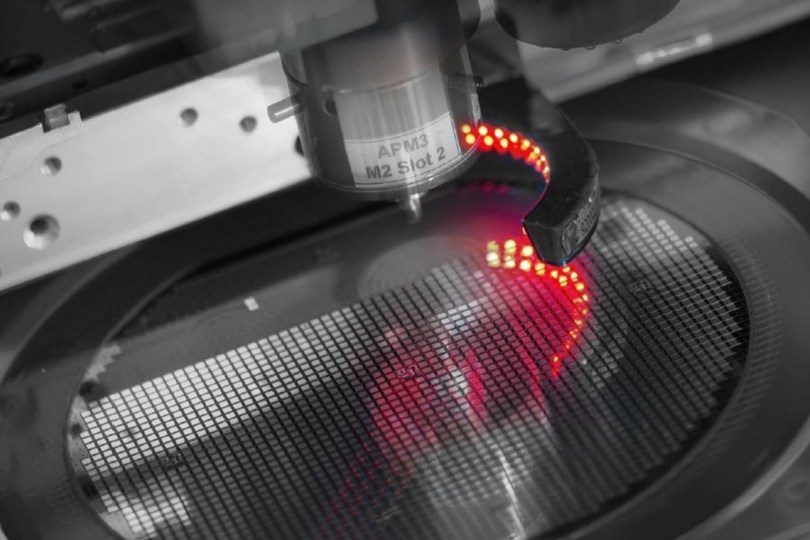

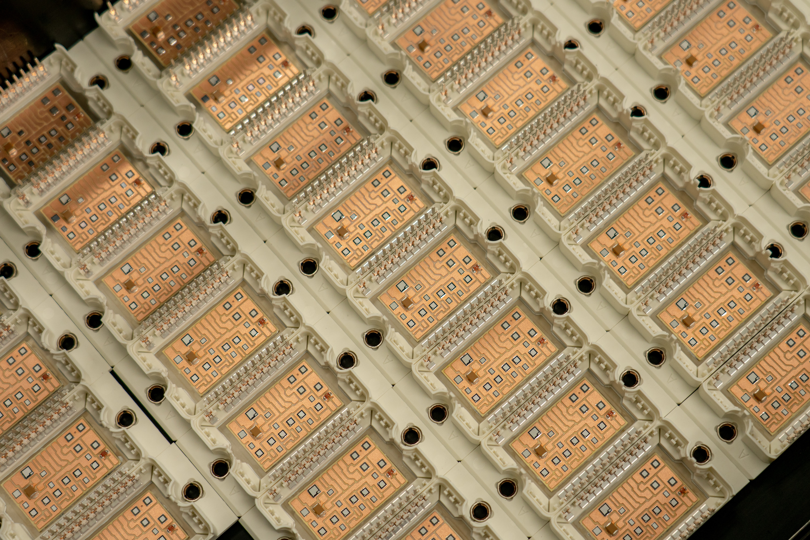

Engineering tomorrow’s IGBT power modules

For over three decades, Danfoss has been helping top-tier manufacturers and system suppliers meet stringent reliability, design and cost targets by developing customized IGBT power modules for tomorrow's e-mobility, energy and industrial applications.

Our winning technologies

Technology and innovation are more than just buzzwords. Being a market leader in packaging of power semiconductors, we have developed a second-to-none portfolio of tried and tested packaging technologies that address the most challenging aspects of advanced power electronics:

Tailored to your needs

Tailored solutions means that you can maintain a competitive edge by having the flexibility to move with your customers’ changing demands. It also means trusting your suppliers to deliver exactly what you need, when you need it and at the right cost-level. In Danfoss, we focus solely on creating solutions that are uniquely tailored to your application.

FAQs

Your power module benefits

Customized to your exact needs

Tried, tested and patented technologies for higher performance

Reduced semiconductor surface by maximizing the potential of Si enabling cost-effective solutions

Supply security through chip independency

Related products

Danfoss SiC power modules

Danfoss offers a wide range of innovative custom-made SiC power module solutions for industrial, e-mobility and energy applications.

Related applications

-

if (isSmallPicture) {

Electric traction inverter (HEV/EV)

Electric traction inverter (HEV/EV)For decades, Danfoss has been helping top tier automotive manufacturers and system suppliers meet stringent reliability, design and cost targets.

-

if (isSmallPicture) {

Industrial motor drives

Industrial motor drivesMotor drives are the backbone of modern global industry. They are well hidden, but nevertheless they play a key role. For decades, Danfoss has been designing, developing and manufacturing customized IGBT power modules for industrial motor drives.

-

if (isSmallPicture) {

Solar inverters

Solar invertersToday, Danfoss works together with some of the world's most innovative and successful solar inverter manufacturers with a common mission of lowering the cost of solar energy enabling a transition to a more sustainable future

How it works

The IGBT power module - how it works

Learn the basics of what an IGBT power module is, what it does and how it works.

Contact us

For further information please contact us