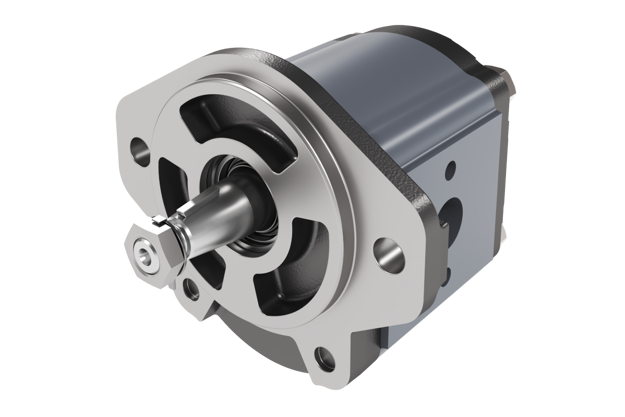

Evolutionary low noise patented gear pump technology

shhark® is the low noise external gear pump with outstanding performance guaranteed throughout the whole life of the pump.

With a simple but sophisticated design, we offer a gear pump that not only is quieter. It also has a unique advantage over the most popular low noise gear pump. The shhark® patented design guarantees the pump will remain silent after many hours of heavy-duty operation. This offers costs savings over traditional gear pump by eliminating costs associated with external noise reduction devices.

The shhark® design offers up to 10 dB noise reduction over regular gear pumps. It is ideal for application where low noise and high efficiency are required. Typical applications include tractors, indoor lift trucks, aerial platforms, construction equipment, material handling, agricultural and lifting devices.

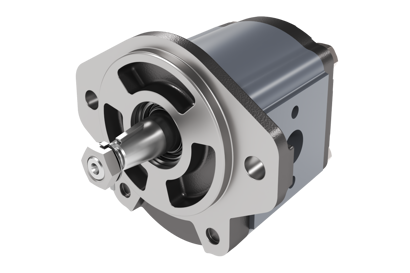

QUIETER PUMP – noise level emissions reduced by up to 10 dB(A)

LOW VIBRATION – flow pulsation reduced by a stunning 78%

DURATION – low noise performance guaranteed throughout the whole life of the pump

EFFICIENCY – higher efficiency compared to standard gear pumps

SAVINGS – cost, weight and footprint savings

LEGISLATION – helps meet legal NVH requirements

INTERCHANGEABLE – allows to fully replace our standard gear pumps

Related applications

-

if (isSmallPicture) {

Construction

ConstructionSpace is limited on construction sites, and there are people working everywhere. Contractors need machines that can safely maneuver in a tight spot. At the same time they still need to be powerful enough to get the job done. At Danfoss, we deliver the components, software, and controls that enable your machines to run safely, efficiently and effectively.

-

if (isSmallPicture) {

Crane and material handling

Crane and material handlingCranes and other large handling machines are required to operate within very specific load ranges. Danfoss provides pressure transmitters that supply load limiting systems with crucial data, safeguarding your equipment, your load, and your operator.

-

if (isSmallPicture) {

Forestry

ForestryRough, sloping terrain and cramped working conditions call for robust and reliable forestry machines. We make sure you can manage everything from cutting trees and transport to preparing the forest floor for replanting. We have the smart hydraulic solutions your machines need for precise and efficient forestry operations.

-

if (isSmallPicture) {

Heavy machinery

Heavy machineryThink about the heaviest challenges in the open mining, road building and construction industry. Tasks such as cutting through rock or the Arctic permafrost; compacting thick layers of hot asphalt. As well as lifting huge, prefabricated wall panels into place.

-

if (isSmallPicture) {

Lawn and turf

Lawn and turfLawn and turf machines must adapt to their surroundings and the season – becoming sweepers or snow blowers as required. At Danfoss, we make hydraulic solutions to provide that flexibility and ensure safe and efficient operation.

-

if (isSmallPicture) {

Road building

Road buildingAdvanced hydraulic systems from Danfoss deliver the machine performance that ensures road builders can meet their deadlines.

Related solutions

-

if (isSmallPicture) {

All-wheel steering

All-wheel steeringAll-wheel steering is one example of how Danfoss is at the forefront of machine versatility. This helps customers getting the most out of their equipment. Electrohydraulic steering system enables operators to manually adjust the steering mode, allowing them to best match machine performance to the task at hand.

-

if (isSmallPicture) {

Steering

SteeringAs the global market leader in steering components and systems, Danfoss equips everything from small lawn machines to the largest dump trucks.

