Ensure your positioning and synchronization are precise and cost-effective

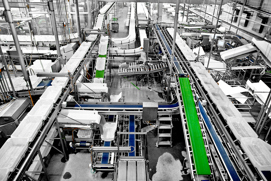

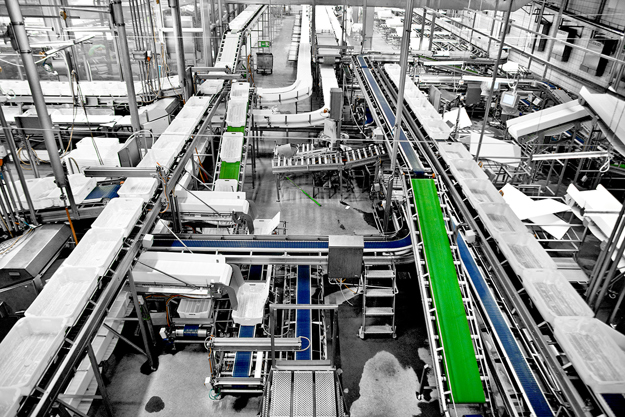

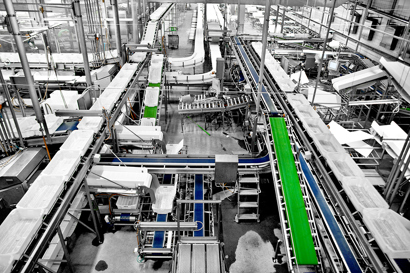

To optimize performance, many applications in the Food and Beverage industry, such as conveyors, palletizers and packaging machines, have a need for precise positioning and synchronization.

To date, positioning and synchronization operations have been performed using servo drives. However, servo equipment is expensive, difficult to commission and requires additional cabling. And many applications do not require the dynamic performance available from a servo drive.

The Danfoss Drives Integrated Motion Controller (IMC) is functionality configurable in the software of the VLT® AutomationDrive FC 302 that enables an AC drive to perform high-precision positioning and synchronization operations without the need for additional modules or hardware.

Advantages of IMC

- Reduced costs and system complexity

- Works with all conventional motor technologies with closed loop or open loop control with no need for additional hardware

- No need for the complex programming required for many servo drives

- Drives are adapted to applications through simple parameterization

- Sensorless homing with torque detection

- In many cases no need for encoder feedback

Perfection in positioning and synchronization

The new, optional Integrated Motion Controller (IMC) makes VLT® AutomationDrive FC 302 different. Thanks to the IMC functionality, the VLT® AutomationDrive FC 302 is now a competitive performer in positioning or synchronizing applications - with no additional hardware modules required.

Products

-

if (isSmallPicture) {

VLT® AutomationDrive FC 301 / FC 302

VLT® AutomationDrive FC 301 / FC 302The VLT® AutomationDrive FC301 / FC302 is designed for variable speed control of all asynchronous motors and permanent magnet motors. It comes in a standard version (FC301) and an advanced high dynamic version (FC302) with additional functionalities.

Case studies

-

if (isSmallPicture) {

Future-proof energy efficiency at AB InBev Hoegaarden® brewery

Future-proof energy efficiency at AB InBev Hoegaarden® breweryChallenged by aging machinery and no time for downtime, AB InBev Hoegaarden® chose Danfoss iC7-Automation and VLT® OneGearDrive®—for high energy efficiency.

-

if (isSmallPicture) {

Danish Crown super slaughterhouse saves 37k USD annually on motor replacement

Danish Crown super slaughterhouse saves 37k USD annually on motor replacementThe 1,000 VLT® drives installed throughout the plant control everything from simple conveyor belts to more advanced applications.

-

if (isSmallPicture) {

Powder mixing productivity triples with wireless PROFINET

Powder mixing productivity triples with wireless PROFINETTriple the throughput and decimate the downtime? That’s what the Dutch powder mix provider, Huijbregts Groep, achieved by automation of mixers using VLT® AutomationDrive with wireless PROFINET.

-

if (isSmallPicture) {

Traditional brewery engineers tomorrow

Traditional brewery engineers tomorrowSince upgrading its filling plant to energy-efficient drives from Danfoss, Stiegl Brewery of Salzburg saves about EUR 15,000 annually in maintenance and energy consumption.

-

if (isSmallPicture) {

Improved process control for Valio

Improved process control for Valio100 VACON® 100 drives enable accurate control of production line and improve work safety and reliability.

-

if (isSmallPicture) {

Up to 63% energy savings for Efes Pilsen

Up to 63% energy savings for Efes PilsenReplacing old gear motors on the conveyor lines with VLT® FlexConcept® which incorporates VLT® OneGearDrive® has helped Efes Pilsen work towards their operational efficiency and sustainability targets.