Over eight decades of proven performance

Airflex constricting clutches and brakes are the go-to solutions for heavy duty applications. Available in four different series spanning a range of sizes and features, you’ll find the perfect fit for grinding mills, marine propulsion, drill rigs, and much more.

- Long life - Rugged tire-like constricting tube

- Even wear - Force applied uniformly at optimum radius

- Many options - Wide torque capacity range

Four models excel at starting and stopping heavy-duty equipment in harsh conditions

- VC – Handles large inertia loads and sustained slippage on heavy-duty applications

- CB – The original and still a perfect fit for high-speed cyclic operations, coupling and general power transmission

- HEVC – Increased energy capacity allows for longer slip times in severe clutching and braking applications

- CM – specifically engineered for the marine industry on diesel-driven, reverse-reduction gears

How constricting elements work

Airflex constricting drum clutch and brake elements use a rugged, tire-like neoprene and cord tube that expands radially inward when pressurized. The expansion forces the friction surface against a cylindrical drum to create torque.

Force applied at maximum radius from axis

Instead of the reduced radius that occurs in plate clutches, constricting drum clutches concentrate the frictional force on the outside drum diameter to achieve maximum torque. The drum radius acts as the torque lever arm to generate and apply force uniformly around the drum circumference.

Features and benefits

Uniform contact velocity

In Airflex constricting drum clutches and brakes, friction shoe contact occurs across the cylindrical surface of the drum where the contact velocity is constant. This means Airflex constricting elements will have more consistent and lower rates of wear over plate-type clutches where the contact velocity varies across the friction plate face.

As friction surfaces wear, the tube simply expands farther, reducing the need for maintenance but not torque capacity.

As friction surfaces wear, the tube simply expands farther as needed. Normal wear does not reduce torque capacity, but does reduce maintenance requirements.

No lubrication required

Further reducing the need for regular maintenance, constricting drum clutches and brakes lack close-fitting sliding components so they do not need lubrication.

Operates in any plane

Unlike plate clutches that operate best in a vertical plane, a constricting design combined with its centrifugal effects allows for clutch operation in any plane.

