High-quality treats, every time

For businesses in the food and beverage industry, commercial ice cream machines and frozen beverage machines are essential for delivering high-quality, consistent treats. Danfoss solutions ensure energy efficiency, food safety, and precision temperature control—helping your commercial ice cream maker or commercial frozen beverage machine operate reliably even in demanding environments.

Commercial soft ice cream machines: reliability and consistency you can trust

Commercial ice cream machines are designed to produce gelato, frozen yogurt, sorbet, and soft-serve ice cream for cafés, restaurants, bakeries, and convenience stores. Operating efficiently in high-ambient temperatures and small spaces, these machines require precision-engineered components to maintain performance.

Danfoss offers a complete portfolio of compact, durable compressors, refrigerant solutions, and electronic controls tailored for commercial ice cream machines. Our solutions:

- Enhance energy efficiency – Reduce operational costs while maintaining high output.

- Ensure food safety – Maintain precise temperature control to meet HACCP principles.

- Optimize performance – Deliver consistent texture and flavor in every batch.

No matter the conditions, Danfoss helps businesses keep their commercial ice cream makers running smoothly, ensuring customer satisfaction every time.

Commercial frozen beverage dispensers: precision and quality for every sip

From convenience stores and cafes to quick-service restaurants and petrol stations, commercial frozen beverage machines play a vital role in serving refreshing frozen drinks. These machines must maintain consistent temperatures, superior quality, and reliable performance to meet customer expectations. Danfoss solutions provide:

- Precision temperature management – Ensuring perfect drink texture in every serving.

- Stainless steel durability – Designed for long-lasting, high-capacity operation.

- Energy-saving features – Reduce operational and maintenance costs.

- Refrigerant compatibility – Works with HFC (A1 and A2L), and natural refrigerants like hydrocarbons (HC) for a future-proof system.

With Danfoss-powered commercial frozen beverage dispensers, businesses can minimize downtime, maximize efficiency, and deliver high-quality frozen drinks with every pour.

Features and benefits

Superior temperature control

Stainless steel products for aggressive environments and the food & beverage industry

Reliable solutions, low operation and maintenance costs

Products suitable for use with all common refrigerants, including natural and A2L refrigerants

Long service life

Behind the perfect scoop

Want to learn more about how commercial ice cream machines function? Explore Danfoss’ advanced refrigeration components that drive efficiency, consistency, and reliability in the ice cream machine and help deliver the perfect scoop every time.

Documents

| Type | Name | Language | Valid for | Updated | Download | File type |

|---|---|---|---|---|---|---|

| Article | Food safety Focus on system performance, reliability and connectivity | English | Multiple | 26 Mar, 2025 | 936.9 KB | |

| Article | Food safety Focus on system performance, reliability and connectivity | Portuguese | Brazil | 22 Oct, 2025 | 1.4 MB | |

| Brochure | Precision cooling for consistent output - Complete refrigeration solutions for commercial ice cream machines | English | Multiple | 19 Aug, 2025 | 818.8 KB | |

| Brochure | Reliable cooling for frozen beverages - Efficient and reliable refrigeration for frozen beverage dispensers | English | Multiple | 18 Aug, 2025 | 861.2 KB |

