Designed for a wide range of applications, the ICAD B uses the latest digital connectivity options to simplify set-up, installation and operation

“With the new ICAD B, we’ve addressed some of the most relevant pain points for industrial refrigeration professionals,” says Alejandro Figueroa Lopez, Head of Product Management Danfoss Industrial Refrigeration. “The result is an actuator that takes digital integration, usability and reliability to the next level.”

Improving reliability in low-temperature applications

The ICAD B is designed for a wide range of applications and includes several features to maximize reliability in harsh environments. The mounting mechanism has a fully hermetic design, so you get a tight seal between the ICAD and ICM. This prevents moisture or humidity from penetrating the seal. The coupling doesn’t need grease or additional materials, which also eliminates the need for maintenance or cleaning. The new mounting design is also easier for installers to work with, as they only need to use two screws for mounting. The coupling can also be positioned in any direction. And installers can rest easy, knowing the new design has been thoroughly tested in all conditions. The Danfoss development team has extensively tested and validated the new design over extended periods of time, both in the lab and in the field. And the results were that it performed flawlessly every time.

Simplifying set-up and operation

The next pain point on the list was the time required for installers to set up and maintain motorized valves. Here, the Danfoss team tapped into the latest digital technology to make life easier for installers. The ICAD B comes with its own smartphone app that enables installers and operators to access all valve functions remotely. The app includes a quick set-up wizard, a self-diagnostics tool and support for preventative maintenance scheduling. The smartphone app is a real gamechanger, and will help industrial refrigeration professionals to ensure continuous, trouble-free operations for their customers, without having to climb the valve.

Enabling full integration with control systems

The final step for the Danfoss team was to ensure the new actuator could seamlessly integrate with industrial refrigeration control systems. “Our partners tell us that they’re looking to move away from analog communication. They want the flexibility and control that digital connectivity provides.” To meet this demand, the new ICAD B supports two data communication options out-of-the-box: Modbus RTU over RS485 and Modbus TCP IP over Ethernet. “Using these connectivity options, customers can fully integrate each ICAD to the control system for set up, parameter adjustment, monitoring and control,” explains Alejandro Figueroa Lopez, Head of Product Management Danfoss Industrial Refrigeration. In addition to providing the sought-after flexibility, this type of data communication saves money, as it reduces the need for wiring and Input/Ouput at PLC/control system.

With its reliability, user-friendly design and digital integration capabilities, the new ICAD B will help Danfoss customers prepare for the next phase of industrial refrigeration, as Alejandro Figueroa Lopez, Head of Product Management Danfoss Industrial Refrigeration points out. “For decades, Danfoss has offered its customers innovative industrial refrigeration solutions. Now that the industry is moving towards digital transformation, our new actuator arrives at just the right time, to help our customers take motorized valves control and connectivity to the next level.”

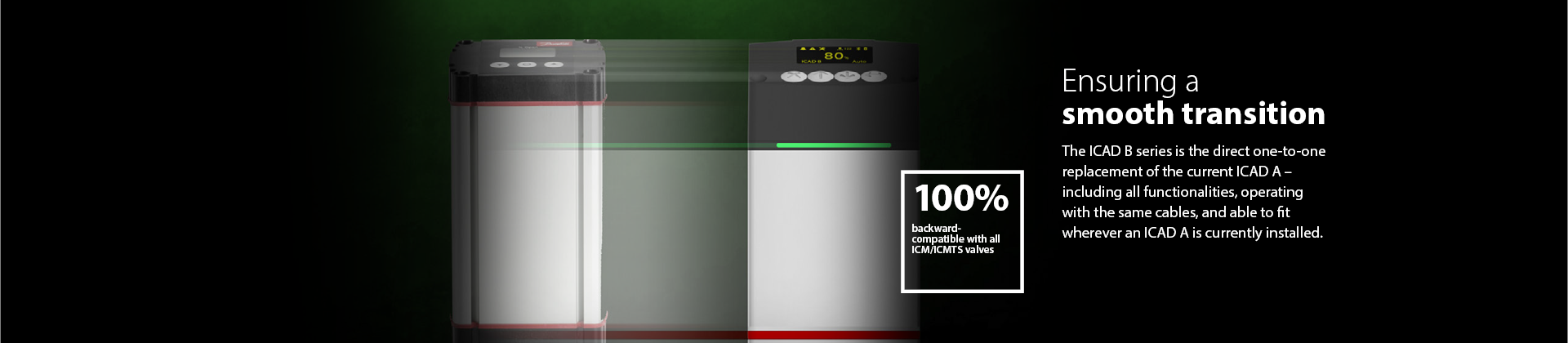

ICAD B Motorized valve control

Designed for a wide range of applications, the ICAD B takes motorized valve control to the next level – ensuring enhanced user experience, reliable operation, and easy integration to control systems. The ICAD B is all about connecting the dots and reducing complexity.