Product range

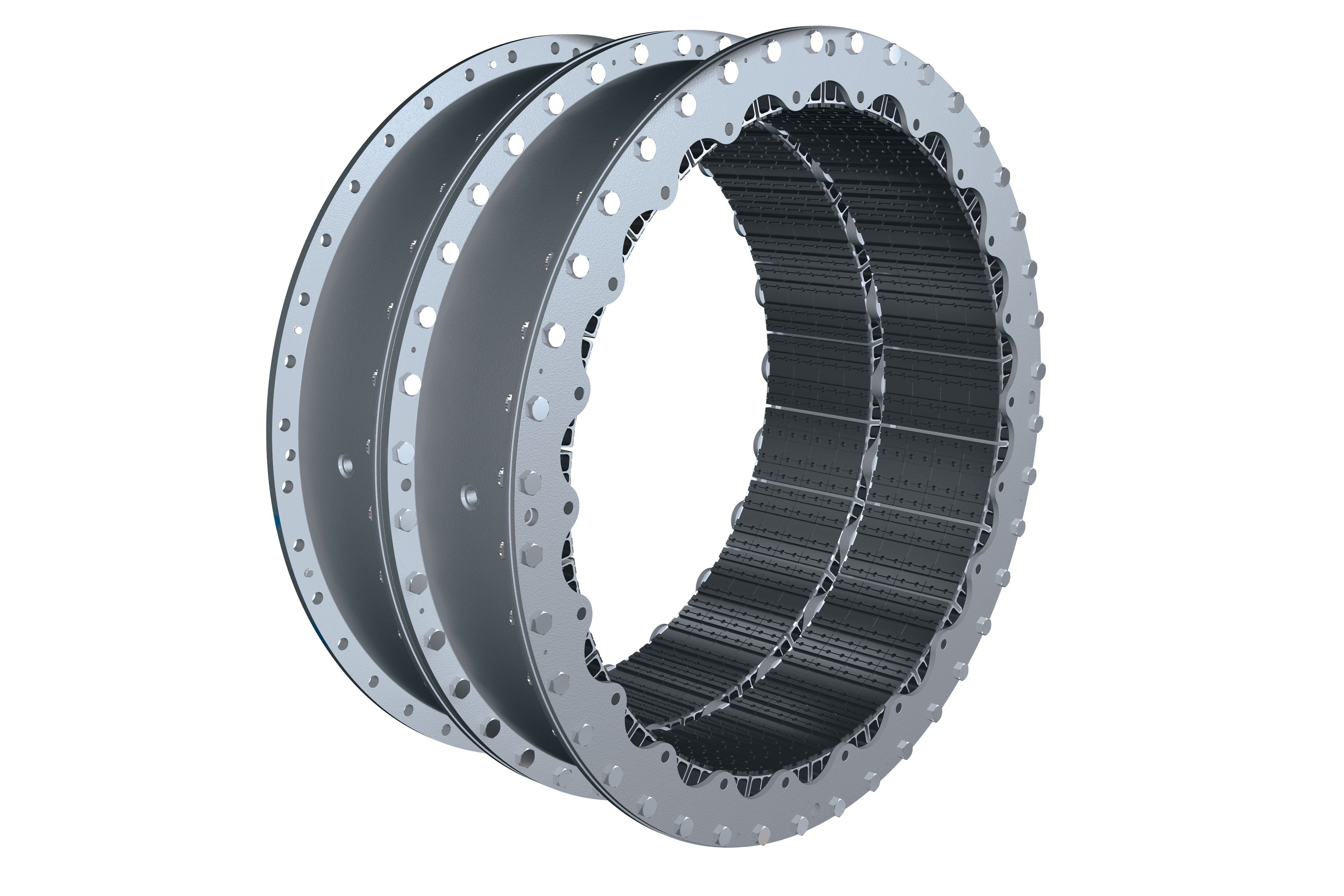

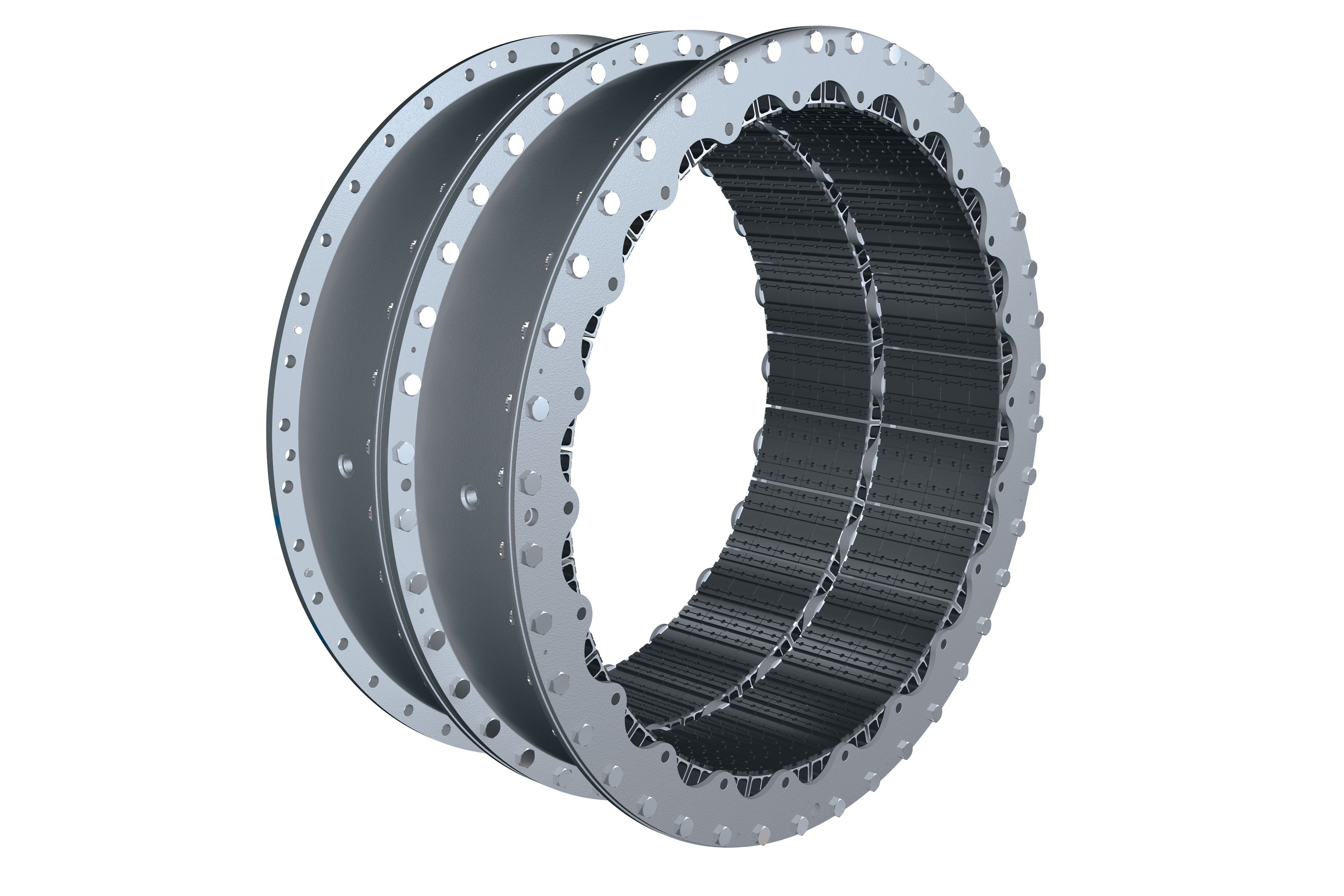

VC series

- Ventilated open construction dissipates heat rapidly

- Shock-free engagement when used as a clutch

- Highly serviceable with all parts available for replacements

- Torque capacities available up to 9,300,000lb•in (1,050,759 N•m)

