We keep you going

In the chemicals industry, we know your plant never sleeps. It simply needs to keep working reliably, day in, day out, in the toughest environments and without any unexpected downtime. At Danfoss Drives, we enable just that with the highest-quality AC drives to keep you going.

Best-in-class AC drives for chemical plants

For your chemical plant to run at its absolute best, you need drives that enable peak performance. Designed with decades of industry know-how, our quality AC drives deliver best-in-class reliability and robustness. Their leading energy efficiency lowers your total cost of ownership and reduces carbon footprint to help in reaching the world’s climate goals. Further, predictive and condition-based monitoring are built into our drives to give you the intelligence you need to future-proof your systems. Our drives are also fully compatible with any motor or system, so you’re free to run the optimal system for your plant. Choose Danfoss as your AC drives partner and you can rely on us to keep you going.

How Danfoss Drives keeps you going

To meet the needs of the chemical industry, our AC drives focus on four key areas to ensure higher performance and lower operating costs.

Reliability and robustness

Life in a chemical plant is tough. Aggressive gases can damage components while cooling air contamination can cause PCB tracks and door seals to decompose. Knowing your drives are reliable and durable enough to handle the rigors of chemical production is therefore key. That’s why all our drives have at least conformal coated circuit board as standard, with the option of a reinforced conformal coating, high IP ratings, are ATEX compliant and can withstand high ambient temperatures of up to 50 °C.

Energy efficiency

All our AC drives are highly energy efficient, helping increase plant ROI and reduce TCO. They have excellent back channel cooling, reducing the need for air conditioning, as well as smart tools that lower energy use and application wear. Higher power density also means you can say goodbye to oversized drives, while at the same time lowering your energy consumption.

Simpler, more cost-efficient systems

Our drives can be used with 150m shielded or 300m unshielded cable starting from 1.5 kW without any additional output filters for motor connections. This saves investment, makes additional space requirement obsolete, lowers total loses in the system and provides full output torque on the motor shaft by avoiding voltage drop over the filter.

Predictive and condition-based monitoring

We keep you going for longer with predictive and condition-based monitoring capabilities that are embedded into our drives. This increases system uptime, extends the lifetime of your applications and helps to future-proof your system.

With the ability to act as sensors, analyze data, and connect freely, drives are vital elements in modern automation systems. Learn more about condition-based monitoring.

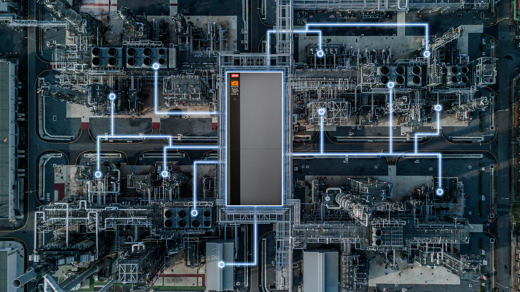

Integrated data and analytics on the edge

With integrated data generation and analytics capabilities embedded into our drives, you can analyze data close to your application. Combining the best of edge computing, cloud integration and industrial IoT, they deliver the right insights to help you unlock the full potential of your system – at a pace that suits you.

Engineering Guide for chemical applications

The specifications for refrigeration and control in chemical and pharmaceutical production processes are rigid. Only approved products for certain pressure ranges and harsh environments can be used. With an injection of Danfoss expertise and quality products you can be sure of high levels of reliability and safety, a long service life and high performance and energy efficiency. To learn more, read our guide "Planning and project engineering of AC drives in chemical and pharmaceutical applications".

The drive ecosystem

Whether you’re running or designing plants, we keep you going

There’s massive untapped potential in using the right drives. Our quality drives enable you to design or run the optimal system for your exact needs. They can use the best components from any motor or drive together with any gateway, cloud or analytics platform. And our global footprint means we always have drives available – no matter where you are. Ready to hear how we can keep you going?

Case studies

Drives components

Our VLT AutomationDrive FC 301, FC 302 and VACON NXP Air Cooled drives are the most popular and versatile stand-alone drives in our chemicals portfolio. They adhere to the highest standards in quality, reliability and energy efficiency, and are always available if you need replacements.

-

if (isSmallPicture) {

VACON® NXP Air Cooled

VACON® NXP Air CooledDesigned for a broad range of demanding applications, focusing on higher power sizes and system drives.

-

if (isSmallPicture) {

VLT® AutomationDrive FC 301 / FC 302

VLT® AutomationDrive FC 301 / FC 302The VLT® AutomationDrive FC 301 / FC 302 is designed for variable speed control of all asynchronous motors and permanent magnet motors. It comes in a standard version (FC 301) and an advanced high dynamic version (FC 302) with additional functionalities.

Drives systems

If you run more complicated applications that simply need to keep going, our drives systems are exactly what you need. With our VACON NXP System Drive and VLT AutomationDrive FC 302 System Drive, you get fully configurable drive line ups that can be built to any specification.

-

if (isSmallPicture) {

VACON® NXP System Drive

VACON® NXP System DriveConfigured and assembled to meet your needs whether you need to control one or several motors.

-

if (isSmallPicture) {

VLT® AutomationDrive FC 301 / FC 302

VLT® AutomationDrive FC 301 / FC 302The VLT® AutomationDrive FC 301 / FC 302 is designed for variable speed control of all asynchronous motors and permanent magnet motors. It comes in a standard version (FC 301) and an advanced high dynamic version (FC 302) with additional functionalities.