Related products

-

if (isSmallPicture) {

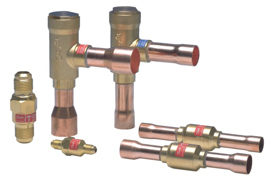

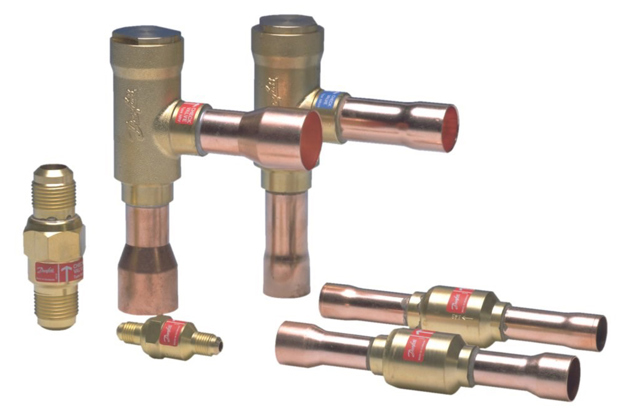

NRV refrigeration check valves

NRV refrigeration check valvesNRV and NRVH can be used in liquid, suction and hot gas lines in refrigeration and air conditioning plants with fluorinated refrigerants. NRV and NRVH can be supplied with flare and solder connections. They are also available with oversize solder connections providing flexibility in the use of check valves.

-

if (isSmallPicture) {

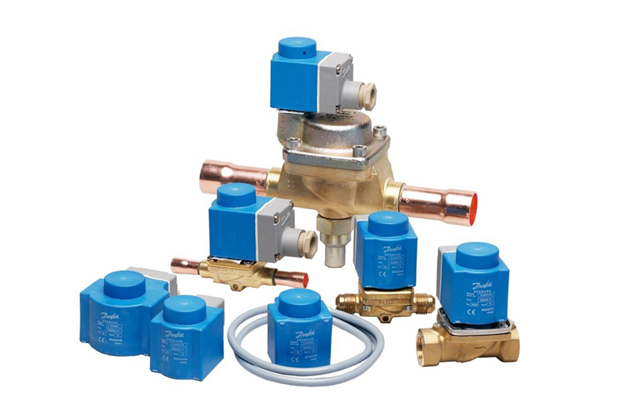

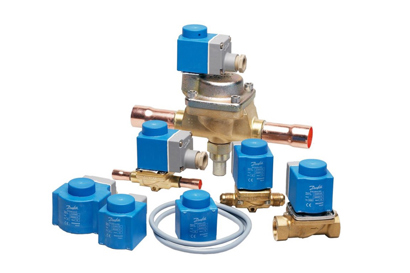

Solenoid valves for HVAC-R

Solenoid valves for HVAC-RSolenoid valves for A/C and commercial refrigeration for fluorinated refrigerants and CO2 (R744). Solenoid valves and coils are normally supplied separately and then assembled without tools, providing optimum flexibility and product availability.

-

if (isSmallPicture) {

Water regulating valves

Water regulating valvesPressure operated water valves are used for regulating the flow of water in refrigeration plants with water-cooled condensers.

-

if (isSmallPicture) {

T2 / TE2 thermostatic expansion valves, exchangeable orifice

T2 / TE2 thermostatic expansion valves, exchangeable orificeT2 / TE2 thermostatic expansion valves are used for liquid injection into evaporators on both refrigeration and air conditioning systems using fluorinated refrigerants. T2 / TE2 is supplied with an interchangeable orifice assembly for easy stocking and service.

-

if (isSmallPicture) {

DML/DCL hermetic filter driers, HFC optimized

DML/DCL hermetic filter driers, HFC optimizedDML hermetic filter driers are optimized for HFC refrigerants and mineral or benzene oils. Compatible with refrigerants R22, R32, R134a, R404A, R410A, R407C, R23, R600, R600a, R744, R1234yf, R1234ze, R407f, R290, R452A, R444B, R449A, R448A and R450A. This product is approved for R290, R600 and R600a by ignition source assessment in accordance to standard EN13463-1.

Case stories

-

if (isSmallPicture) {

Danfoss ADC lab testing helps Haglund improve energy efficiency by 34%

Danfoss ADC lab testing helps Haglund improve energy efficiency by 34%Refrigeration manufacturer Haglund Industri AB wanted to achieve energy efficiency class A. Experts at the Danfoss Application Development Center (ADC) rigorously tested new component packages and reported energy savings up to 34%.

Contact us

For further information, please contact us.