- Available in 24 sizes in narrow or wide and single or dual configurations

CB series

- Tube is the only moving component

- Cushioned action protects drive components

- Flexible coupling

- Torque capacities up to 520,000 lb•in (58,800N•m)

- Available in 20 sizes

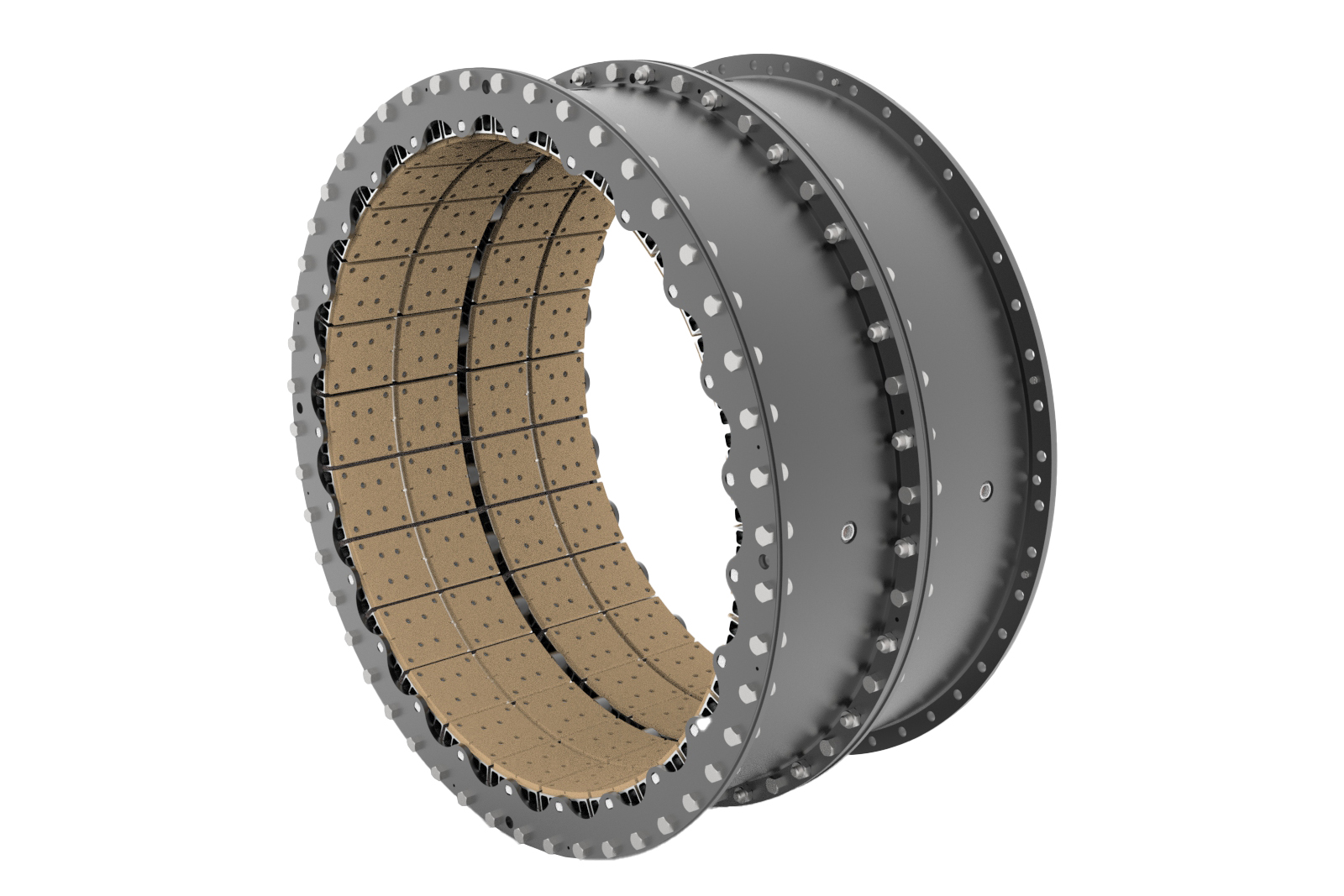

HEVC series

- Same basic features and size as VC elements but with 25% higher torque

- Allows for longer slip times

- Increased start times – over 15 seconds at highest energy

- Low friction wear for longer clutch life

- Torque capacities available up to 11,904,000 lb•in (1,344,971 N•m)

