Increase uptime and efficiency in your systems

In today's fast-paced industrial landscape, the importance of proactive maintenance strategies cannot be understated. Predictive maintenance, enabled by intelligent drive edge computing and condition monitoring, has emerged as a powerful tool to optimize equipment performance, increase uptime, and reduce maintenance costs. In this article, we will explore the concept of predictive maintenance in relation to condition monitoring and highlight its numerous advantages in terms of economic efficiency, equipment performance, and cost savings.

Advantages of predictive maintenance condition monitoring

Increased economic efficiency

By continually collecting and monitoring data, predictive maintenance ensures that equipment issues are identified before they escalate, minimizing the risk of downtime. This proactive approach enhances economic efficiency by preventing costly unplanned shutdowns and reducing overall maintenance expenses.

Higher uptime

The constant monitoring of data allows for early identification of any changes or abnormalities in equipment performance. By addressing potential issues before they lead to failure, predictive maintenance maximizes equipment uptime, ensuring smooth operations and minimizing disruptions.

Extended machine/equipment lifetime

Through timely maintenance and addressing potential issues proactively, predictive maintenance helps to optimize the performance and lifespan of machines and equipment. By identifying and rectifying issues before they cause severe damage, the need for expensive repairs or premature replacement is significantly reduced.

Optimal preventive maintenance timing

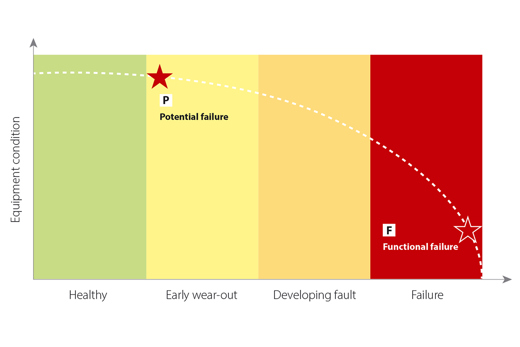

Predictive maintenance utilizes condition monitoring data to determine the best point in time for maintenance activities. By analyzing the health state of components and following the degradation curve, maintenance can be triggered before functional failure occurs. This approach ensures that preventive maintenance activities are carried out when they are most needed, preventing unnecessary downtime and reducing costs associated with reactive repairs.

Edge analytics and machine learning for better machine performance

The collected data from condition monitoring provides valuable insights into the performance of machines and equipment. By analyzing this data using edge analytics and applying machine learning algorithms, manufacturers can identify patterns, trends, and potential areas for improvement. This information can be used to optimize machine efficiency, resulting in better overall performance and increased productivity.

Significant savings potential of condition-based maintenance (CBM)

A study commissioned by the European Commission highlights the significant savings that can be achieved through a properly functioning condition-based maintenance (CBM) program. The study estimates savings of 8-12% over traditional preventive maintenance schemes. Additional benefits reported include a reduction in maintenance costs by 14-30%, downtime by 20-45%, breakdowns by 70-75%, and an improvement in production by 15-25%.The algorithm compares the actual cavitation signature against user-defined threshold levels. If the values exceed the set thresholds for a predefined time, the event is flagged as cavitation.

Furthermore, repair costs for failed assets are typically 50% higher than if the problem had been addressed prior to failure. Reports from companies like Fusheng in the compressor industry indicate that timely repairs resulted in a 15% reduction in mean time to repair (MTTR) and a 20% increase in the first-time fix rate.

How analytics are leveraged in predictive maintenance

Predictive maintenance relies on advanced analytics to leverage the collected data effectively. This includes:

- analyzing component lifetime and fault information

- implementing condition-based maintenance strategies

- establishing baseline information for comparison

- utilizing machine learning algorithms to identify patterns and make accurate predictions

These analytics enable manufacturers to prevent unexpected issues, optimize availability, reduce wear and tear effects, extend equipment lifetimes, and create predictable long-term cost savings through tailored maintenance plans.

Maximize productivity with intelligent edge computing

Predictive maintenance, enabled by intelligent drive edge computing and condition-based monitoring, helps manufacturers achieve optimal equipment performance, increased uptime, and cost savings. By systematically ensuring the optimal condition of machinery and addressing potential issues before they escalate, businesses can avoid unexpected downtime, extend equipment lifetimes, and maximize overall productivity. Embracing predictive maintenance not only reduces complexity but also provides actionable insights that take the guesswork out of maintaining equipment, ensuring a competitive edge in today's rapidly evolving industrial landscape.

Highlighted products

Danfoss products using condition-based monitoring

-

if (isSmallPicture) {

VLT® Refrigeration Drive FC 103

VLT® Refrigeration Drive FC 103FC 103 is dedicated to controlling compressors, pumps and fans for significant energy savings in refrigeration plants.

