Minimize unexpected downtime and increase your efficiency with faster response

With DrivePro® Remote Monitoring, you will have a system that provides online information available for monitoring in real time, which makes is possible for you to react much faster to incidents where an AC drive is involved. This is possible due to the built-in alerting system that generates faults and warnings. Because you are immediately made aware of potential drive problems – even if you are not on-site – you can react equally quickly to avoid unexpected failures, minimize costly downtime, and eliminate disruption of your operations.

For expert users of this service, DrivePro® Remote Monitoring provides unrestricted access to all the data that has been collected from your drives. This is very useful for identifying adverse trends such as a slow increase in motor current over time, which may point to wear or lack of lubrication in the driven device.

DrivePro® Remote Monitoring also offers centralized backup and restore capabilities for all AC drives connected under this setup, as well as full visibility of and access to the entire connected drive asset, including drive firmware versions.

How it works

Features and benefits

Alerts in case of drive fault

- Quick response to issues

Key drive data and parameters stored in the cloud

- Fast access to essential information

Fault data available in the cloud

- Rapid, accurate resolution

Accurate, real-time measurements and analytics KPIs from the drives

- Ability to check the status and make the right decisions

AC drive parameters are backed up safely in a centralized location

- Simple recovery in case of AC drive failure or exchange

Predictive maintenance schemes

- Prevent failures before they occur

Troubleshooting by Danfoss engineers

- DrivePro® Remote Monitoring experts will assist you in finding the best solution for your application needs and to maximize your uptime

- Confidence of support with Danfoss or a local DrivePro® service partner

FAQ

Documents

| Type | Name | Language | Valid for | Updated | Download | File type |

|---|---|---|---|---|---|---|

| Fact sheet | DrivePro Remote Monitoring | English | Multiple | 14 Oct, 2024 | 1.0 MB | |

| Fact sheet | DrivePro Remote Monitoring - Brazil Portuguese | Portuguese | Multiple | 17 Oct, 2024 | 573.0 KB | |

| Fact sheet | DrivePro Remote Monitoring - Chinese | Chinese (CN) | Multiple | 17 Oct, 2024 | 633.0 KB | |

| Fact sheet | DrivePro Remote Monitoring - Czech | Czech | Multiple | 04 Apr, 2022 | 933.9 KB | |

| Fact sheet | DrivePro Remote Monitoring - Danish | Danish | Multiple | 04 Apr, 2022 | 934.0 KB | |

| Fact sheet | DrivePro Remote Monitoring - Dutch | Dutch, Flemish | Multiple | 04 Apr, 2022 | 935.2 KB | |

| Fact sheet | DrivePro Remote Monitoring - French | French | Multiple | 02 Dec, 2024 | 580.2 KB | |

| Fact sheet | DrivePro Remote Monitoring - German | German | Multiple | 17 Oct, 2024 | 593.4 KB | |

| Fact sheet | DrivePro Remote Monitoring - Italian | Italian | Multiple | 17 Oct, 2024 | 572.1 KB | |

| Fact sheet | DrivePro Remote Monitoring - Polish | Polish | Multiple | 04 Apr, 2022 | 934.5 KB | |

| Fact sheet | DrivePro Remote Monitoring - Russian | Russian | Multiple | 04 Apr, 2022 | 939.3 KB | |

| Fact sheet | DrivePro Remote Monitoring - Spanish | Spanish, Castilian | Multiple | 17 Oct, 2024 | 580.9 KB | |

| Fact sheet | DrivePro Remote Monitoring - US English | English | United States | 14 Oct, 2024 | 1.0 MB |

Case stories

-

if (isSmallPicture) {

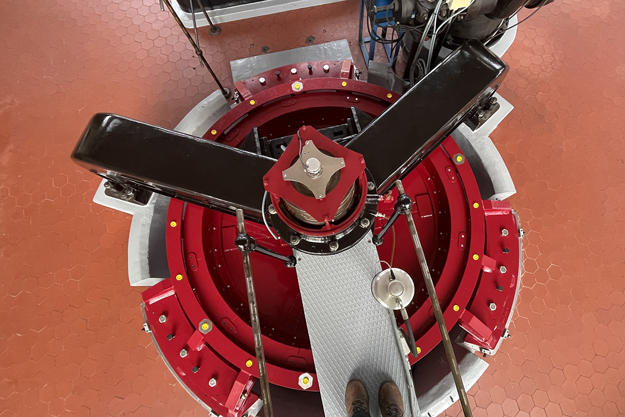

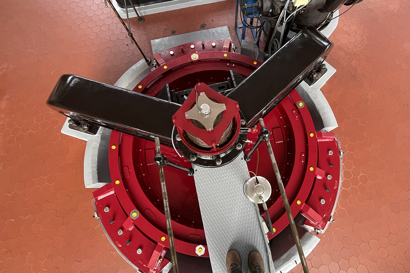

Unlocking efficiency with a drive retrofit at a Czech hydropower plant

Unlocking efficiency with a drive retrofit at a Czech hydropower plantCZECHIA: When 80-year-old gears were replaced by variable speed control at the Albrechtice hydropower plant, power production increased by 10%.

-

if (isSmallPicture) {

DrivePro® reduces cost, downtime, and failure rate for Dahe Paper Group

DrivePro® reduces cost, downtime, and failure rate for Dahe Paper GroupCHINA: Thanks to several Danfoss DrivePro® services, Dahe Paper Group, a state-owned paper mill company in China, has reduced its costs, downtime, and failure rate.

-

if (isSmallPicture) {

Wind tunnel achieves 99.5% uptime with Danfoss DrivePro®

Wind tunnel achieves 99.5% uptime with Danfoss DrivePro®Belgium: Thanks to Danfoss DrivePro® services, LuxFly has achieved 99,5% uptime in Europe’s largest vertical wind tunnel that is used for skydiving.

-

if (isSmallPicture) {

How did this smart factory reach carbon-neutral?

How did this smart factory reach carbon-neutral?POLAND: The new Danfoss production hall in Grodzisk Mazowiecki has reached carbon-neutrality, thanks to full electrification, energy-saving solutions such as Danfoss drives, and energy from renewable sources.

-

if (isSmallPicture) {

DrivePro® Lifecycle Services secure maximum uptime for Rothes CoRDe

DrivePro® Lifecycle Services secure maximum uptime for Rothes CoRDeSCOTLAND: The Rothes CoRDe plant, a biomass-fired combined heat and power (CHP) plant, ensured maximum uptime thanks to several DrivePro® Lifecycle Services.

-

if (isSmallPicture) {

Refrigeration systems preserve apple quality using VSDs with integrated condition monitoring and DrivePro Remote Monitoring service

Refrigeration systems preserve apple quality using VSDs with integrated condition monitoring and DrivePro Remote Monitoring serviceITALY: At Rivoira Group, VLT® drives with built-in condition-based monitoring help preserve fruit perfectly by ensuring utterly reliable refrigeration.