Discover how AB InBev Hoegaarden® achieved next-gen energy efficiency with iC7-Automation and VLT® OneGearDrive®

Conveyors are the veins of a brewery, letting the bottles move from filling to labeling to palletizing with ease and precision. It is therefore crucial that conveyor upgrades ensure minimal risk of complications and unplanned downtime. For some, this means opting for the usual reliable technology, even if this is not the most energy efficient pick. For others, it means going for the best of both worlds.

When upgrading their more than 20-year-old bottle line, AB InBev Hoegaarden® chose Legendre Conveyors-Actemium as partner and seized the opportunity to take on a next-gen drive option, the iC7-Automation. As this drive had already been tested along with Danfoss' VLT® OneGearDrive® PM gear motors, the risk of unforeseen challenges was low. Now, the line is ready for another 20 years—with market-leading IE5 efficiency.

The challenge: Upgrade with minimum risk

AB InBev is the world’s largest beer producer overseeing well over 200 breweries globally, including Hoegaarden®—known for their iconic Belgian wheat beer. The brewery faced the imperative task of upgrading an important bottle line. As any amount of downtime is both inconvenient and expensive, it was important for them to choose a solution that could be seamlessly integrated with a minimum risk of abnormalities.

On the other hand, there was a strong wish to reduce energy consumption as much as possible. With rapid advancements in drive technology as well as demands for energy efficiency, they would potentially find themselves migrating to next-gen technology in no more than 7-10 years. Usually, a new bottle line is expected to last around 20 years.

The solution: iC7-Automation for proven performance

Relying on their supplier Legendre Conveyors-Actemium and their positive experience with the high quality and committed customer support offered by Danfoss, AB InBev Hoegaarden® was confident in exchanging their initial choice with cutting-edge iC7-Automation drives and VLT® OneGearDrive® motors. This was reinforced by successful deployments of the same combination in other breweries, proving their efficiency and reliability, and minimizing the risk of unforeseen issues.

By embracing the latest technology over their customary drive VLT® AutomationDrive FC 302 and third-party motors, AB InBev Hoegaarden® has not only enhanced energy efficiency but will also ensure easy integration with future upgrades as the iC7-Automation receives regular updates to maintain optimum compatibility. Leaving the brewery with a thoroughly future-proof solution.

Benefits of combining iC7-Automation and VLT® OneGearDrive

- The combination has already been tested, ensuring low risk commissioning

- iC7-Automation software is frequently updated to maintain compatibility with future additions

- iC7-Automation is a secure-by-design solution offering both hardware and software protection

- VLT® OneGearDrive is suitable for cleanroom production areas with protective coating and a smooth surface to withstand thorough and regular cleaning

- iC7-Automation features Automatic Motor Adaptation to allow even faster commissioning

The outcome: Fast upgrade to IE5 efficiency with scalability

Despite the project's initial three-week schedule, the experienced team from Legendre Conveyors-Actemium—with support from Danfoss—completed the commissioning in just two days. Proving without a doubt that with the right partner, embracing new technology can be just as low risk as the standard procedure—and deliver even better results.

Thanks to the knowledge and a thorough preparation of the Legendre Conveyors-Actemium employees and the excellent support from Danfoss Drives Belgium, the commissioning was completed in a short time with minimal disruption.

By exchanging their prior induction motors with the VLT® OneGearDrive permanent magnet gear motors, AB InBev Hoegaarden® has enhanced energy efficiency, aligning with their ongoing efforts to optimize resource use across the value chain. Looking into the future, they can now rest assured that the veins of their iconic brewery are fit to meet coming demands with easy scalability, state-of-the-art performance, and rock-solid reliability.

Products installed

iC7-Automation

Need more uptime and precision motor control?

iC7-Automation is a highly flexible drive designed for demanding industrial applications.

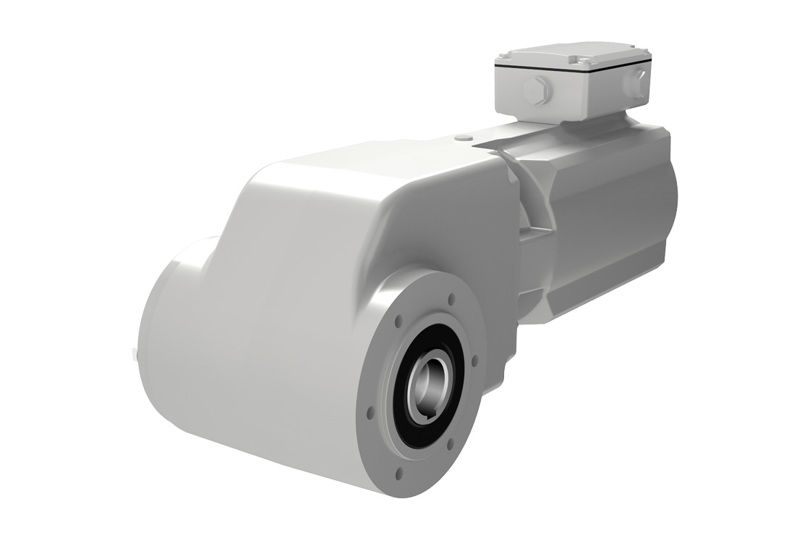

VLT® OneGearDrive®

A highly efficient, permanent magnet, three-phase synchronous motor coupled with an optimized bevel gear box and IE5 ultra premium efficiency.

Contact us

To learn more, please contact your nearest Danfoss Drives sales office.