Efficient performance

Danfoss continues to lead the industry with groundbreaking fan drive technologies like our reverse displacement motor (RDM). By occasionally changing the airflow direction, accumulations of debris can be dislodged from the vehicle’s radiator. This helps to ensure efficient cooling system performance.

When used in radiator cooling fan applications, the Danfoss RDM uniquely incorporates the external shift valve within the motor itself. This is eliminating the directional control valve, and either simplifying or completely eliminating the HIC block. With fewer components in the hydraulic circuit, the RDM frees up space in the engine compartment. This creates additional opportunities for innovation.

Design advantages like this help combat the challenges brought on by today’s harder-working, hotter-running Tier 4-compliant engines. Places where emission control equipment takes up more under-hood space than ever before. Building on our proven efficiency and reliability, the compact Danfoss RDM motor is technology that’s helping Danfoss engineer tomorrow.

Danfoss offers a wide range of efficient fan drive systems. Below are the benefits and critical considerations. You need to take these into account as you determine the right system for your specific needs.

Benefits

Increased efficiency due to variable flow and piston motor technology

Fan speed independent of engine speed

Fails to full fan speed

Motor speed sensors available

Higher motor pressure, power and life ratings

Less engine power consumption

Critical considerations

Back pressure required for axial piston motors

No ZERO speed capability

Larger reservoir capacity required for high flows

Motor thrust load capability must be calculated

Related products

Coming soon...

Coming soon...

Related solutions

-

if (isSmallPicture) {

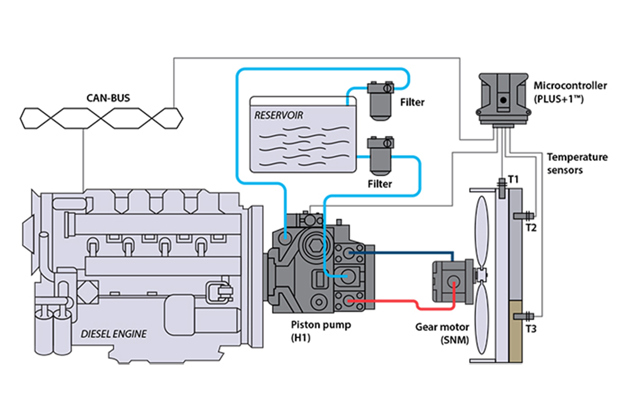

Closed circuit pump w/ gear motor (reversible

Closed circuit pump w/ gear motor (reversibleDanfoss offers a wide range of efficient fan drive systems. Explore more about the benefits and the critical considerations you need to consider as you determine the right system for your specific needs.

-

if (isSmallPicture) {

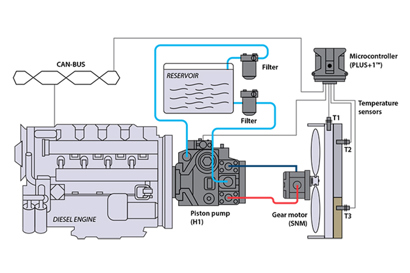

Closed circuit pump w/ piston motor (reversible)

Closed circuit pump w/ piston motor (reversible)Danfoss offers a groundbreaking fan drive technologies, such as the closed circuit pump w/ piston motor (reversible).

-

if (isSmallPicture) {

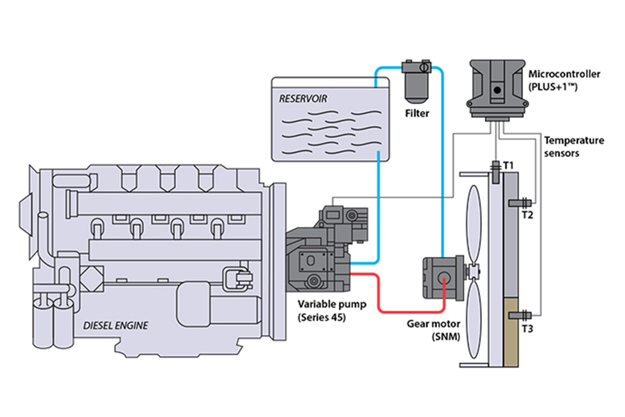

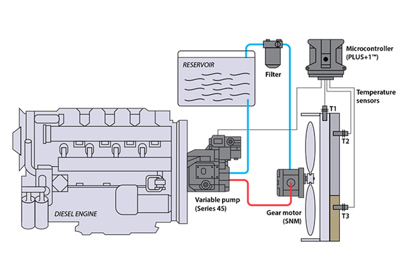

Variable displacement open circuit pump w/ gear motor (non reversing)

