Complete fan drive solutions

Maximize available engine power, decrease fuel costs, and increase operator productivity with our complete fan drive solutions.

Optimize fan drive solutions with the Reverse Displacement Motor (RDM) and the new Series 45 Fan Drive Control (FDC). The RDM is a breakthrough in technological innovation and engineering. The heart of the new technology is an integrated shift valve. This, when used in a fan drive application, allows for cost savings and improved fan drive efficiency. The Series 45 FDC is available on K2, F, and J frame sizes. It is the industry best for weight, package, and serviceability. The lower minimum system pressures allowed by the fan drive control results in slower minimum fan speeds. This improves fan drive system efficiency and offers benefits for low cooling requirement conditions.

Our H1 family of closed-circuit pumps and motors offer fan drive system solutions for high-power applications. The variable displacement of H1 pumps allows to decouple fan and engine speed enabling precision control of cooling by optimizing fan operation. At the same time keeping the system performing at its best while maximizing efficiency. In addition, the commanded neutral is capable of outputting zero fan speed for advanced applications and greater flexibility. H1 Fan Drive Control (FDC) is optimized for increased horse power operations. Its open wire detection enables fail to full cooling for safe vehicle operation. Both H1 and FDC are fully supported by Plus+1® GUIDE compliance blocks. Which is making it easier to implement a field proven and reliable fan drive system.

Based on your unique cooling needs, we can work with you to design several different open circuit and closed-circuit fan drive systems for a variety of applications including tractors, combines, and harvesters. All Danfoss configurations also involve the use of PLUS+1® microcontrollers for precise and efficient control.

Addressing your challenges

Your machines can help make the world a better place — and Danfoss engineers can use their systems knowledge and expertise to help make your machines strong competitors in the marketplace.

Related products

-

if (isSmallPicture) {

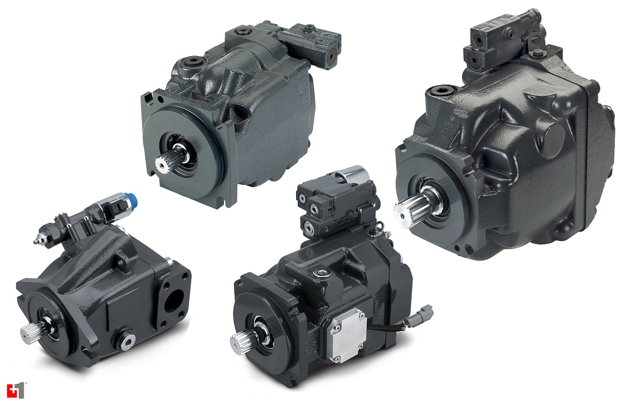

Series 45 open circuit axial piston pumps

Series 45 open circuit axial piston pumpsSeries 45 family pumps are a high-performing and flexible option for new machine applications needing variable displacement open-circuit flow. With displacements from 25cc to 147cc [1.53 in3 to 8.97 in3], speeds up to 3,600 rpm, and pressures up to 310 bar [4,495 psi], these pumps are designed to exceed the demanding requirements of the mobile equipment marketplace. Each frame within the Series 45 family is uniquely designed to optimize performance, size, and cost. Series 45 pumps are produced in North America, Europe, and Asia.

