Serving success

Today, finding ways to cut energy consumption while increasing productivity is absolutely achievable. We help you to maximize efficiency in food and beverage operations, adapt successfully to changing consumer demands and perform at best-in-class standards. Look forward to lower OPEX, more uptime, and less resource waste throughout your operations.

Enhance technical performance

Boost efficiency, speed, and torque in your application, with ultra-compatible drives. These drives optimize any motor and speak the language of any PLC protocol. This means you can keep the motor you prefer or upgrade to a new motor technology, with no need to change out your drive.

Danfoss supports your system with:

- Fast, easy integration of drives to any PLC

- More uptime, using condition-based monitoring functionality

- High reliability, longevity, and optimal TCO (total cost of ownership)

- Round-the-clock lifecycle service support

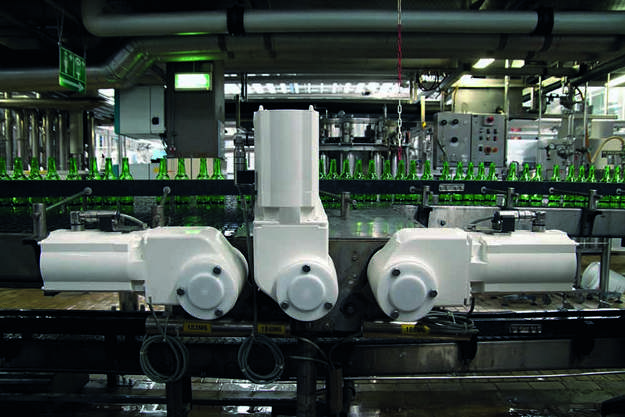

Pioneering bottling line at Brasserie Caulier

Brasserie Caulier now gets full benefit of its Legendre Conveyor systems with the new iC7-Automation drive.

Elevate ESG

Achieve more sustainable productivity in your operations, to reach climate targets and minimize OPEX. Extend the uptime, efficiency, and longevity of your systems. Decarbonize painlessly, by using less water and power while boosting output and profitability.

Curious to investigate your productivity improvement potential?

Estimate payback time of an investment in energy efficiency technology.

Enter the General information and Efficiency data (left), then check Results (right) for estimated reduction in energy consumption, CO2 emission, and payback time. Try different values for [Number of motors] and [Nominal power per motor] to adjust the results.

Estimate ESG impact

This ESG impact tool provides an estimate only. For a precise calculation, use the MyDrive® Energy tool or contact your local Danfoss office.

Kohberg Bakery

Secure your systems for the future and harvest data for energy optimization, with iC7-Automation.

Accelerate business

Are you a food or beverage producer? We can help you optimize your business while serving your customers in the best way. Use drives from Danfoss to improve uptime and reduce running costs, while meeting your ESG targets at the same time. We offer you ways to accelerate productivity, reduce spare part inventory, and minimize energy as well as water consumption.

Are you a system integrator or original equipment manufacturer (OEM)? We can assist you in achieving decarbonization without sacrificing profitability. Our premium drives and gear motors can enhance the performance of your machines, making them more appealing to customers. We also help you and your customers reach environmental, social, and governance (ESG) goals by improving the sustainability of your equipment. We support you in improving production efficiency and catering to your target market. Additionally, we offer visibility in the market through success stories and other marketing initiatives by Danfoss.

Get servo performance encoder-free, with Integrated Motion Controller. For high-precision positioning and synchronization in a variable-speed drive.

Together, we will accelerate your business

Watch our on-demand webinar on Sustainable Productivity in Food and Beverage to discover how you can gain a competitive edge by partnering with Danfoss Drives.

- Reduce energy consumption and significantly reduce energy costs

- Increase productivity with intelligent drives

- Achieve greater efficiency and reliability

- Minimize CO₂ emissions and resource waste

- Reduce expensive downtime and maintenance cost