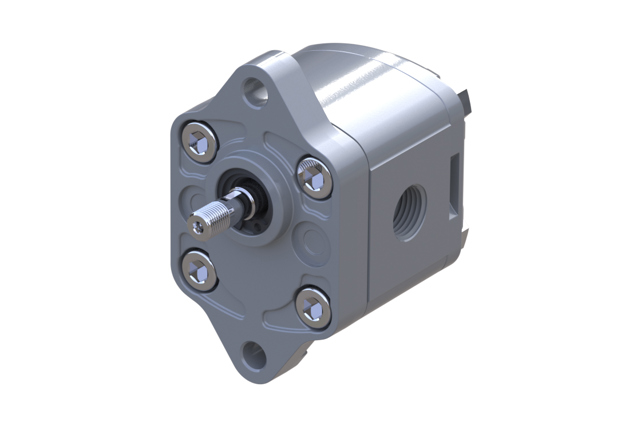

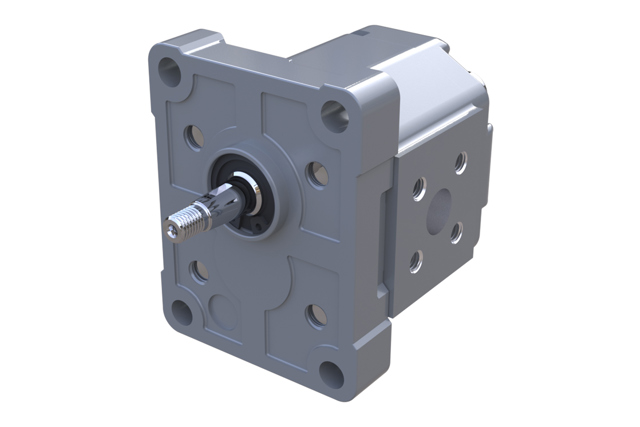

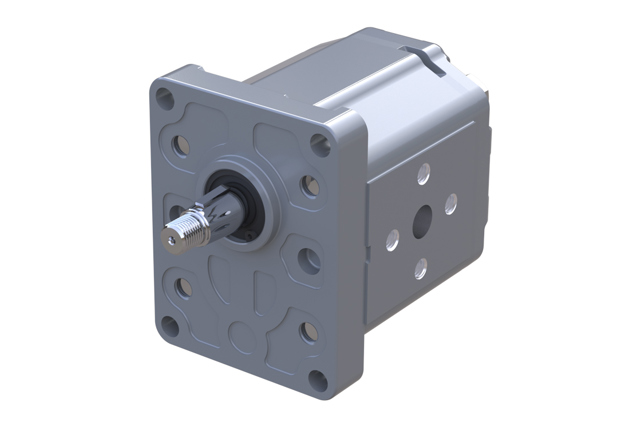

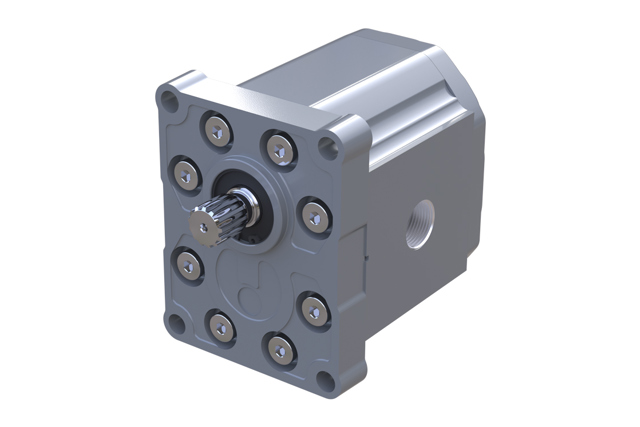

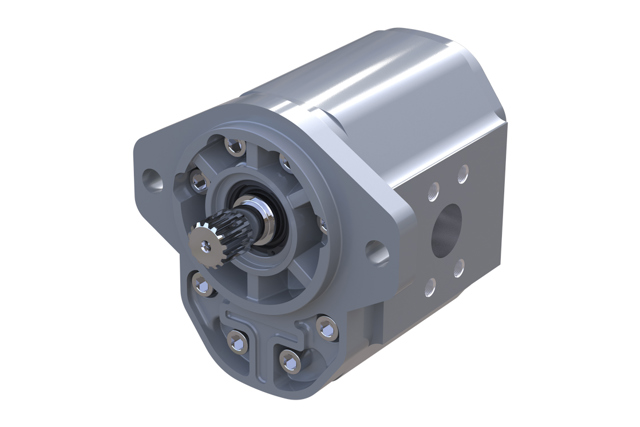

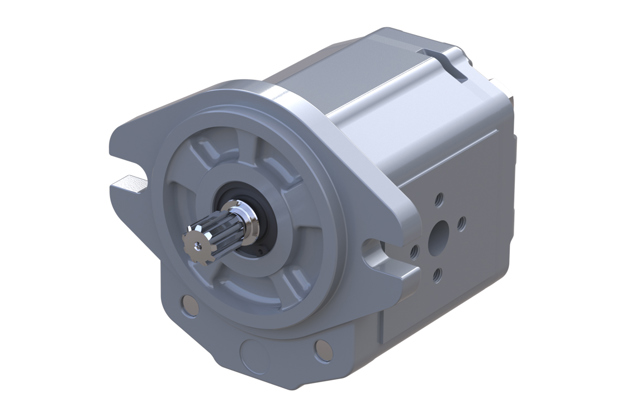

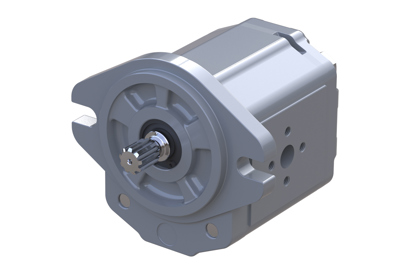

