Ensure maximum production and efficiency

Boost overall performance and energy efficiency of your AC drive system by replacing outdated AC drives with the latest technology.

With the proactive approach of planning the replacement well in advance, you can fit the retrofit into your timeline and adjust for any production restrictions that may occur. This keeps your production running with minimum delay, and you can enjoy a reliable budget without unexpected costs.

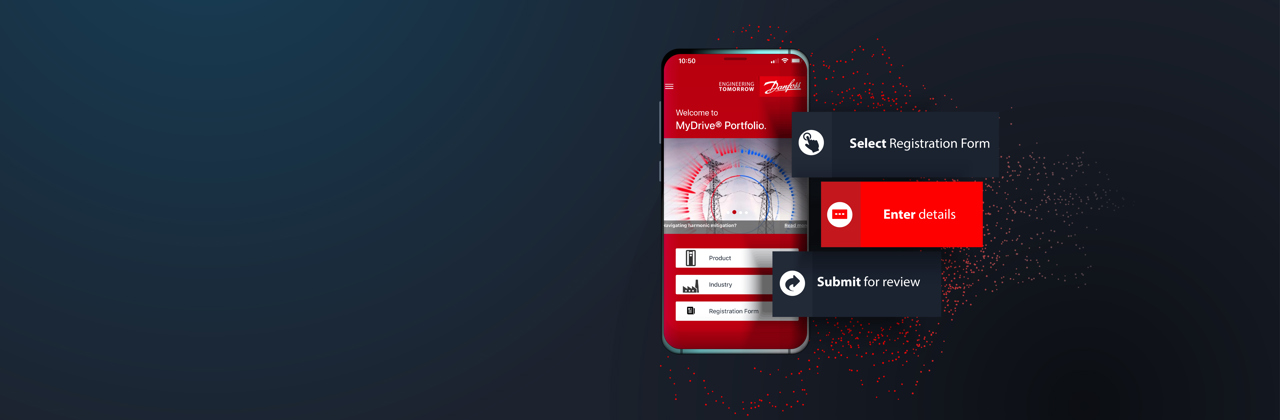

How it works

Features and benefits

Adopt the latest technology with the right drive for the application

- Achieve additional process and energy efficiency in your existing system

- Only pay for what you need

- 100% compatibility and durability

- Ensure best protection for your other equipment

Coordinated replacement of large volumes of AC drives

- Mitigate installation costs

- Benefit from Danfoss expertise to ensure fast and easy replacement selection, commissioning, and maintenance planning

Replacement schedule

- Efficiently replace the outdated products with latest technology AC drives

- Ensure maximum uptime with careful planning

- Avoid unexpected cost for emergency drive support

FAQ

Case studies

-

if (isSmallPicture) {

Site assessment secures maximum uptime for K+S

Site assessment secures maximum uptime for K+SGERMANY: Thanks to DrivePro® Life Cycle Services, a K+S potash mine got more uptime and a quick retrofit resulting in a better bottom line.

-

if (isSmallPicture) {

Bringing clean drinking water to rural Kenya with 100% renewable resources

Bringing clean drinking water to rural Kenya with 100% renewable resourcesA solar-powered desalination plant in Kenya gives the community affordable, clean, and sustainable drinking water and irrigation water.

-

if (isSmallPicture) {

Hospital selects DrivePro® programs to keep costs down, maintain efficiency

Hospital selects DrivePro® programs to keep costs down, maintain efficiencyAs the largest regional medical center in San Joaquin County, St. Joseph’s Medical Center in Stockton, Calif., has 359-beds, employs over 400 physicians and more than 2,400 employees. Operating the HVAC mechanical equipment for a facility this large is a huge energy-conservation challenge. That's why St. Joseph’s made the decision to use variable frequency drives (VFDs) on HVAC pump and fan motors —a decision that continues to pay off today, thanks to an innovative upgrade plan using Danfoss VLT® Drives.

-

if (isSmallPicture) {

Coca-Cola FEMSA enjoys more uptime with DrivePro®

Coca-Cola FEMSA enjoys more uptime with DrivePro®Since investing in DrivePro® services, the bottling lines at Coca-Cola FEMSA in Brazil have dramatically improved in reliability and availability.

-

if (isSmallPicture) {

Danfoss DrivePro® services make success extra sweet

Danfoss DrivePro® services make success extra sweetUptime is critical for the Rajarambapu co-operative sugar factory. DrivePro® services help maintain it.