How does Power-to-X support decarbonization?

By converting electricity into other forms of energy, Power-to-X gives us a way to store electricity in new forms. For example, power can be converted via electrolysis into hydrogen gas, which can be stored or used directly. It is a good fuel in pure form or can be combined with other elements to produce E-fuels or chemicals. Power-to-X is an essential element in the green transition because it facilitates storage of energy from renewable sources, for example in the form of green hydrogen from split water.

Enabling you to deliver the most sustainable green hydrogen

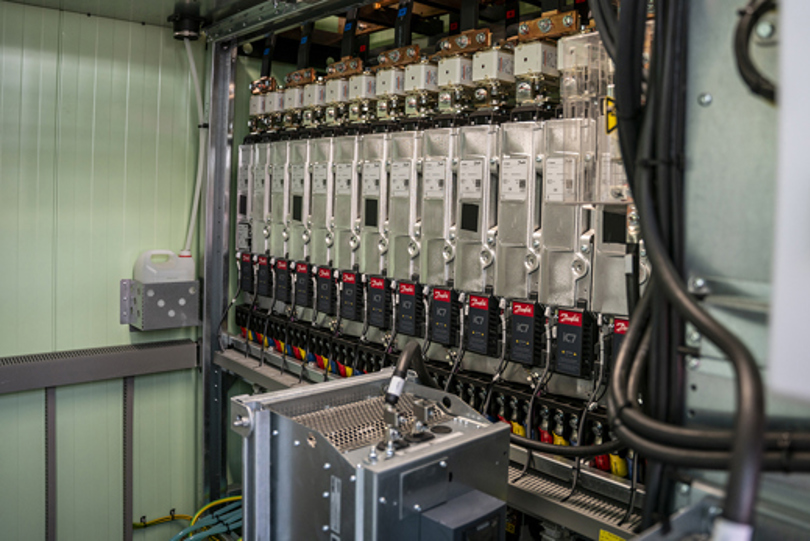

Danfoss technology is a proven basis for reliable electrolyzer systems in these processes. We supply a range of products to support your electrolyzer offering. Danfoss delivers grid-friendly, approved electrolyzer power conversion solutions with impressive energy efficiency.

Low harmonic distortion, adjustable power factor, and other grid-friendly features ensure that the power supply is competitive and grid-compliant. Long experience in power conversion for the electrolyzer, combined with a leading position in the world, means that Danfoss is your ideal partner when investing in the hydrogen production market. Take advantage of our experience to ensure that your electrolyzer system is scalable and economically viable.

Webinar: Towards grid parity

Don’t miss this opportunity to learn more from our experts, as they discuss how to make electrolyzer based green hydrogen production more competitive.

Webinar: Virtual Electrolyzer Design — A Power-to-X qualifier

Learn more about insights on how electrolyzer simulation models can help optimize your Power-to-X value chain. We will deep-dive into what is driving the market right now, and which tools and simulations are the most important to know about.

LinkedIn Live: Relevance of PtX

International hydrogen production companies explain why Power-to-X is incredibly relevant for our decarbonized future, in a live LinkedIn session.

Webinar: Improving performance of the hydrogen electrolyzer

Learn more about the complexities of improving performance in the electrolyzer for hydrogen production, how we can reduce electrolyzer losses, and how to improve grid compliance.

The hydrogen ecosystem - electrolyzer for hydrogen production

Society is being electrified to reduce our carbon footprint. The electric energy from renewable and carbon-free sources is used for direct electrification – and also for indirect electrification.

Direct electrification is the most efficient path to utilize the electric energy – some good examples are electric cars, electric delivery vans, electric short-range ferries – and of course electric industrial processes.

Indirect electrification, green hydrogen and power-to-X are terms which describe how we can electrify the difficult-to-abate sectors like aerospace, deep sea shipping, and heavy industries. Electrolysis using an electrolyzer is the key process in green hydrogen production from renewable electricity and water.

