robust design.

-

if (isSmallPicture) {

Industrial pressure transmitters

Industrial pressure transmittersDanfoss pressure transmitters help you keep demanding industrial processes under control. Accurate, robust and built for long life, they perform reliably day after day, even in the harshest environments.

Related applications

-

if (isSmallPicture) {

Gas turbines

Gas turbinesThe unique Danfoss high-pressure pump design provides advantages for gas turbine applications including NOx reduction, inlet fogging and wet compression. Advantages such as energy efficiency, long service life and compact design.

Learning

Pump animation

Learn how an axial piston pump works in this video animation.