-

if (isSmallPicture) {

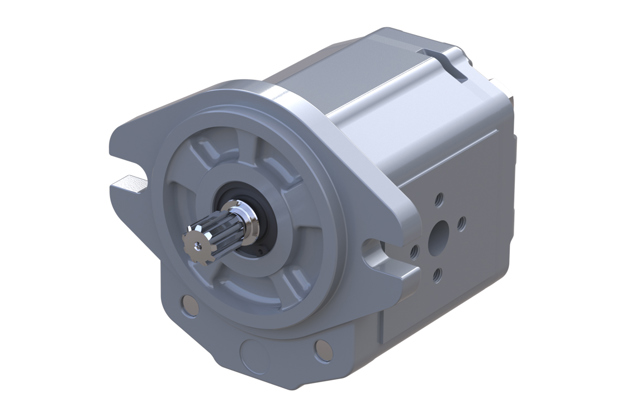

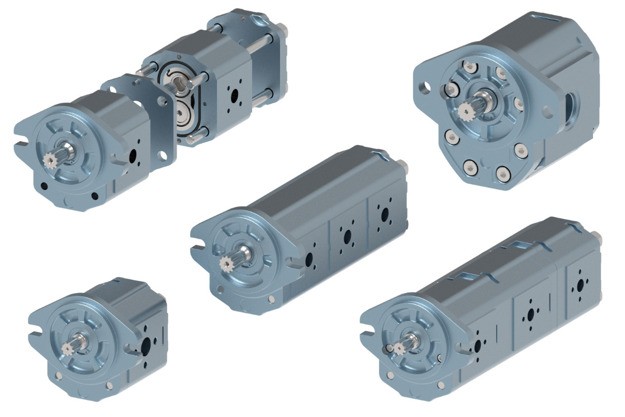

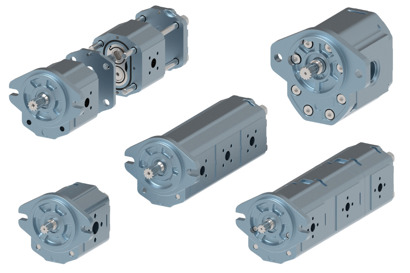

Low noise aluminum gear pumps

Low noise aluminum gear pumpsOur latest low noise patented gear pump technology. An outstanding performance guaranteed throughout the whole life of the pump.

-

if (isSmallPicture) {

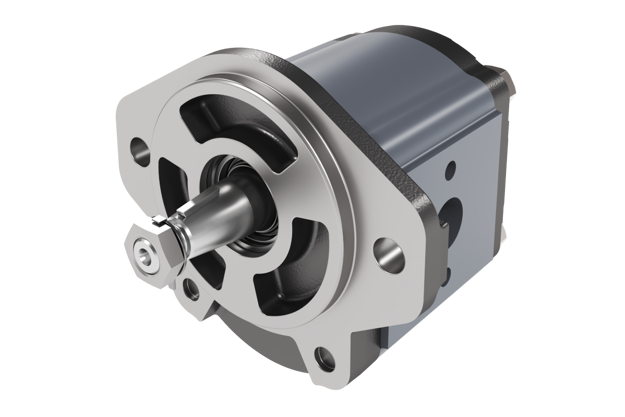

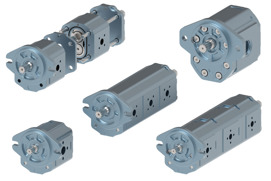

Lumi gear pumps

Lumi gear pumpsA solid product line for standard applications with unique design featuring cast iron flange and end cover for optimum reliability. Suitable for wide variety of applications that demands standard pump performance.

-

if (isSmallPicture) {

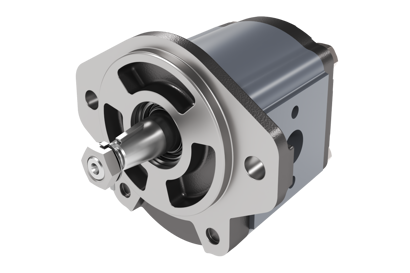

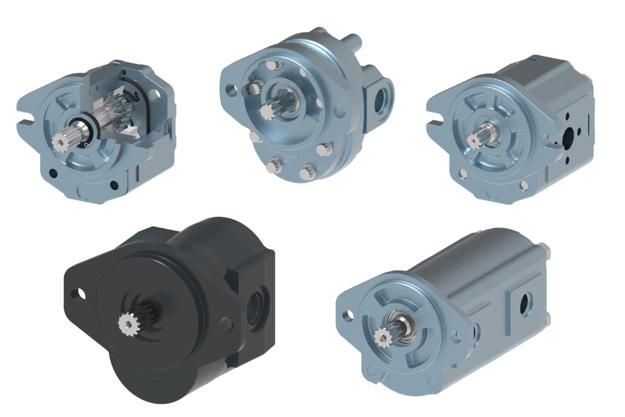

Gear pumps

Gear pumpsWe engineer, manufacture and supply gear pumps of superior quality. We work closely with our customers around the world. Combining long-standing tradition and relentless innovation, to deliver optimal gear products.

-

if (isSmallPicture) {

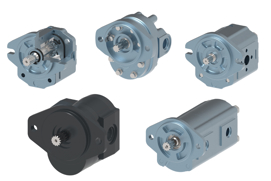

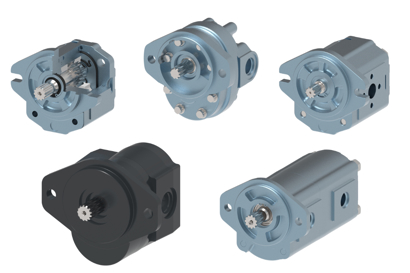

GearMe gear pumps

GearMe gear pumpsOur gear pumps are robust and reliable. They are the ideal choice for a wide range of applications. From small to medium and large off-highway vehicles, as well as for industrial applications. Low noise gear pumps are also available. They are the ideal solution for steering applications in cab-equipped mobile machines and for electric/hybrid machines.

Related solutions

-

if (isSmallPicture) {

Thermal management

Thermal managementDanfoss is here to help. With our complete fan drive solution, Danfoss is able to help you maximize available engine power. As well as, decrease fuel costs and increase operator productivity.

Contact us

For further information, please contact us.