SONDEX® traditional plate heat exchangers are the go-to choice for standard duties. The versatile design and high thermal efficiency make them the perfect solution for a wide range of applications.

What does that mean for you?

We have specialized in developing plate heat exchangers in close cooperation with our customers. Because we understand the process behind your applications, each solution is customized and configured to suit you and your business.

Our extensive plate portfolio and pattern options ensure that we always have a solution that is exactly right for you. Our patterns create the ideal turbulent flow and make the best use of the available pressure drop for any duty.

Always the efficient choice

We design single-pass solutions when possible, as they are the preferred choice for almost all duties. With all connections on the head, you do not need to disconnect the heat exchanger from the piping to perform inspection, cleaning, or service. Go with a SONDEX® heat exchanger for simple, fast, and easy installation and maintenance.

With minimal space requirements, considerably lower energy consumption, and reduced number of plates needed for optimal performance, SONDEX® heat exchangers are designed with tomorrow in mind.

Features and benefits

Experience the benefit of an individually customized solution that perfectly matches your requirements and lowers your energy consumption.

High performance for a low pressure drop eliminates unnecessary burdens on your system and optimizes overall system performance.

The design results in a compact solution with a small footprint, simple installation, and easy access for maintenance.

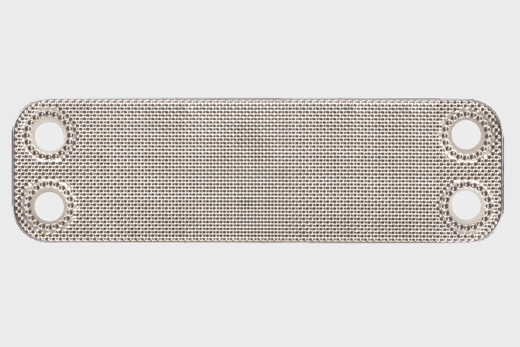

Micro plate technology

Our heat exchangers with the new state-of-the art Micro Plate™ technology feature next-generation efficiency and performance – giving you more from your district heating and cooling applications.

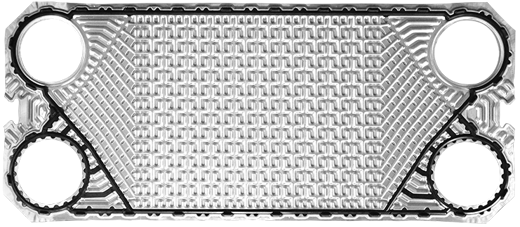

SONDEX® Free flow patterns

The SONDEX® Free Flow pattern is designed to treat media that is unsuitable for regular heat exchangers due to high viscosity, fiber and particle contents, or considerable risk of fouling.

Applications

- HVAC industry - e.g. district cooling solutions using seawater and groundwater as cooling source - e.g. district heating solutions using, for example, solar and geothermal energy as heating source

- Marine/offshore industry - e.g. central and lubrication oil cooling

- Dairy/food/beverage industry - e.g. pasteurization, heat recoveries, and duties that require gentle treatment

- Sugar industry

- Biogas industry

- Pulp and paper industry

- Heavy industry

- Mining industry

- Petrochemical industry

- Chemical industry - e.g. waste heat recovery from condenser water

Technical specifications

- Connections from DN25 to DN600

- (Frames designed according to FEA and PED 2014/68/EU (EN13445) and ASME sec VIII, Div. 1 construction standards)

- Plate materials: AISI 304/316, titanium, SMO, Hastelloy. Other materials available upon request

- Gasket materials: EPDM-HT, NBR-HT, Viton. Other materials available upon request

- Plate heights up to 5.5 m (18 ft)

- Flow rates up to 7,200 m3/h (31,700 gpm)

- Working pressure up to 25 bar (363 psi)

Related products

Coming soon...

Coming soon...