Green hydrogen is a clean fuel which can be used directly in heavy industries like steel and cement plants. It can also fuel heavy road transport – or extend the range of electric ferries, in the form of hydrogen fuel cells.

When compressed, green hydrogen can be transported in pipelines over long distances, just like compressed natural gas. Electrolyzer - produced hydrogen can also be stored in large volumes in underground caverns. Hydrogen gas can also be liquified under high pressure – but the volumetric power density is just one quarter of diesel and it is rather expensive to liquify hydrogen.

Apart from its usefulness in pure form, hydrogen is also the building block for many chemical processes. Hydrogen produced via the electrolyzer can be converted to E-fuels like sustainable aviation fuel, E-kerosene, E-methanol or E-ammonia which can decarbonize many sectors - even with conventional internal combustion engine technology. Hydrogen can also be used as raw material to produce fossil-free plastic and many other synthetical chemicals.

Applications

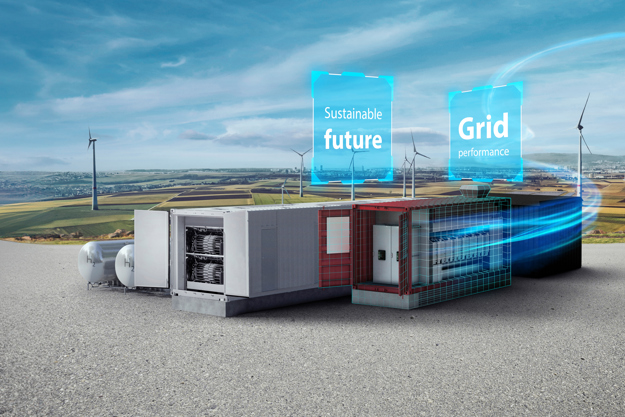

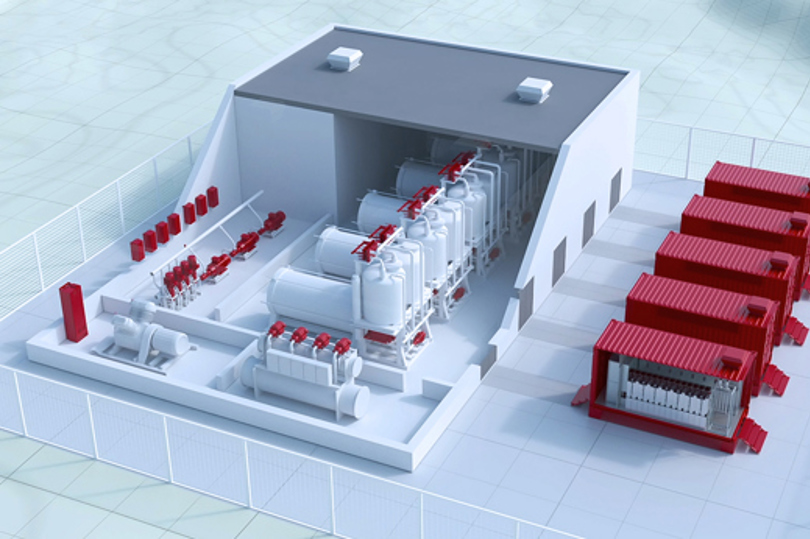

Among the key applications in Power-to-X is the electrolyzer for hydrogen gas production and heat recovery systems. The electrolyzer handles the process where electricity is used to split water molecules to produce hydrogen and oxygen gases. In its pure form, hydrogen can be used to replace fossil fuels in some industries. To e-fuel even more heavy industry, the hydrogen can be synthesized into e-methanol, e-ammonia, or e-diesel. By converting to these sustainable energy sources, we can reduce reliance on fossil fuels.

AC to DC Power supply systems for hydrogen electrolyzers

Since all energy for electrolysis is converted from AC to a variable DC, there is a need for intelligent and reliable power conversion, which Danfoss can provide. To reach the greenest hydrogen gas production, the electrolyzer must also be highly energy efficient. Danfoss power converters offer the highly efficient and flexible power conversion required to run these demanding applications – and they also support many auxiliary applications in power-to-x.

