Reduce risk

Are you willing to risk unnecessary downtime?

Have you experienced

- Unplanned production stops?

- Expensive loss of production due to downtime?

- Failures to critical equipment “out of the blue”?

- Motors and driven loads failing?

The cause is often poor network quality due to harmonic distortion. Harmonic distortion causes damage to critical equipment leading to failures.

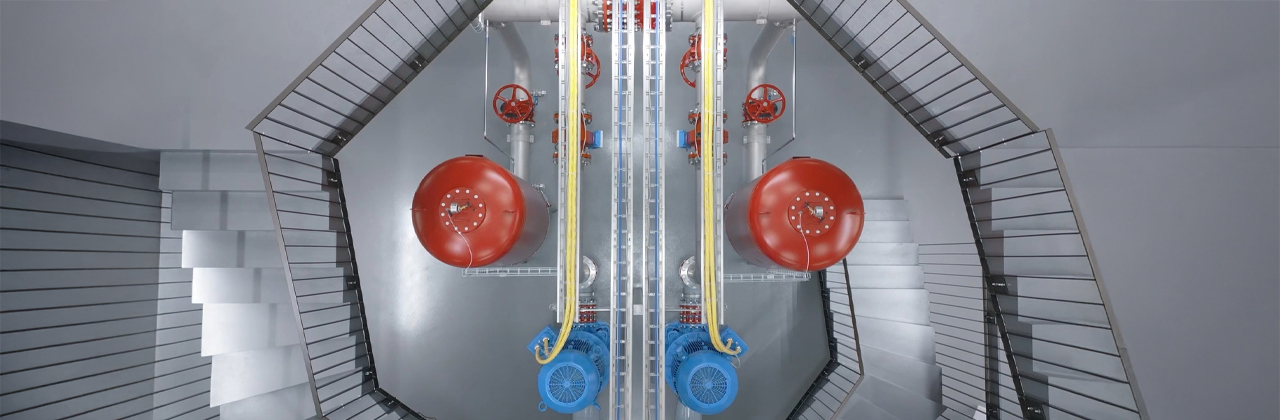

Adding drives (VSDs) to your system can improve network quality, massively reduce energy consumption, and manage driven loads to ensure breakdowns are minimized with good maintenance planning. Managing harmonic distortion using drives brings stability to the electrical grid and reduces outages.

The whole topic of network quality and how it impacts greenhouse gas accounting can be daunting. Luckily you don’t need to be the expert. Danfoss experts stand ready to support your business with expert advice and VSD solutions for energy savings and cost-effective harmonic mitigation.

Contact us for advice.

Impact on OPEX

Are you paying too much for energy (OPEX)?

How does network quality affect operating costs? Poor power quality results in unnecessarily high electricity bills.

Check the electricity bill:

- You may be surprised to find out how much you pay for poor power quality that does not contribute to operating your facility or plant, it just costs you money.

- The cost of distortion power (kVAr) can be higher than the power being used to actively run the plant (kVA or kW).

Carbon accounting