About inverter technology for AC, heating and ventilation

A quantum leap in energy efficiency

The HVAC market is rapidly changing. Inverter technology is the most energy efficient technology and is currently revolutionizing the way air conditioning systems are being designed and built to meet climate control needs around the world. The first to embrace variable-speed technology gains a competitive advantage.

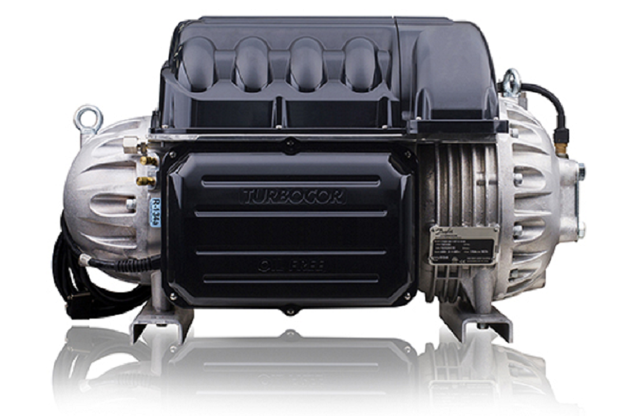

Market needs: Avoid system oversizing, reduce electricity bill and inrush current, increased comfort and process are some key drivers for variable capacity.

Modulating technologies: There are several ways to modulate the cooling capacity in refrigeration or air conditioning and heating systems.

Bypass method

Working principle: Inverter compressors operate at different speeds generating a modulated refrigerant mass oil flow and cooling output.

Benefits: Better power supply quality, system diagnostics, humidity control, energy savings, accurate temperature control, less noise, process safety, greater comfort

Challenges: Compressor and drive selection, designer skills makes the system overall reliability and efficiency.

Danfoss variable speed technology

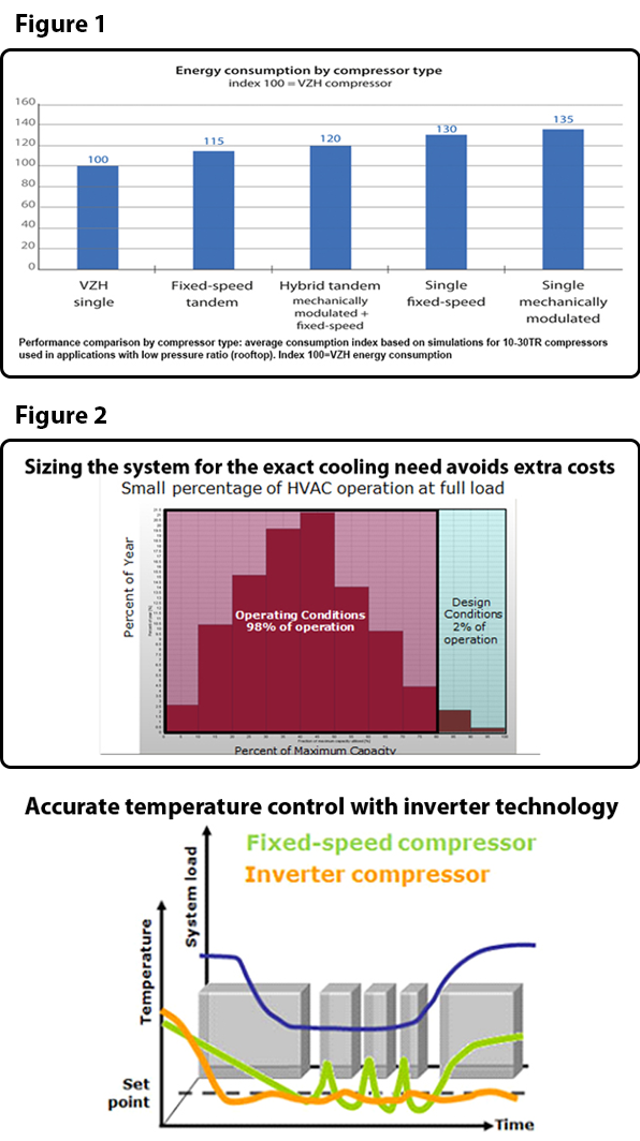

By using the Danfoss inverter compressor solutions, significant energy savings can be achieved compared to traditional on-off compressors or mechanically-modulated technologies.

Products

-

if (isSmallPicture) {

Reciprocating inverter - VTZ

Reciprocating inverter - VTZDanfoss reciprocating inverter compressors avoid oversized and short cycling systems. The compressor automatically adapts to the current load. By combining an efficient Danfoss Maneurop® reciprocating compressor with a Danfoss Drive, we provide an innovative and intelligent package that utilizes variable-speed technology to ensure superior efficiency across the entire operating range for precision cooling.

-

if (isSmallPicture) {

Variable-speed inverter scroll compressors

Variable-speed inverter scroll compressorsDanfoss inverter scroll compressors for commercial air conditioning use variable-speed technology to deliver the highest possible cooling capacity and energy efficiency.