Variable displacement open circuit pump w/ gear motor (non reversing)Danfoss offers a wide range of efficient fan drive systems.

-

if (isSmallPicture) {

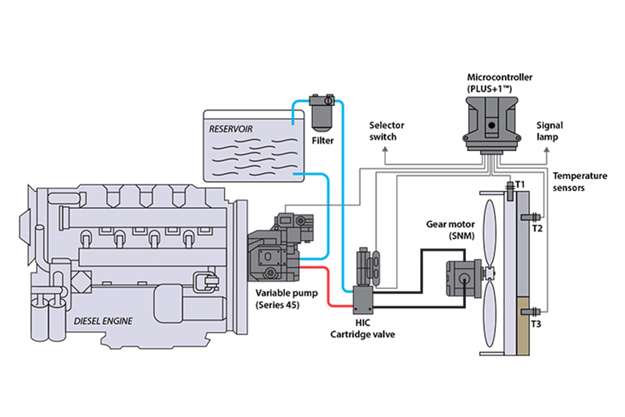

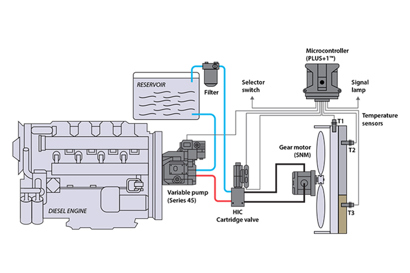

Variable displacement open circuit pump w/ gear motor (reversing HIC)

Variable displacement open circuit pump w/ gear motor (reversing HIC)Danfoss offers a groundbreaking fan drive technologies, such as the variable displacement open circuit pump w/ gear motor (reversing HIC).

-

if (isSmallPicture) {

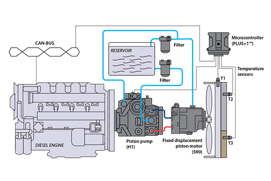

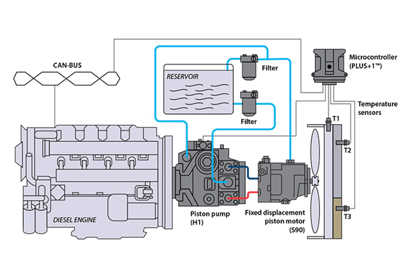

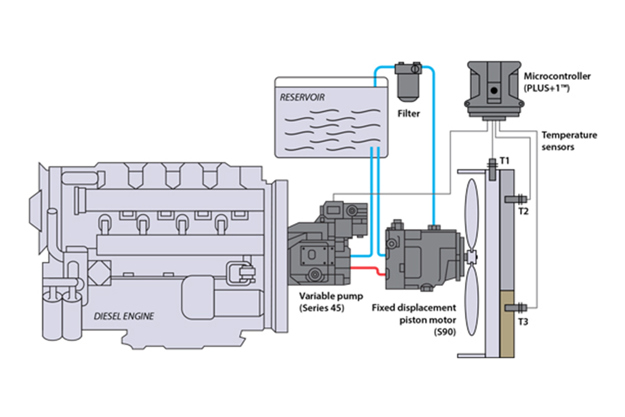

Variable displacement open circuit pump w/ piston motor (non reversing)

Variable displacement open circuit pump w/ piston motor (non reversing)Danfoss offers a wide range of efficient fan drive systems based on your unique cooling needs. we can work with you to design a number of different open circuit and closed circuit fan drive systems. Helping to solve your challenges.