Unleash the intelligence from within

Whether you operate complex industrial production lines, large HVAC systems, food processing plants or breweries, switch to our intelligent drives with built-in predictive- and condition-based monitoring and enjoy all the opportunities they offer. Opportunities that will enable you to optimize your applications quickly and easily so you can minimize downtime. While doing less

Predictive and condition-based monitoring powered by intelligent drives

To unleash the full potential of your systems means making them smarter – an often demanding task. However, our drives have intelligence embedded in them so you can easily generate and store valuable insights in the cloud or whatever on-premises system you have in place. For predictive- and condition-based monitoring that is guaranteed to help you get the most out of your equipment.

In fact, by embedding edge intelligence into our drives, we’ve made smart systems accessible for every manufacturer in every industry. Designing our drives to easily and accurately determine when it’s time for you to carry out maintenance on an application or to fully optimize it – so that your systems can live up to every expectation. Every time

Helping Heineken digitalize operations

When brewer Heineken Netherlands Supply made the decision to upgrade the maintenance system at its Den Bosch brewery, it turned to Danfoss Drives. Download our case story and read up on the solutions we chose for our client, what processes we went through to optimize the brewery’s applications and production line, and how, in the end, Heineken was able to unleash the intelligence from within its systems

Better data security and lower data usage

In processing data on the edge, intelligent drives avoid transmission of raw data to the cloud or any on-premises data storage/automation system – thereby reducing how much data is transferred and lowering the risk of any cyberattacks. For an overall simpler and safer procedure that requires less bandwidth.

Lower investments

By using your drive as a smart hub for external sensors – be they pressure, vibration, or otherwise – make room for condition-based monitoring and process control while avoiding the need for additional sensors and gateways.

All-encompassing support

Our drives deliver intelligence not only to an application, but the system that surrounds it. Going beyond what’s expected of them to support your entire operation.

Fully independent

Our drives work with any kind of system or motor, be it induction, reluctance, or permanent magnet. And so, with the freedom to choose the best motor technology for your application, enjoy maximum efficiency and performance from your equipment.

The hotel that’s fully booked for a better future

To make the Alsik one of Denmark’s most sustainable luxury hotels, its owners had to think green from the ground up. With Danfoss’ energy efficiency solutions clearing their mindsets – and the indoor air environment. Discover how our intelligent drives enabled full optimization of the hotel’s HVAC system.

Our drives in action

With our products, get ready for your digital transformation

Get even more drive from your HVAC system

Improve reliability and lower total cost of ownership with this unique VSD which has been optimized for building automation systems. And keep lifecycle costs to an absolute minimum no matter the environmental conditions.

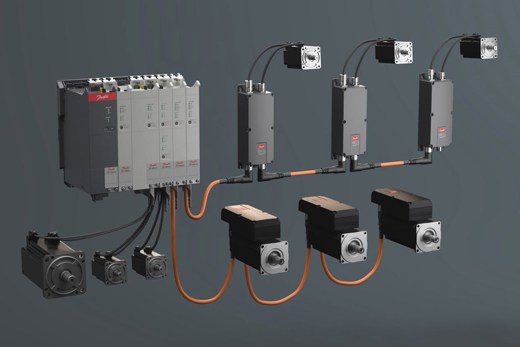

Flexible servo drive concept

VLT® FlexMotion™ is designed to meet the requirements of tomorrow’s machine architecture today. Its modular platform provides you one system capable of creating a diversity of machine concepts based on three servo product lines.

Maximum energy efficiency for water and wastewater applications

Featuring a wide range of powerful functions as standard, all of which can be boosted with performance-enhancing features, the VLT® AQUA drive is perfectly suited to your water industry operations.

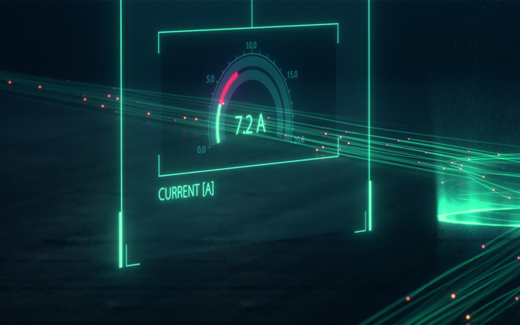

Condition-based monitoring in action

Watch this demonstration to see how a drive with condition-based monitoring capabilities can alert you in advance of typical motor faults, enabling you to plan maintenance ahead of time.