Safe and reliable solutions for the chemical and petrochemical industry

Products from the chemical and petrochemical industry make modern life easy. These industries pose some of the strictest requirements to handling and treatment of substances like oil, gas, and a large variety of chemical compounds. Efficient supply, refining and transportation of the valuable raw materials kept at accurate temperature levels at all times can be achieved with refrigeration solutions from Danfoss.

The specifications for refrigeration in the chemical and petrochemical industries are rigid. Only approved products for certain pressure ranges and harsh environments can be used. The Danfoss products for the chemical and petrochemical industry represent high levels of reliability and safety, a long service life and high performance and energy efficiency.

To learn more about Danfoss products for the chemical and petrochemical industry please contact your local Danfoss representative.

Features and benefits

Precise temperature control

Reliable solutions, low operation and maintenance costs

High performance and high energy efficiency

Documents

| Type | Name | Language | Valid for | Updated | Download | File type |

|---|---|---|---|---|---|---|

| Application guide | Application Handbook - Automatic Controls for Industrial Refrigeration Systems | English | Multiple | 27 Mar, 2025 | 18.5 MB |

Related products

-

if (isSmallPicture) {

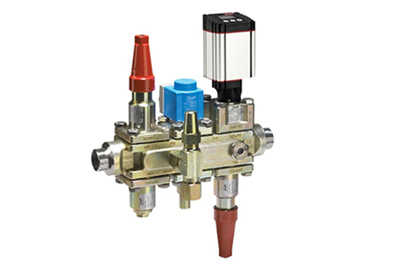

ICF Flexline™ valve station

ICF Flexline™ valve stationUnmatched freedom is the keyword of ICF Flexline™ valve stations. As part of the Flexline™ platform, these valve stations are based on a unique modular concept.

-

if (isSmallPicture) {

SVL stainless steel

SVL stainless steelThe range of stainless steel products is based on the successful modular concept from the products in the Flexline™ family, covering the SVL valves. The stainless steel products are therefore offer many of the same benefits known from the Flexline™ concept.

-

if (isSmallPicture) {

SVL 52 bar Flexline™

SVL 52 bar Flexline™The SVL Flexline™ 52 Bar product platform is targeted to meet industrial refrigeration requirements worldwide.

-

if (isSmallPicture) {

SVL-140B Flexline™

SVL-140B Flexline™SVL Flexline™ platform is expanded to 140 bar MWP to meet an increasing demand of large manual valves in industrial design for large scale R744 transcritical CO2 systems.

-

if (isSmallPicture) {

ICM Flexline™ motor valves

ICM Flexline™ motor valvesICM motor-operated valves, part of Danfoss' ICV Flexline™, regulate the expansion process in liquid lines and control pressure or temperature in wet and dry suction lines and hot gas lines. Compact and lightweight, ICM valves are easy to handle, install, and service.

Contact us

For further information, please contact us.