- Available in 6 sizes

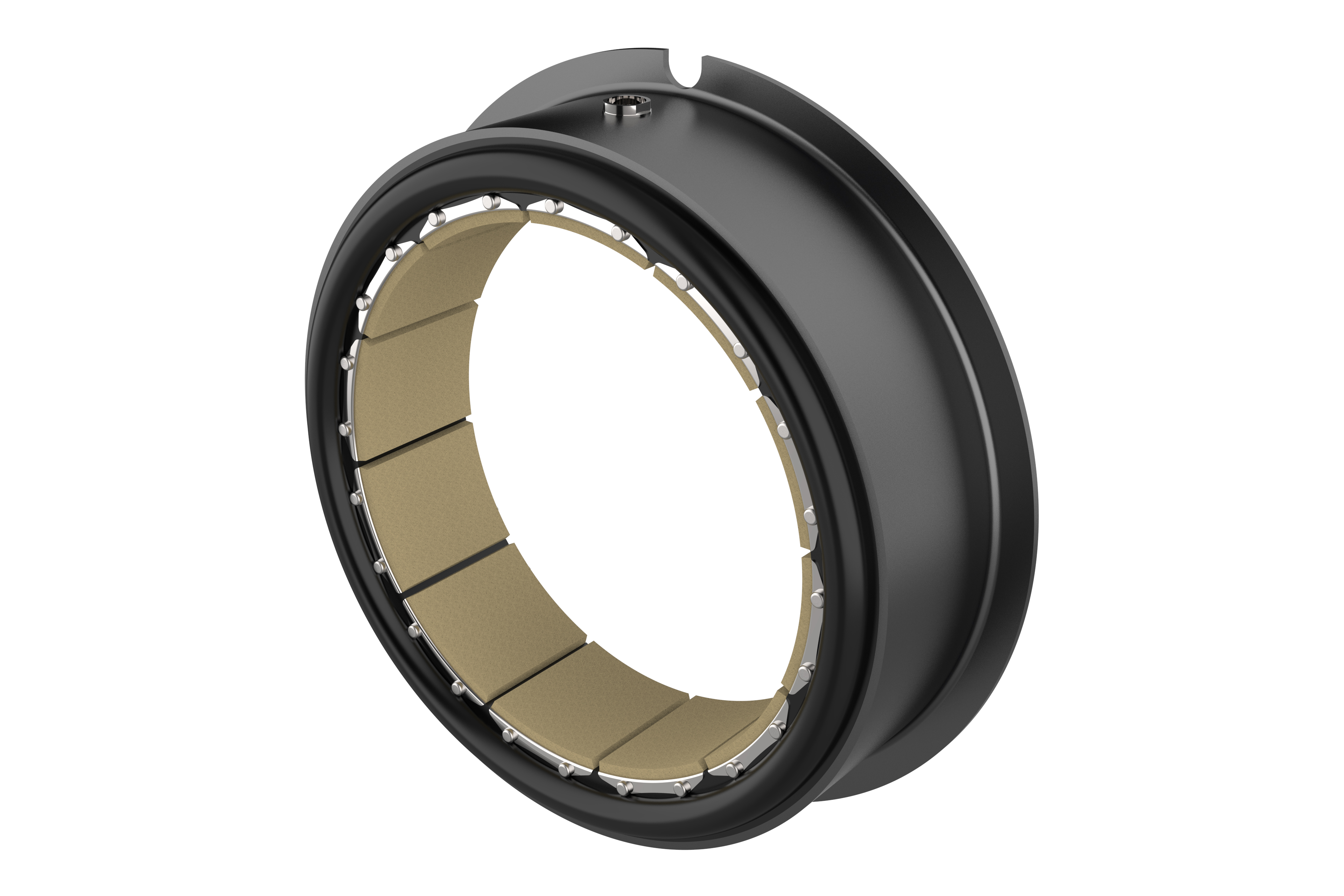

CM series

- Same basic features as CB elements

- Ventilated construction for greater heat dissipation

- Allows for double- and triple-element assemblies

- Torque capacities up to 613,000 lb•in (369,360 N•m)

- Available in 5 sizes

Documents

| Type | Name | Language | Valid for | Updated | Download | File type |

|---|---|---|---|---|---|---|

| Fact sheet | Airflex high energy ventilated constricting clutch | English | Multiple | 25 Aug, 2023 | 380.5 KB | |

| Brochure | Airflex Slip Detection Control Brochure | English | Multiple | 13 Jul, 2023 | 1.9 MB | |

| Brochure | Airflex® Industrial Clutch and Brake Product and Application Overview | English | Multiple | 30 Mar, 2023 | 1.4 MB |