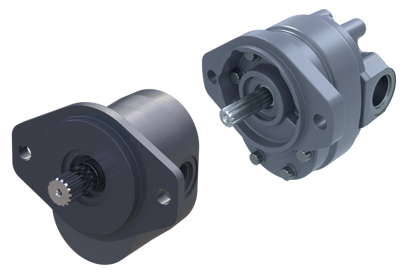

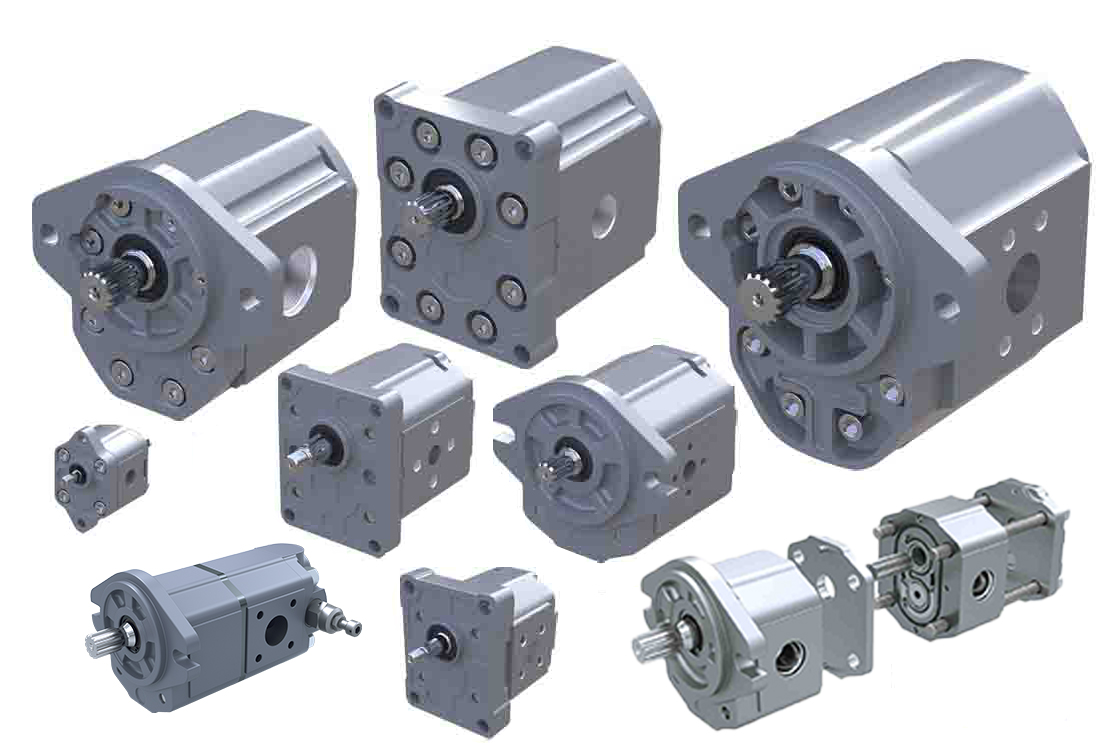

GearMe gear pumps

Our gear pumps are robust and reliable. They are the ideal choice for a wide range of applications - from small to medium and large off-highway vehicles, as well as for industrial applications.