-

if (isSmallPicture) {

VLT® AQUA Drive FC 202

VLT® AQUA Drive FC 202VLT® AQUA Drive FC 202 controls all types of pumps and comes equipped with a cascade controller.

-

if (isSmallPicture) {

VLT® AutomationDrive FC 301 / FC 302

VLT® AutomationDrive FC 301 / FC 302The VLT® AutomationDrive FC 301 / FC 302 is designed for variable speed control of all asynchronous motors and permanent magnet motors. It comes in a standard version (FC 301) and an advanced high dynamic version (FC 302) with additional functionalities.

-

if (isSmallPicture) {

VLT® HVAC Drive FC 102

VLT® HVAC Drive FC 102This tough and savvy FC102 drive enhances pump and fan applications in building management systems, and runs outdoors in most climates.

-

if (isSmallPicture) {

VACON® 100 X

VACON® 100 XA drive for indoor and outdoor applications that withstands high pressure and vibration levels, water, heat and dirt.

-

if (isSmallPicture) {

VACON® NXP System Drive

VACON® NXP System DriveConfigured and assembled to meet your needs whether you need to control one or several motors.

-

if (isSmallPicture) {

VACON® NXP Liquid Cooled Common DC Bus

VACON® NXP Liquid Cooled Common DC BusBrings the benefits of liquid-cooling into common DC bus systems in demanding situations. Active Front-end (NXA), Non-regenerative Front-end (NXN), Brake Chopper (NXB) and Inverter (NXI) configurations are available.

-

if (isSmallPicture) {

VACON® NXP DC/DC Converter

VACON® NXP DC/DC ConverterMaximizes the energy yield in hybrid solutions and helps improve performance by bringing energy support close to the consumption.

-

if (isSmallPicture) {

VACON® NXP DCGuard

VACON® NXP DCGuardVACON® NXP DCGuard™ delivers reliable short-circuit protection of DC grids for full selectivity between DC grids, and ensures fast disconnection in the event of a fault.

Danfoss first innovations

CBM has emerged from a history of Danfoss firsts in innovation. Danfoss drives differentiate from others in the market with intelligent functions embedded in the drive, to reduce the external components required.

Case stories

-

if (isSmallPicture) {

How did this smart factory reach carbon-neutral?

How did this smart factory reach carbon-neutral?POLAND: The new Danfoss production hall in Grodzisk Mazowiecki has reached carbon-neutrality, thanks to full electrification, energy-saving solutions such as Danfoss drives, and energy from renewable sources.

-

if (isSmallPicture) {

Refrigeration systems preserve apple quality using VSDs with integrated condition monitoring and DrivePro Remote Monitoring service

Refrigeration systems preserve apple quality using VSDs with integrated condition monitoring and DrivePro Remote Monitoring serviceITALY: At Rivoira Group, VLT® drives with built-in condition-based monitoring help preserve fruit perfectly by ensuring utterly reliable refrigeration.

-

if (isSmallPicture) {

How does Beat the Storm deliver more fun for less CO2?

How does Beat the Storm deliver more fun for less CO2?DENMARK: Universe Science Park saves on both power bill and emissions for its wind tunnel attraction “Beat the Storm”, with the intelligent VLT® HVAC drive.

-

if (isSmallPicture) {

Driving maximum uptime in aseptic pharmaceutical production

Driving maximum uptime in aseptic pharmaceutical productionDENMARK: A leading global pharmaceutical company was determined to find an intelligent HVAC solution to prevent downtime with real-time system monitoring and customizable instant alarms. Plus, the solution needed to fit within the organization’s ambitious digitalization strategy. The solution: Danfoss VLT® HVAC Drive FC 102 with integrated condition-based monitoring.

-

if (isSmallPicture) {

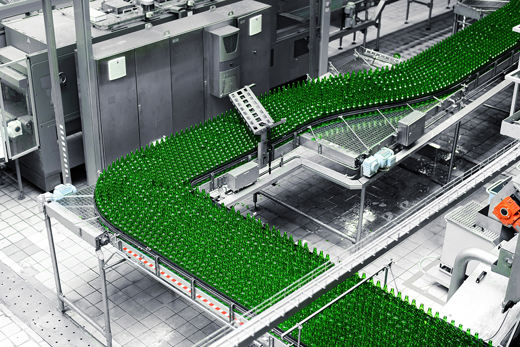

Brewing up real change at HEINEKEN

Brewing up real change at HEINEKENNETHERLANDS: HEINEKEN understands that to meet demand, its production line must always be up to the task – with all assets expected to deliver a consistently reliable and excellent performance. At Den Bosch brewery, the tough working environment posed several challenges. The solution was an upgrade using drives with integrated condition-based monitoring.