-

if (isSmallPicture) {

Thermal management

Thermal managementDanfoss is here to help. With our complete fan drive solution, Danfoss is able to help you maximize available engine power. As well as, decrease fuel costs and increase operator productivity.

Documents

| Type | Name | Language | Valid for | Updated | Download | File type |

|---|---|---|---|---|---|---|

| Service guide | Gear Pumps and Motors Packaging and Recycling Information | Italian | Multiple | 11 May, 2023 | 437.3 KB | |

| Service guide | Gear Pumps and Motors Packaging and Recycling Information | English | Multiple | 11 May, 2023 | 428.8 KB | |

| Brochure | Open for Comfort - Protecting the Environment Danfoss NVH Technology | English | Multiple | 05 May, 2023 | 929.5 KB | |

| Data sheet | Shhark Low Noise Aluminum Gear Pumps Data Sheet | English | Multiple | 28 Apr, 2021 | 895.6 KB | |

| User guide | shhark® Aluminum Group 2 Pump Technical Information | Japanese | Japan | 27 Nov, 2024 | 7.0 MB | |

| User guide | shhark® Aluminum Group 2 Pump Technical Information | English | Multiple | 28 Apr, 2023 | 3.8 MB | |

| Data sheet | shhark® and Compact Multiple Pump Data Sheet | English | Multiple | 25 Jan, 2023 | 1.1 MB |

Related products

-

if (isSmallPicture) {

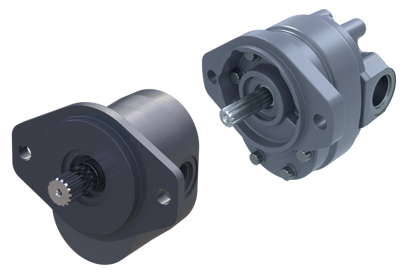

Lumi gear pumps

Lumi gear pumpsA solid product line for standard applications with unique design featuring cast iron flange and end cover for optimum reliability. Suitable for wide variety of applications that demands standard pump performance.

-

if (isSmallPicture) {

Rugid gear pumps

Rugid gear pumpsOur Rugid gear pumps are 20% smaller than conventional gear products, and give great power density in a small package. Typical applications are skid steer loaders and heavy-duty machines.

-

if (isSmallPicture) {

GearMe gear pumps

GearMe gear pumpsOur gear pumps are robust and reliable. They are the ideal choice for a wide range of applications. From small to medium and large off-highway vehicles, as well as for industrial applications. Low noise gear pumps are also available. They are the ideal solution for steering applications in cab-equipped mobile machines and for electric/hybrid machines.

News

-

if (isSmallPicture) {

Danfoss at the 36th China Refrigeration Exposition, leading the industry’s green transformation with innovative technologiesSunday, April 27, 2025

Danfoss at the 36th China Refrigeration Exposition, leading the industry’s green transformation with innovative technologiesSunday, April 27, 2025China Refrigeration Exhibition will take place at the Shanghai New International Expo Centre. Danfoss, a global leader in industrial and commercial refrigeration, will be presenting the latest product technologies and solutions under the theme of “Transition forward” at the exhibition stand E2D01. The exhibition will showcase the full range of products from the two business areas of air conditioning heat pumps and refrigeration, as well as six hot spot applications. In addition, this year marks the 30th anniversary of the launch of Danfoss Turbocor® magnetically suspended oil-free compressors. During the exhibition period, Danfoss will celebrate a grand ceremony and review the innovation history of Turbocor® magnetically suspended compressors, further demonstrating its contribution to leading efficient innovation, increasing customer competitiveness and driving sustainability in the industry.

-

if (isSmallPicture) {

Danfoss builds the world’s most livable labWednesday, April 23, 2025

Danfoss builds the world’s most livable labWednesday, April 23, 2025The new Danfoss House is the world's only multi-residential building of bricks and concrete to achieve the highest certification under the globally recognized DGNB standard.

-

if (isSmallPicture) {

Danfoss Power Solutions extends Thorx cam lobe motor family with new, improved design for track drivesMonday, April 7, 2025

Danfoss Power Solutions extends Thorx cam lobe motor family with new, improved design for track drivesMonday, April 7, 2025The Danfoss Thorx CLM 12 T cam lobe motor offers easier machine integration, a longer lifetime, and improved two-speed and parking brake technology.