- Pressure-balanced design, ensuring sealing pressure, adapts automatically to operating conditions for improved overall efficiency and minimum energy losses

- Minimized internal friction and perfectly fitting housing for an extended operating life

- Modular and short versions of multi-stage units for high flexibility and compactness

- Teflon® coated bushings for extended life under extreme temperature and pressure conditions

- A variety of integrated valve options

- One piece gear shaft construction

- Broad range of shaft drives, integrated valves, and side or rear port options gives great flexibility in system design.

- Internal spline design option for compactness

- Flex Program to ensure high customization in distribution

Documents

| Type | Name | Language | Valid for | Updated | Download | File type |

|---|---|---|---|---|---|---|

| Service guide | Gear Pumps and Motors Packaging and Recycling Information | Italian | Multiple | 11 May, 2023 | 437.3 KB | |

| Service guide | Gear Pumps and Motors Packaging and Recycling Information | English | Multiple | 11 May, 2023 | 428.8 KB | |

| User guide | GearMe Aluminum Group 0 and Group 1 Pump Technical Information | English | Multiple | 16 Feb, 2023 | 7.4 MB | |

| User guide | GearMe Aluminum Group 0 and Group 1 Pump Technical Information | Japanese | Japan | 27 Nov, 2024 | 10.4 MB | |

| User guide | GearMe Aluminum Group 2 Compact Multiple Pumps Technical Information | English | Multiple | 16 Feb, 2023 | 4.2 MB | |

| User guide | GearMe Aluminum Group 2 Flex Pump Technical Information | English | Multiple | 30 May, 2023 | 3.8 MB | |

| User guide | GearMe Aluminum Group 2 Single Pump Technical Information | Japanese | Japan | 27 Nov, 2024 | 8.5 MB | |

| User guide | GearMe Aluminum Group 2 Single Pump Technical Information | English | Multiple | 16 Feb, 2023 | 5.2 MB | |

| User guide | GearMe Aluminum Group 3 Pump Technical Information | Japanese | Japan | 27 Nov, 2024 | 7.8 MB | |

| User guide | GearMe Aluminum Group 3 Pump Technical Information | English | Multiple | 16 Feb, 2023 | 4.4 MB | |

| User guide | GearMe Aluminum Group 3 Pump Technical Information | Chinese (CN) | Multiple | 16 Feb, 2023 | 4.8 MB | |

| User guide | GearMe Aluminum Group 4 Pump Technical Information | English | Multiple | 16 Feb, 2023 | 5.0 MB | |

| User guide | GearMe Aluminum Group 4 Pump Technical Information | Japanese | Japan | 27 Nov, 2024 | 8.4 MB | |

| User guide | shhark® Aluminum Group 2 Pump Technical Information | Japanese | Japan | 27 Nov, 2024 | 7.0 MB | |

| User guide | shhark® Aluminum Group 2 Pump Technical Information | English | Multiple | 28 Apr, 2023 | 3.8 MB | |

| Data sheet | shhark® and Compact Multiple Pump Data Sheet | English | Multiple | 25 Jan, 2023 | 1.1 MB |

Product range

Related applications

-

if (isSmallPicture) {

Construction

ConstructionSpace is limited on construction sites, and there are people working everywhere. Contractors need machines that can safely maneuver in a tight spot. At the same time they still need to be powerful enough to get the job done. At Danfoss, we deliver the components, software, and controls that enable your machines to run safely, efficiently and effectively.

-

if (isSmallPicture) {

Crane and material handling

Crane and material handlingCranes and other large handling machines are required to operate within very specific load ranges. Danfoss provides pressure transmitters that supply load limiting systems with crucial data, safeguarding your equipment, your load, and your operator.