Heat recovery

During the electrolysis process (using an electrolyzer), excess heat is produced as a by-product and can be utilized by other sectors. In Fredericia, Denmark, the HySynergy project is reshaping the energy landscape through a partnership between green hydrogen producer Everfuel and local district heating company TVIS. This project aims to leverage excess heat generated from Everfuel’s green hydrogen production and supply it to local households. The HySynergy project will convert renewable electric energy for Everfuel’s own hydrogen refueling stations, to hydrogen produced for the neighboring Crossbridge Energy refinery, as well as supplying surplus heat to the local district heating system. The project is ideally situated to supply hydrogen for the pipeline planned to connect European countries, in future years.

Our approach

Electrification of energy-consuming sectors plays a vital role as the world is getting to work on a decarbonization of the economy

As a world leader in electrification as well as in heating and cooling solutions, Danfoss has a holistic approach to Power-to-X. Coupled with state-of-the-art co-development facilities and an inherent engineering mindset, we offer knowledge sharing and engineering design to find the best solution to the challenge at hand. With a core focus on energy efficiency and system effectiveness, Danfoss is your expert partner in Power-to-X, both technically and commercially.

Recognized world-wide as a reliable supplier, Danfoss adheres to the highest international quality standards in production and development.

At Danfoss, we help you think beyond the electrolyzer to the system itself. By taking a holistic perspective on the entire ecosystem, we secure energy efficiency and system effectiveness that is both scalable and economically viable. With extensive expertise in Power-to-X systems and electrolysis for producing hydrogen, we tailor the solution to your specific needs. That way you get a plug-and-play system with maximum electrolyzer performance that evolves alongside your operations, at your pace. Danfoss technology has been developed and refined to deliver future-proof, guaranteed performance with many added features to lower risk and ensure a stable electrolyzer operation. You achieve better total economy and peace of mind for operational excellence of each electrolyzer in your electrolysis plant. Danfoss will provide you a grid-friendly, approved solution with impressive energy efficiency. Low harmonics and an adjustable power factor ensure that you have a competitive power supply for your electrolyzer at hand. With long experience in power conversion combined with a leading position in the world, Danfoss is your ideal partner for your investment in the hydrogen market.

Enabling a future powered by electricity

To achieve an electrified world, industry requires solutions that maximize energy efficiency from renewable sources when capacity is high and convert into firm clean energy for use when capacity is low. That requires high efficiency power conversion with low harmonic distortion while ensuring global scalability and cost-effectiveness.

Electrification of energy-consuming sectors is vital for decarbonization

Our ambition is to help you achieve your electrification goals. Because together we can create a sustainable future powered by electricity. As a world leader in electrification as well as in heating and cooling solutions, we here at Danfoss are always thinking holistically on topics such as Power-to-X. Coupled with state-of-the-art co-development facilities and an inherent engineering mindset, our employees are always eager to share their knowledge to find the best solution to the challenge at hand. With a core focus on energy efficiency and system effectiveness, Danfoss is ideally placed as your expert partner in Power-to-X, both technically and commercially.

Recognized world-wide as a reliable supplier, Danfoss adheres to the highest international standards in production and development quality. With Danfoss solutions you get proven competitiveness and reliability, to get your business on target for a decarbonized economy.

Where there is energy, there is opportunity

Coupled with state-of-the-art test facilities and an inherent engineering mindset, our employees are always eager to share their knowledge to find the best solution to the challenge at hand. Together with a core focus on energy efficiency, not only in the products we deliver but also holistically in entire systems, Danfoss is ideally placed as an expert partner in Power-to-X.

Recognized world-wide as a reliable supplier, Danfoss adheres to the highest international standards in production and development quality. One example: our drives for power conversion are produced and developed according to the stringent requirements of the automobile industry.

Support for your pioneering projects

Tap into a wealth of expert application know-how from Danfoss professionals. The Centers of Excellence and Application Development Centers are ready to help you in engineering very specialized or demanding installations, no matter where in the world you are located.

