50 years of steering innovation

Danfoss began producing hydrostatic steering units back in the 1960s. Since then we have introduced many new variants, adapting to both market and regulatory needs.

In early 2000, Danfoss developed the first generation of electrohydraulic steering products to fit a wide range of machine types. With GPS automatic steering, variable steering ratio and joystick steering, we made it possible to help customers increase their productivity and comfort.

In 2016, Danfoss has been promoting our second generation of electrohydraulic steering components for some time now. We have optimized it and added new features for intelligence and safety to meet the market’s demand. The Danfoss OSPE PVED-CLS electrohydraulic actuator is the first intelligent steering sub-system to integrate all safety functionality in the valve. Safety functions are designed to SIL2 (IEC 61508), PL d (ISO 13849) and AgPL “d” (EN 16590).

Many new products are underway to further meet our customers’ demands or strengthen our existing portfolio – from basic hydraulic steering units to adaptations for higher road speed, electrohydraulics or full SBW solutions where the steering column can be removed to optimize vehicle design.

Related products

-

if (isSmallPicture) {

Flow Control Valves

Flow Control ValvesTemperature and pressure compensated flow controls allow precise volumetric control. Suitable for pressures up to 3600 psi, Vickers by Danfoss flow controls are available with (bypass type) or without (restrictor type) integral relief valves. Adjustable flow control valves are suited for applications requiring flow regulation without pressure compensation.

-

if (isSmallPicture) {

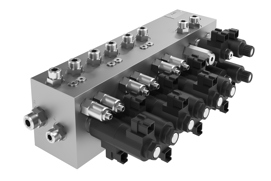

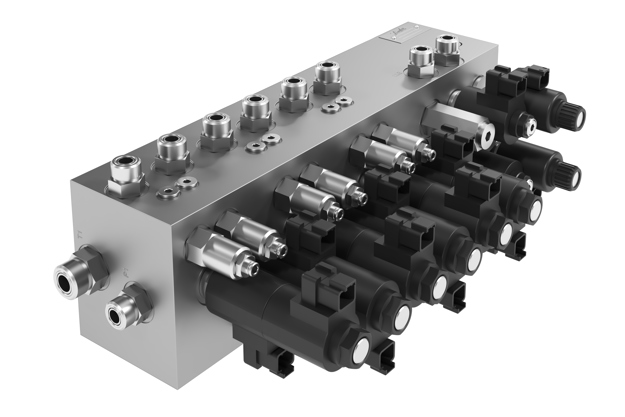

Hydraulic integrated circuit (HIC)

Hydraulic integrated circuit (HIC)Danfoss ICS specializes in Hydraulic Integrated Circuits (HICs) allowing customers to use our broad portfolio of cartridge valves to create innovative solutions for optimal machine control and performance.

-

if (isSmallPicture) {

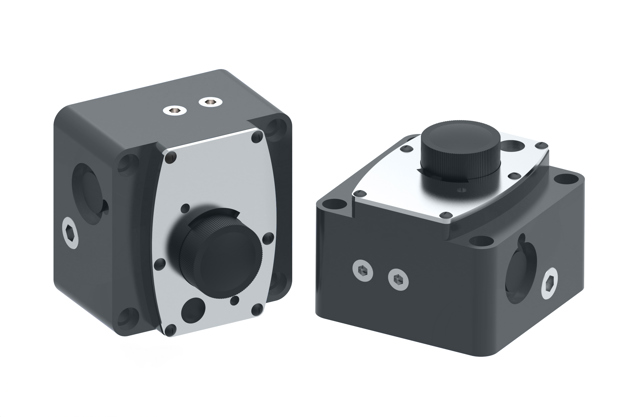

Brake valves

Brake valvesAchieve the perfect feel with Danfoss brake valves. With decades of experience designing custom solutions for mobile machinery, Danfoss has perfected the art of turning calculations into a braking system that gives you – and your operators – exactly what you want. With our full range of power, manual and hybrid brake valves, we can help you increase machine performance and productivity.

-

if (isSmallPicture) {

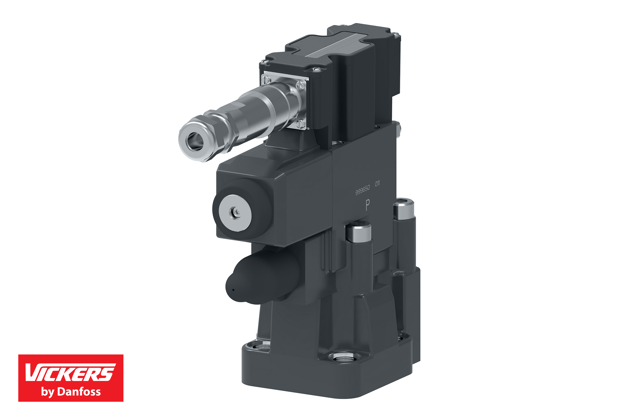

Proportional Pressure Valves

Proportional Pressure ValvesVickers by Danfoss pressure reducing/relieving valves are three-way valves that provide a controlled output pressure as a function of electric current, regardless of system pressure or flow (within the valve’s limits). With pressures up to 350 bar [5,000 psi] and flows up to 400 l/min [106 US gal/min], these valves have a variety of applications, including: single-acting cylinder position control (e.g., combine header height control; clutch or brake pressure control; and pilot signal to a directional control valve.

-

if (isSmallPicture) {

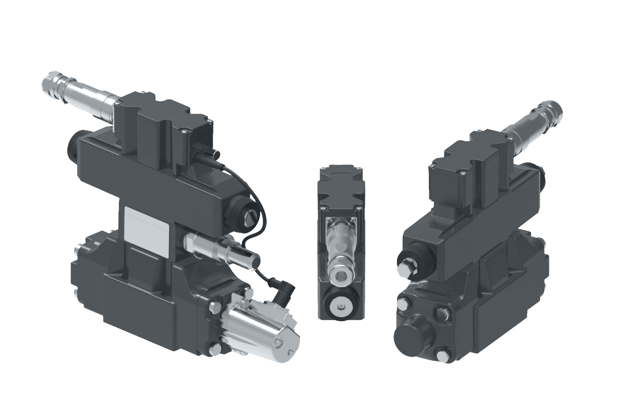

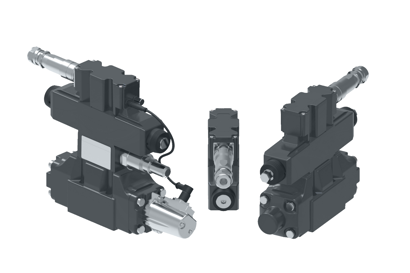

Proportional Directional Valves

Proportional Directional ValvesVickers by Danfoss proportional directional valves offer a wide variety of features, flow rates and performance levels for industrial and mobile applications.