-

if (isSmallPicture) {

Forestry

ForestryRough, sloping terrain and cramped working conditions call for robust and reliable forestry machines. We make sure you can manage everything from cutting trees and transport to preparing the forest floor for replanting. We have the smart hydraulic solutions your machines need for precise and efficient forestry operations.

-

if (isSmallPicture) {

Heavy machinery

Heavy machineryThink about the heaviest challenges in the open mining, road building and construction industry. Tasks such as cutting through rock or the Arctic permafrost; compacting thick layers of hot asphalt. As well as lifting huge, prefabricated wall panels into place.

-

if (isSmallPicture) {

Lawn and turf

Lawn and turfLawn and turf machines must adapt to their surroundings and the season – becoming sweepers or snow blowers as required. At Danfoss, we make hydraulic solutions to provide that flexibility and ensure safe and efficient operation.

-

if (isSmallPicture) {

Road building

Road buildingAdvanced hydraulic systems from Danfoss deliver the machine performance that ensures road builders can meet their deadlines.

Related solutions

-

if (isSmallPicture) {

All-wheel steering

All-wheel steeringAll-wheel steering is one example of how Danfoss is at the forefront of machine versatility. This helps customers getting the most out of their equipment. Electrohydraulic steering system enables operators to manually adjust the steering mode, allowing them to best match machine performance to the task at hand.

-

if (isSmallPicture) {

Steering

SteeringAs the global market leader in steering components and systems, Danfoss equips everything from small lawn machines to the largest dump trucks.

-

if (isSmallPicture) {

Thermal management

Thermal managementDanfoss is here to help. With our complete fan drive solution, Danfoss is able to help you maximize available engine power. As well as, decrease fuel costs and increase operator productivity.

-

if (isSmallPicture) {

Work functions

Work functionsOur total systems approach integrates advanced Danfoss hardware and software to deliver exceptional work function control.

Related products

-

if (isSmallPicture) {

Lumi gear pumps

Lumi gear pumpsA solid product line for standard applications with unique design featuring cast iron flange and end cover for optimum reliability. Suitable for wide variety of applications that demands standard pump performance.

-

if (isSmallPicture) {

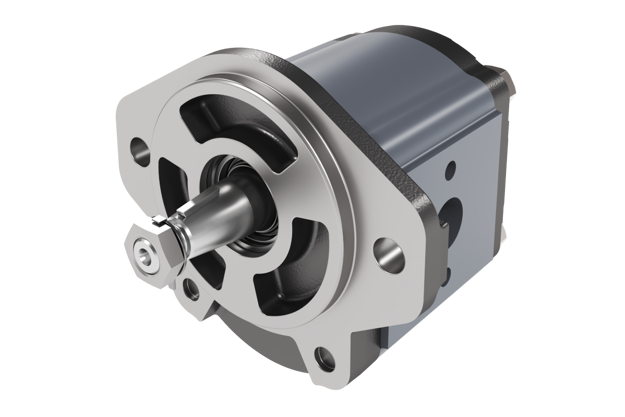

shhark® AL low noise gear pump Gr 2

shhark® AL low noise gear pump Gr 2shhark® is our latest evolutionary low noise patented gear pump technology. An outstanding performance guaranteed throughout the whole life of the pump.

-

if (isSmallPicture) {

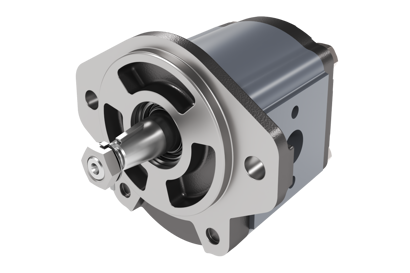

Shhark® aluminum low noise gear pump Gr 2

Shhark® aluminum low noise gear pump Gr 2Shhark® is our latest evolutionary low noise patented gear pump technology. An outstanding performance guaranteed throughout the whole life of the pump.

-

if (isSmallPicture) {

Rugid gear pumps

Rugid gear pumpsOur Rugid gear pumps are 20% smaller than conventional gear products, and give great power density in a small package. Typical applications are skid steer loaders and heavy-duty machines.

Resources

Visit PowerSource

Visit PowerSource to view product specifications, literature and helpful tools like product configurators, 2D/3D models, Cross reference, crimp specs and many more.