Case stories

-

if (isSmallPicture) {

Revolutionizing green hydrogen production with Danfoss Drives

Revolutionizing green hydrogen production with Danfoss DrivesDENMARK: The Everfuel HySynergy facility produces green hydrogen with the help of iC7-Hybrid power converters for efficient, cost-effective electrolysis.

News

-

if (isSmallPicture) {

Danfoss acquires 1500 VDC converter technology and team to extend electrification portfolioWednesday, January 10, 2024

Danfoss acquires 1500 VDC converter technology and team to extend electrification portfolioWednesday, January 10, 2024Danfoss Drives are announcing the acquisition of the ACE300 product and the takeover of the product team from Finland-based company Ampner Oy, to extend the electrification portfolio with a dedicated 1500 VDC power converter. The product will be integrated within Danfoss Drives’ portfolio of Electrification Solutions with primary focus on Smart Grids and energy storage.

Green hydrogen: A critical balancing act

If we want to decarbonize hard-to-abate sectors, such as heavy industry, hydrogen production is going to play a crucial role. To support in the era of green hydrogen, we need to form clean hydrogen gas efficiently from renewable energy sources, and use it wisely. This means thinking strategically about how, when, and where we produce and consume it.

Danfoss offers grid-friendly solutions which are meticulously designed and validated for maximum energy efficiency. Featuring low harmonics and an adjustable power factor, our solutions ensure a cost-effective power supply for your electrolyzer, bolstering your green initiatives.

Read the latest issue of our Danfoss Impact Series on green hydrogen from renewable energy sources

Fuels of the future

Apart from green hydrogen, other potentially sustainable fuels of the future are methanol and ammonia Each of the fuels has its committed defenders and detractors. However green hydrogen is the most likely contender, since it is produced from renewable energy using electrolysis. Green hydrogen can be used in the form of fuel cells or in internal combustion engines. Hydrogen is already used in buses for public transport. In the maritime sector, hydrogen is a fuel best suited to fuel cells, charging batteries onboard battery-electric short-sea ferries, to extend their range.

Highlighted products

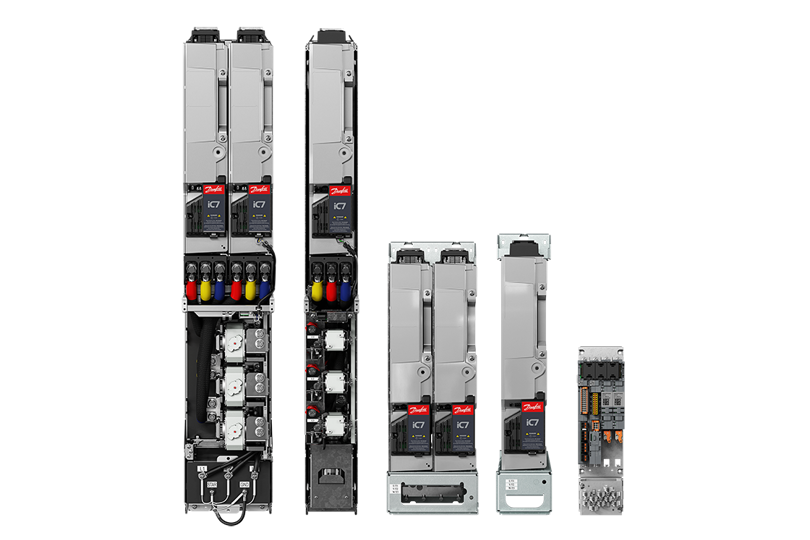

iC7-Hybrid

Open up for intelligent power conversion.

iC7-Hybrid is optimized for all power conversion applications and has an unrivaled power density with new filter technology.

Contact us

Ask our experts

If you're interested in learning more about Power-to-X and how our solutions could help in your projects, reach out to our experts. Helge Vandel Jensen, our Director Business Development in Electrification, is ready to help.