Villa stations and district heating stations covering all Indirect heating applications

An indirect substation is used when district heating network conditions, such as pressure and temperature, do not allow direct connection. When a substation is connected indirectly, a heat exchanger provides energy-efficient heat transfer. It also ensures that the primary network supply side and the secondary building installation side remain safely separated.

In this way, the building application works regardless of pressure or temperature variations in the district heating network (hydronic balancing) and is safe from pipe breaks or leaks.

Features and benefits

Integrated components ensure safe operation, increases durability and minimize whole life costs

Benefit from optimized heat transfer and system control performance

Compact design - Minimum space required for installation

Thermostatic or electronic control of heating temperature

Operates independently of differential pressure and flow temperature

Low energy loss

Wide capacity range – up to 20 MW

Deep-dive into the new VXe villa substation series

This animation takes you inside each substation in the series and shows how the Danfoss-engineered core components work together to improve energy efficiency and substation performance.

Product range

Find the right villa station for your indirect heating application

Check out our easy and simple product overview and find exactly the villa station that fits your application requirements.

Find the right district heating stations for your indirect heating application

Check out our easy and simple product overview and find exactly the district heating station that fits your application requirements.

Product highlight

-

if (isSmallPicture) {

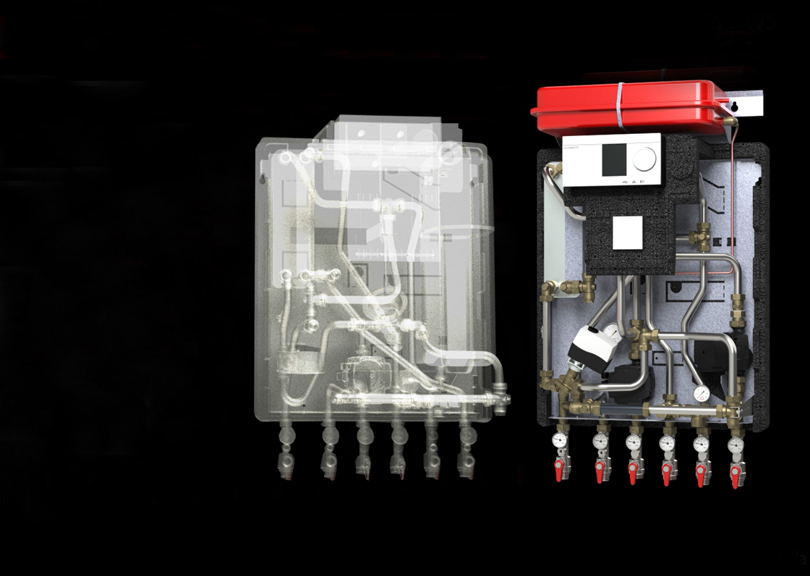

DSP MOD@ substation

DSP MOD@ substationDSP stands for ‘Danfoss Substation Prefabricated’, highlighting the fact that you get a substation that is easy to install and that complies with 90% of the typical district heating network technical connection requirements. MOD@ stands for ‘modular and digital’, meaning you get a substation that’s flexible, easy to configure and works seamlessly with our digital district heating network product portfolio.

Tools and apps

Danfoss Heat Selector

The Danfoss Heat Selector is a best-in-class online selection tool that optimizes planning process for heating application experts.