Extend the life of your AC drives

DrivePro® Preventive Maintenance consists of regular inspections and time interval component replacement according to the product-specific maintenance schedule based on an on-site audit of your installation, environment, and load profile.

The maintenance plan is custom designed to suit specific AC drive types, AC drive system demands, and environmental challenges per installation. Tailored plans can be created by measured values for environment conditions, current loading, and customer application. Installation and environment conditions are recorded at each maintenance inspection for variations. Customers will receive report recommendations after each inspection for further service actions if required or changes to the maintenance plan based on variations to environment, load, line power, process control, aging, or customer use to ensure trouble-free operation and long life of the AC drive.

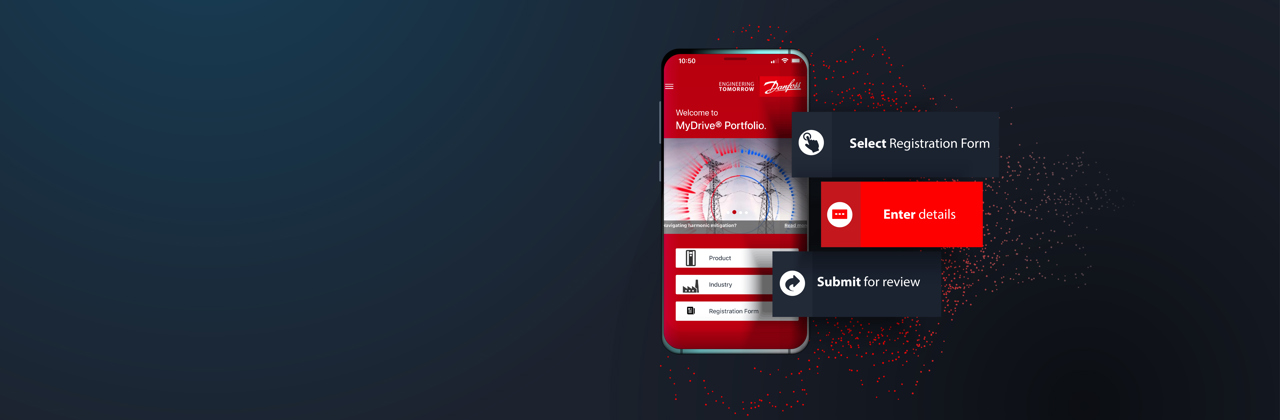

How it works

Features and benefits

Prevent unexpected issues by systematically ensuring the optimal condition of the AC drive

- Improved availability

Reduce the effects of wear and tear

- Extend the drive lifetime

Avoid reactive maintenance and reactive spare parts costs through tailored maintenance program

- Predictable cost saving long-term maintenance plan

- Avoid complexity and take the guess work out of your maintenance plan

Original equipment

- World’s most reliable AC drive components, with TS 16949 approval

- 100% compatibility and durability

- Best protection for your other equipment

FAQ

Case studies

-

if (isSmallPicture) {

Site assessment secures maximum uptime for K+S

Site assessment secures maximum uptime for K+SGERMANY: Thanks to DrivePro® Life Cycle Services, a K+S potash mine got more uptime and a quick retrofit resulting in a better bottom line.

-

if (isSmallPicture) {

Bringing clean drinking water to rural Kenya with 100% renewable resources

Bringing clean drinking water to rural Kenya with 100% renewable resourcesA solar-powered desalination plant in Kenya gives the community affordable, clean, and sustainable drinking water and irrigation water.

-

if (isSmallPicture) {

Hospital selects DrivePro® programs to keep costs down, maintain efficiency

Hospital selects DrivePro® programs to keep costs down, maintain efficiencyAs the largest regional medical center in San Joaquin County, St. Joseph’s Medical Center in Stockton, Calif., has 359-beds, employs over 400 physicians and more than 2,400 employees. Operating the HVAC mechanical equipment for a facility this large is a huge energy-conservation challenge. That's why St. Joseph’s made the decision to use variable frequency drives (VFDs) on HVAC pump and fan motors —a decision that continues to pay off today, thanks to an innovative upgrade plan using Danfoss VLT® Drives.

-

if (isSmallPicture) {

Coca-Cola FEMSA enjoys more uptime with DrivePro®

Coca-Cola FEMSA enjoys more uptime with DrivePro®Since investing in DrivePro® services, the bottling lines at Coca-Cola FEMSA in Brazil have dramatically improved in reliability and availability.

-

if (isSmallPicture) {

Danfoss DrivePro® services make success extra sweet

Danfoss DrivePro® services make success extra sweetUptime is critical for the Rajarambapu co-operative sugar factory. DrivePro® services help maintain it.