Decarbonization comes down to numbers. We help you reach yours.

Few industries hold more potential for decarbonization than food & beverage due to its enormous fleets of equipmet. Reducing the energy consumption and carbon emission of every single freezer, fridge, bottle cooler, or glass door merchandiser is therefore key to achieving a more energy efficient and sustainable fleet.

But the large number of units also means that even small changes can have a huge impact toward your decarbonization goals. That is why we leverage our strong application expertise, complete portfolio, and proven results to help you reach your number — whatever it is.

Get in touch to uncover the potential in decarbonizing your cooler fleet.

New cooler design cuts energy use by 30%

Partnering with a leading food and beverage manufacturer, we redesigned a bottle cooler by replacing its key components to improve performance while reducing energy usage and carbon footprint.

A strong partner for your decarbonization journey

We know. When it comes to sustainable refrigeration solutions, you need a partner who will not only help you uncover your possibilities – but also unleash their full potential.

Why choose Danfoss':

We offer unmatched technical expertise from 90+ years of working with refrigeration

Our suite of solutions improve the performance and reduce the energy consumption of your cooling equipment fleet

We provide the application knowledge base to fast-track design and time-to-market

— including five Application Development Centers around the globe

We partner with other players in the climate space to develop innovative solutions and drive a science-based regulatory environment

Our organization has the global wingspan and innovation engine to accelerate your decarbonization journey

Reach out to discuss partnering with us.

Reducing energy consumption in cooler fleets

While the need for proven results in sustainable refrigeration is clear, how to reach them might not be. We’ve summed up three simple steps for optimizing energy efficiency in your glass door merchandiser, commercial fridge, or freezer.

Highlighted products

-

if (isSmallPicture) {

Thermostatic expansion valves

Thermostatic expansion valvesThermostatic expansion valves (TXV) are available as parts programs, i.e. with separate valve body and orifice assemblies, or as complete valves (fixed orifice). The category also contains thermostatic injection valves.

-

if (isSmallPicture) {

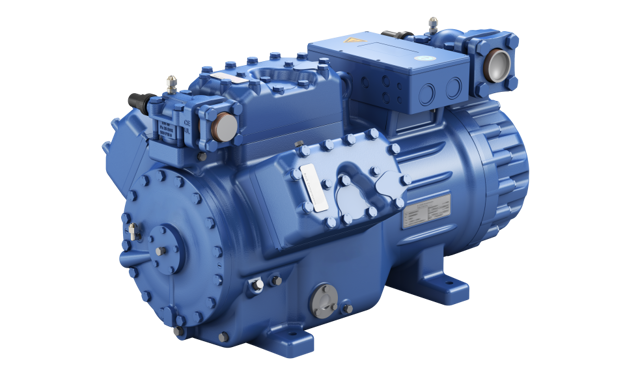

Semi-hermetic reciprocating compressors

Semi-hermetic reciprocating compressorsHigh-quality, durable, and sustainable semi-hermetic compressors. Our diverse product portfolio includes air and gas cooled models, low GWP refrigerants, and more. Built for sustainability, efficiency, and reliability. Explore our compressors for refrigeration and air conditioning needs.

-

if (isSmallPicture) {

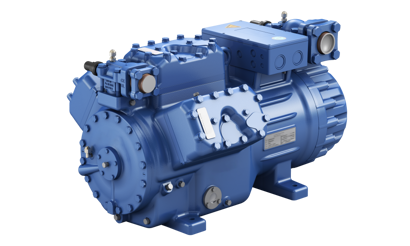

Open-type reciprocating compressors

Open-type reciprocating compressorsBOCK®'s open-type compressors for your HVAC-R needs, offering reliability and efficiency. Explore the F-series compressors designed for marine and stationary refrigeration, ensuring performance, ease of use, and extended maintenance intervals. Trust in BOCK® for cost-effective, efficient, and durable solutions.

-

if (isSmallPicture) {

Light commercial compressors (DL, FR, GS, NL, PL, SC, TL)

Light commercial compressors (DL, FR, GS, NL, PL, SC, TL)Light commercial reciprocating compressors for low, medium and high temperatures.

-

if (isSmallPicture) {

Refrigeration scroll compressors

Refrigeration scroll compressorsWith MLZ and LLZ, take advantage of a scroll compressor for refrigeration that is efficient by design. The MLZ and LLZ series are purpose-engineered for applications at medium and low temperatures.

-

if (isSmallPicture) {

Compressors for refrigeration

Compressors for refrigerationDanfoss focuses on providing energy efficient, sustainable and smart refrigeration compressors for a varied range of commercial applications such as cold rooms, display windows, ice making machines, glass door merchandizers, process cooling etc. Their qualification with lower GWP refrigerants make them compliant with refrigerant regulations such as F-Gas in Europe.

Cutting Carbon Emissions in Valve Production

In a step towards sustainability, Danfoss has significantly reduced carbon emissions by 74% – compared to 2019 – in the production of thermostatic expansion valves.

Maximize energy efficiency with Optyma™

Reduce energy consumption with Optyma™ bare condensing units—designed for superior efficiency and performance in commercial refrigeration.

Contact us

Small changes. Big impact.

On the road to global decarbonization, the phrase ‘Every little bit helps’ rings especially true when it comes to how to decarbonize refrigeration equipment. Because with an estimated 60 mill. glass door merchandiser units currently in operation worldwide, even the smallest improvement of their performance and energy efficiency will result in a significant reduction of CO₂ emissions.

But you might be wondering how much impact optimizing a cooling fleet will actually have on the bigger picture and our environment?

Decarbonization that counts

Consider these numbers: the 30% energy reduction we achieved with our redesigned bottle cooler equals using 216kWh less/year. Danfoss can help decarbonize a sustained number of 2 mill. glass door merchandisers* totaling an energy reduction of 432 mill. kWh. This translates into emitting 200,000 tons less of CO₂e** — the equivalent of saving almost 1.4% of Denmark’s yearly energy generation***. Read that again.

In other words, by optimizing the performance of your refrigeration units, you not only increase food and beverage sustainability but also contribute directly to global decarbonization efforts and mitigating climate change.

From possibility to reality

There’s a reason decarbonization is considered a journey but we’re here to help you every step of the way by delivering both the expertise and technology you need for sustainable refrigeration. So, join us in turning your possibilities into reality – and let’s reach your number together.

* Number of units in continuous operation after a ramp-up period of ten years. Danfoss can help decarbonize 200,000 units per year. Average unit lifetime is defined as 10 years.

** Estimate based on avg. global emission factor of electrical generation (464g/kwh) (IEA – Global emission factors report 2021)

*** Denmark generated 32TWh in 2022 https://www.iea.org/countries/denmark/electricity