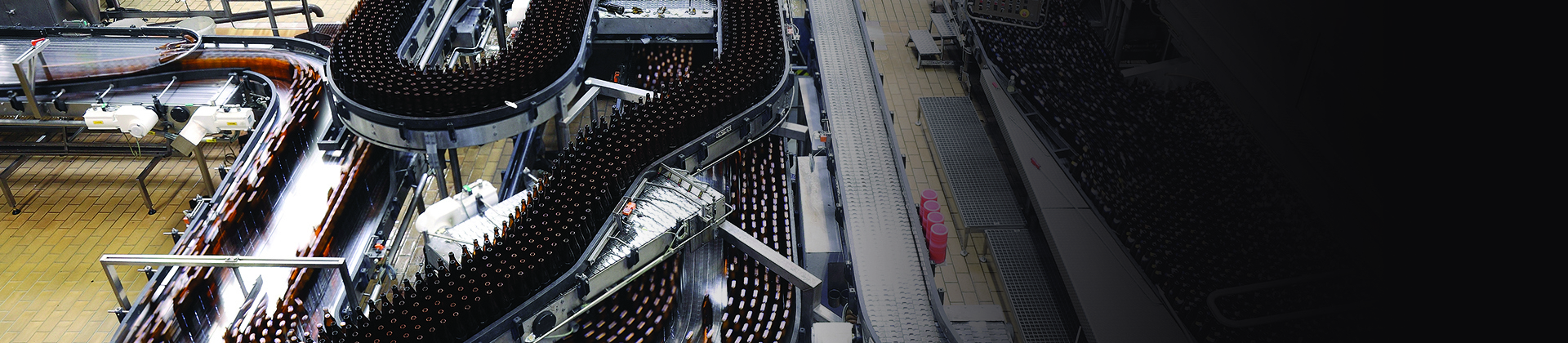

Maximize conveyor uptime

Ensure maximized uptime and the lowest cost of ownership for conveyors in dry, wet, or aseptic areas. Danfoss solutions ensure high energy efficiency whilst providing optimized motor control, improved quality and product consistency, minimized waste and optimized filling and packaging areas.

For highly sensitive product lines, such as conveyors for still bottled water and alcohol-free beer or new materials for packaging and bottles, Danfoss is unique in offering IPA compliant solutions for use in hygiene-critical sub-systems.

Examples of conveyor optimization using drives

Find the right drive for your application, by answering a few simple questions. Start here: Danfoss DriveFinder

Discover how to maximize uptime with the Danfoss FlexConcept® system

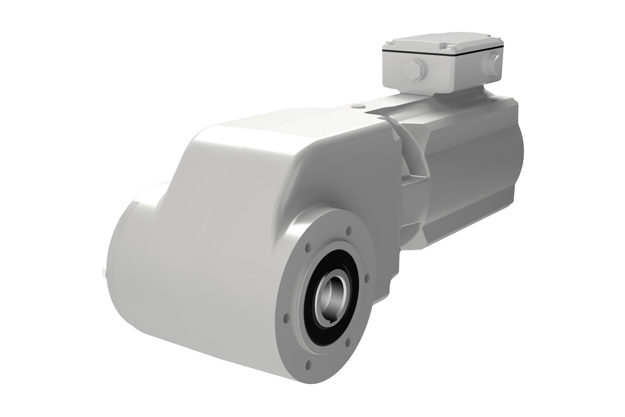

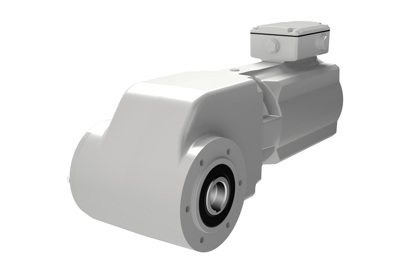

Danfoss FlexConcept® combines modern motor technology with the most advanced inverter drives. This flexible unified drive system offers cost savings via high efficiency, robust reliability and variant reduction.

Reduce spare parts stock

The Danfoss FlexConcept® system simplifies project planning, installation, commissioning and maintenance, especially for conveyor systems. System variants can be reduced by up to 70% so users benefit from maximum flexibility with a minimum number of modules. The system comprises only 3 gear motor variants to optimize your spare parts stock. Motors and drives in the Danfoss FlexConcept® system offer a unified operating concept and standardized functionality regardless of whether the system is implemented with a centralized or decentralized structure.

FAQ

Products

-

if (isSmallPicture) {

iC2-Micro

iC2-MicroThis next-generation micro drive gives you great cost effectiveness, durable reliability, and user-friendly commissioning and operation, all in a compact package.

-

if (isSmallPicture) {

VLT® Midi Drive FC 280

VLT® Midi Drive FC 280FC280 provides precise and efficient motor control for machine builders in the food and beverage, material handling and processing industries.

-

if (isSmallPicture) {

iC7-Automation

iC7-AutomationWhatever the environment, the iC7-Automation delivers the reliability and performance you need. With connectivity, security and intelligence, this drive lets you take advantage of the latest in Industrial IoT.

-

if (isSmallPicture) {

VLT® OneGearDrive®

VLT® OneGearDrive®A highly efficient combination of a permanent magnet motor and optimized bevel gearing.

-

if (isSmallPicture) {

VLT® Decentral Drive FCD 302

VLT® Decentral Drive FCD 302Thanks to its rugged design, the FCD302 drive can be mounted close to motors in demanding applications.

Case stories

-

if (isSmallPicture) {

Terra Production boosts capacity by 70% with Danfoss iC7-Automation

Terra Production boosts capacity by 70% with Danfoss iC7-AutomationSERBIA: With a new filling line driven by Danfoss iC7 drives, Terra Production has boosted its annual capacity by 70%. Early results demonstrate that Terra Production is now better positioned to meet growing customer demand, reduce energy consumption, and ensure sustainable production.

-

if (isSmallPicture) {

iC7-Automation drives König’s automatic crate sorter at DGL

iC7-Automation drives König’s automatic crate sorter at DGLKönig and Danfoss smoothly integrated iC7-Automation into DGL sorting machines for returned bottle crates. The highly efficient system sorts 3,600 crates hourly.

-

if (isSmallPicture) {

Future-proof energy efficiency at AB InBev Hoegaarden® brewery

Future-proof energy efficiency at AB InBev Hoegaarden® breweryChallenged by aging machinery and no time for downtime, AB InBev Hoegaarden® chose Danfoss iC7-Automation and VLT® OneGearDrive®—for high energy efficiency.

-

if (isSmallPicture) {

Effortless control: Kohberg Bakery thrives with iC7-Automation

Effortless control: Kohberg Bakery thrives with iC7-AutomationDENMARK: Kohberg Bakery upgraded its conveyor line for bread rolls to implement full control with built-in sensors and easy scalability for future adaptability.

-

if (isSmallPicture) {

First mover controls beverage conveyor systems with iC7-Automation

First mover controls beverage conveyor systems with iC7-AutomationBELGIUM: Legendre Conveyors has built up great trust in Danfoss over many years of conveyor design using VLT® drives. Now they progress to the new iC7 series.

-

if (isSmallPicture) {

Maximizing uptime for high-volume bottle filling

Maximizing uptime for high-volume bottle fillingNORTH MACEDONIA: To meet new standards for uptime, flexibility, and energy efficiency, Pivara Skopje’s RGB line needed modernization. The ideal VSDs? VLT® FlexConcept®.