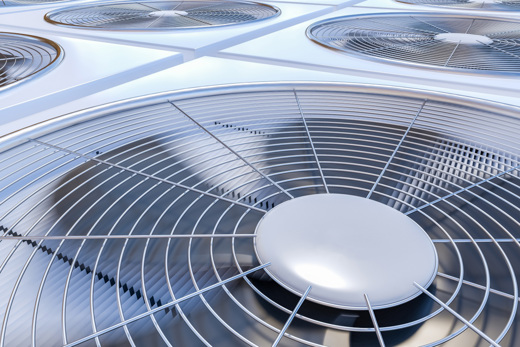

Win energy savings with variable speed fan control

As energy becomes increasingly expensive, variable speed control of electrical motors has proven to be one of the most effective cost-reducing measures available. For example, by reducing the average speed of the fan motor from 100% to 80%, 50% energy is saved. Reducing the average speed by 50% increases the savings to 80%.

In addition to saving energy, fans benefit from dedicated drive features such as the ‘skip resonance’ function. This improves comfort levels by avoiding frequencies that create noise and damage.

Reliable fan control can maintain specific air pressure and ensures a consistently hygienic environment for food and beverage operations. Condensor fan control gives a range of advantages including reduced charge of refrigerant, less build-up of dirt on the condenser, and the ability to run a floating setpoint for energy savings.

For hygienic environments, Danfoss drives are available with enclosures designed to resist daily washdown.

Find the right drive for your application, by answering a few simple questions. Start here: Danfoss DriveFinder

See how Arla Foods Ingredients saves energy on fan and pump applications

VLT® drives ensure maximum uptime, high precision, and cut Arla’s energy demand – also benefiting customers.

Products

-

if (isSmallPicture) {

VLT® AutomationDrive FC 301 / FC 302

VLT® AutomationDrive FC 301 / FC 302The VLT® AutomationDrive FC 301 / FC 302 is designed for variable speed control of all asynchronous motors and permanent magnet motors. It comes in a standard version (FC 301) and an advanced high dynamic version (FC 302) with additional functionalities.

-

if (isSmallPicture) {

VLT® HVAC Drive FC 102

VLT® HVAC Drive FC 102This tough and savvy FC102 drive enhances pump and fan applications in building management systems, and runs outdoors in most climates.

-

if (isSmallPicture) {

iC7-Automation

iC7-AutomationWhatever the environment, the iC7-Automation delivers the reliability and performance you need. With connectivity, security and intelligence, this drive lets you take advantage of the latest in Industrial IoT.

Case stories

-

if (isSmallPicture) {

Carlsberg brewery drives down energy consumption

Carlsberg brewery drives down energy consumptionPOLAND: For more than a decade, Danfoss drives have reduced the power consumption at Carlsberg’s Okocim Brewery. The brewery uses less water and has lowered its emissions, too.

-

if (isSmallPicture) {

VLT® Midi Drive optimizes efficiency in Brazilian biscuit factory

VLT® Midi Drive optimizes efficiency in Brazilian biscuit factoryOriginal equipment manufacturer, Ariete, delivers quality and a competitive edge using the same drive for different applications.

-

if (isSmallPicture) {

Danfoss DrivePro® services make success extra sweet

Danfoss DrivePro® services make success extra sweetINDIA: The Rajarambapu co-operative sugar factory has used Danfoss drives for nearly 15 years, saving them energy and protecting equipment.

-

if (isSmallPicture) {

Up to 15% energy savings for Arla

Up to 15% energy savings for ArlaThe highest quality lactose pays off – also for the end user

-

if (isSmallPicture) {

VLT drives save up to 15% energy consumption at Arla Food Ingredients Group

VLT drives save up to 15% energy consumption at Arla Food Ingredients GroupDENMARK: On Arla Foods Ingredients manufacturing site more than 600 VLT® AutomationDrive units are controlling hundreds of pumps, fans, and evaporators to save energy and reduce costs.

-

if (isSmallPicture) {

Gostol-Gopan’s energy consumption halved

Gostol-Gopan’s energy consumption halvedThe VLT® AutomationDrive FC 302 optimizes baking time and decreases centrifugal fan speed by 20% to halve energy consumption.

Contact us

For further information please contact us