-

if (isSmallPicture) {

Turbocor® - TTS

Turbocor® - TTSDanfoss Turbocor® model TTS oil-free compressors are available in four different models ranging from 60 tons to 200 tons / 200 to 700 kW utilizing R134a or low GWP R513A.

-

if (isSmallPicture) {

Turbocor® - VTT

Turbocor® - VTTDanfoss Turbocor® model VTT oil free compressor is available with a capacity up to 400 tons / 1430 kW using R134a. This compressor is designed for water and evaporative cooled chiller applications.

-

if (isSmallPicture) {

Turbocor® - TGS

Turbocor® - TGSDanfoss Turbocor® model TGS oil free compressors are available in 5 different models ranging from tons to 150 / 140 kW to 540kW utilizing ultra-low GWP R1234ze or R515B.

Related applications

-

if (isSmallPicture) {

Air dryers

Air dryersAt Danfoss we have all the refrigeration solutions, experience and know-how to act as a competent and trustworthy partner for the global air drying industry.

-

if (isSmallPicture) {

Drives for Marine Electrification

Drives for Marine Electrification

Learning

Case studies

-

if (isSmallPicture) {

Free-Cooling System Provides Big Returns for Schoeneck Containers

Free-Cooling System Provides Big Returns for Schoeneck ContainersFounded in 1972, Schoeneck Containers is a leading manufacturer of plastic containers for a variety of industries, including food, beverage, personal care, household and industrial products. The company’s flagship facility in New Berlin, Wisconsin, is approximately 180,000 square feet with over 30 production lines producing over 300 million containers annually.

-

if (isSmallPicture) {

CaptiveAire and Danfoss Improve Indoor Air Quality with Variable-Speed Dedicated Outdoor Air Systems (DOAS)

CaptiveAire and Danfoss Improve Indoor Air Quality with Variable-Speed Dedicated Outdoor Air Systems (DOAS)According to the U.S. Centers for Disease Control, reducing exposure to and spread of COVID-19 should take layered approach that includes increased outdoor air flow and improved ventilation. This is because indoors, viral particles spread more easily and are more likely to be in greater concentration compared to outdoors where the air moves and reduces them more freely.

-

if (isSmallPicture) {

Denmark's new climate-friendly hospitality giant depends on Turbocor® oil-free chiller

Denmark's new climate-friendly hospitality giant depends on Turbocor® oil-free chillerThe new Alsik hotel in Southern Denmark sets a higher standard in energy-efficiency and is built to reach 76% CO₂-neutrality. A main contributor is the 900-kW chillers by Clint (a company of G.I. Industrial Holding) which features award-winning Danfoss Turbocor oil-free compressors.

-

if (isSmallPicture) {

Oil-free compressors maintain consistent performance over time

Oil-free compressors maintain consistent performance over timeDanfoss conducted a study to see how long term operation affected performance on Danfoss Turbocor® compressors. The results showed that oil-free, magnetic bearing compressors maintained consistent performance even after 10+ years of operation.

-

if (isSmallPicture) {

Utility’s Growth Fueled by VFD's

Utility’s Growth Fueled by VFD'sManagement of water and wastewater is a major issue in the central highlands of Arizona, which gets only about 12 inches of precipitation a year. To handle growing water demands, the City devised a strategic water management plan that included creating a modern municipal water system with effective monitoring, control and pumping technology – a development made possible by Danfoss variable frequency drives (VFDs).

-

if (isSmallPicture) {

VLT® Micro Drives help Vermont small businesses boost efficiency for rooftop HVAC

VLT® Micro Drives help Vermont small businesses boost efficiency for rooftop HVACVFDs are used for a wide range of motors, not just RTU fan motors. Danfoss was able to pre-program the VLT® Micro Drive specifically for RTU applications and offer it to contractors. Because the programming work is done upfront, the contractor simply mounts the drive inside the RTU, wires it up, and enters the nameplate installation. Most mechanical contractors can do the job in about half a day.

News

-

Enhanced VLT® AutomationDrive EZ FC 321: New Features Set a New Standard for Industrial EfficiencyFriday, November 1, 2024

Danfoss is proud to announce the latest enhancements to the VLT® AutomationDrive EZ FC 321, a leading solution in the field of low-voltage drives with embedded Condition-Based Monitoring.

-

if (isSmallPicture) {

Coolselector®2: We did complex. You do awesome.Wednesday, March 20, 2019

Coolselector®2: We did complex. You do awesome.Wednesday, March 20, 2019Coolselector®2 is essential software for engineers, consultants, and system designers who work in the refrigeration and air conditioning industry. Using Coolselector®2, you can easily optimize energy consumption and increase efficiency in your HVACR system — simply run calculations based on your operating conditions and then choose the best component setup for your design.

-

if (isSmallPicture) {

VLT® HVAC Drive joins exclusive company of 1000 Efficient Solutions globallyTuesday, July 17, 2018

VLT® HVAC Drive joins exclusive company of 1000 Efficient Solutions globallyTuesday, July 17, 2018How does reduction of methane production in beef cattle and the transformation of biogas into clean fuel for heavy vehicles link to efficient buildings enabled by Danfoss? They are all endorsed by the World Alliance for Efficient Solutions.

Contact us

For further information, please contact us.