Predictive and preventive maintenance: Activate condition monitoring in HVAC/R applications

In HVAC/R applications, the introduction of condition monitoring functionality improves system uptime by preventing issues from occurring. Early prevention results in cost savings, fewer breakdowns, and optimized overall performance and comfort for the tenants, helping businesses to keep energy costs and meet commercial and climate targets. Condition-based monitoring technology is already integrated in new Danfoss variable speed drives controlling your HVAC/R systems and is ready to be activated.

Efficient system operation in your installation

Condition monitoring enables efficient HVAC/R system operation by employing 24/7 analysis of real-time data. An HVAC monitoring system not only helps to control electrical motors in fans, pumps, and chiller-compressors. It also provides insights and analytics to optimize overall performance of heating and cooling systems and reduce maintenance needs, with no need to connect to an external analytics device or cloud.

Prevent the unexpected in the HVAC system

Instead of waiting for problems to occur, condition monitoring allows for proactive maintenance measures, addressing potential issues before they become major problems. This approach helps to proactively manage challenges, by raising the flag to react early to typical issues arising in the installation. There is no need for unscheduled stoppage of fans, pumps or air conditioning compressors . Integrated CBM provides HVAC monitoring which empowers staff to schedule maintenance tasks into planned shutdowns - when qualified labor is available.

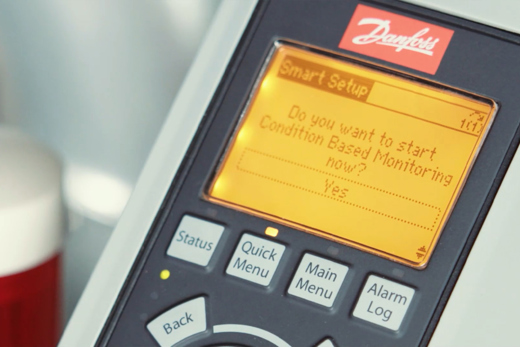

Freedom to activate: CBM is ready to run in your new drive

Using Danfoss drives, cost savings in ventilation, the air conditioning system, heating and refrigeration are easy to achieve. Condition monitoring functionality is integrated and operates inside your new drive, with zero to low additional investment in installed equipment. All you need to do is to activate it.

Most of the condition monitoring functionality uses the integrated sensors in the drive, which means no additional sensors are necessary. The condition monitoring algorithm runs internally in the drive, so no cloud connection or internet connection is required, either. With no cloud requirement, you can eliminate subscription fees and data transmission fees for remote cloud monitoring system s, too.

Benefits at the ready with an installed Danfoss drive

Condition-based monitoring (CBM) adds value in many aspects of operations, such as:

Reduced staff workload: 24/7 operational HVAC monitoring with no need for staff assistance

Easy monitoring of inaccessible assets, such as roof or basement fans

Avoided loss of refrigerated products due to unforeseen temperature and cooling system breakdown

Avoided losses due to ventilation breakdown in cleanrooms, including loss of manufactured products and cost of restarting operations

Avoided loss of reputation due to downtime in HVAC equipment and systems, for example in data center air conditioning units

No compromise on indoor air quality or comfort for individuals working and living in buildings

Information transfer is easy between the drive, PLC and/or BMS

Integration by fieldbus is possible

Leveraging condition monitoring

Incorporating a condition monitoring system in every HVAC system delivers many benefits, including risk reduction, cost savings, efficient system operation, and real-time data supervision.

Condition monitoring helps to predict performance

By activating the condition-based monitoring technology already integrated in Danfoss variable speed drives, HVAC operations and maintenance staff can predict performance issues and optimize overall operational efficiently. Communication and information transfer is easy between the drive, BMS, and PLC. Condition-based monitoring helps staff to overcome many daily challenges at drive level, in controllers located in the BMS, remote HVAC system monitoring, or control systems which communicate via fieldbus.

Highlighted products

VLT® HVAC Drive FC 102

Get intelligence, reliability and low total cost of ownership (TCO) in your heating, ventilation and air-conditioning installations, with this unique drive optimized for building automation systems.

Case stories

Danfoss first innovations

CBM has emerged from a history of Danfoss firsts in innovation. Danfoss drives differentiate from others in the market with intelligent functions embedded in the drive, to reduce the external components required.