A unique supermarket

On June 29th the COOP 365 Smart Store opens for the public for the first time. In the Danfoss Smart Store the cooling and heating technologies are in operation 24/7. It’s not a laboratory simulating real-life operation. Customers open cabinet doors hundreds of times a day and every time it puts demand on the cooling and heating of the supermarket. The Danfoss Smart Store demonstrates our available solutions in action.

BALS, Brugsforeningen for Als and Sundeved, Denmark’s largest independent supermarket association, will rent the building from Danfoss and will install a COOP 365discount supermarket. BALS, which works together with COOP, has a total of 13 stores in the area around Sønderborg in Denmark and since 2015 has consistently reduced the consumption of energy in its stores. So far, they have cut 44 percent of their total CO2 emissions. Therefore, it was a natural next step that BALS became a partner in the project.

Lars G. Andersen, managing Director of BALS, says:

“We already have a lot of experience, but the energy price spikes have put further pressure on the need for change. Our 13 supermarkets have been modernized, and we have nearly no cost for heating in the stores because the heat comes from our freon-free refrigeration systems, solar cells, and heat pumps. It is an advantage with the current energy prices, and it reduces our CO2 emissions. We are proud to be part of one of the most energy-efficient supermarkets in the world and test the solutions that can help buildings become climate neutral.”

Danfoss builds supermarket

Ground-breaking ceremony for the construction of one of the world’s most energy-efficient supermarkets.

Scalable technologies

The installations and technologies in the supermarket are scalable. They can be applied in the smallest store up to the biggest hypermarket.

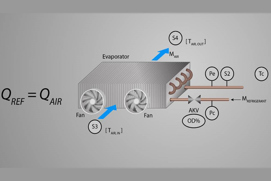

The supermarket cooling (refrigeration and comfort cooling) systems run exclusively on natural refrigerants (CO2). CO2-based refrigerants do not deplete the ozone layer and have the lowest possible Global Warming Potential (GWP) score. In addition, CO2 refrigerants outperform traditional HFC-systems when it comes to energy efficiency in different weather conditions.

The supermarket is equipped with a heat recovery unit capturing excess heat from the cooling systems to provide space heating for the entire store as well as the surrounding community through the district heating network. The heat recovery unit, can by re-using the excess heat from the cooling system, reduce the external heat requirement with up to 89,7%. Furthermore, the energy pack can supply additional heating and cooling when needed.

Smart energy systems applied

100 KW solar panels on the roof help to optimize store operations. On sunny days, solar energy can be accumulated in the freezers. Turning the temperature in the freezers further down from e.g., -18 to -25 help accumulate solar energy ( while reducing battery storage). When the solar panels are less efficient due to no sun the temperature rises back to normal settings.

Co-developing with customers

The supermarket has two separate refrigeration systems installed that run independently of each other. Therefore, operations of a supermarket continue while Danfoss co-develops new solutions with customers. And when future applications are being tested, the cooling cabinets and freezers stay cool.

Certifications

DGNB Gold (EU)

LEED Platin (USA)

The final certifications can only be obtained after six months of operations.

The Smart Store provides inspiration for building DGBN / LEED certified supermarkets showcasing that it does not require a lot of extra resources to ensure that the building is healthy, future proof, and positively impacting the surrounding community.

Biodiversity

In order to positively impact the local biodiversity several initiatives have been taken. Very visible mega pergola surrounding the building which will be watered by use of collected rain- and surface-water. Also, different native grasses as well as a ‘green roof’ will be planted to create a micro-environment for biodiversity.

Cooling and heating capacity for 1,500 m2 store and 250 m2 ADC

30 kW medium temperature

13 kW freeze - low temperature

20 kW comfort cooling/ventilation for store and ADC (additional 20 kW from roof-top chiller)

Highlighted products

-

if (isSmallPicture) {

CCMT electric regulating valves, transcritical CO₂

CCMT electric regulating valves, transcritical CO₂The CCMT is an electric operated valve designed specifically for operation in CO2 systems. The valve is capable of functioning either as an expansion valve, as a pressure regulator for the gas cooler or as a gas bypass valve with back-pressure regulation in trans-critical or subcritical applications.

-

if (isSmallPicture) {

System managers

System managersThe system manager is the key component of the intelligent Danfoss ADAP-KOOL® refrigeration system for food retail.

-

if (isSmallPicture) {

Programmable controllers - MCX

Programmable controllers - MCXDanfoss’ range of universal MCX programmable controllers offers the functionality and reliability you need to get the best out of your heating, ventilation, air-conditioning and refrigeration (HVAC/R) equipment.

-

if (isSmallPicture) {

Compressor and condenser controllers

Compressor and condenser controllersDanfoss offers a range of compressor and condenser capacity controls for use in food retail, in compact systems as well as in large power packs.

-

if (isSmallPicture) {

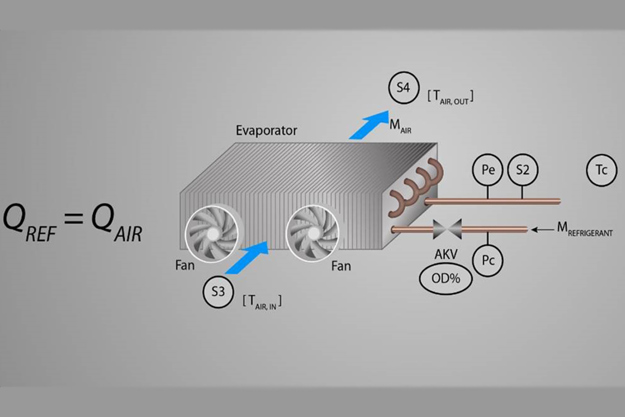

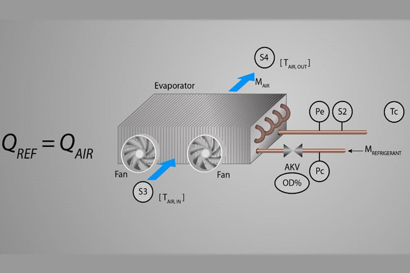

AKV electric expansion valves

AKV electric expansion valvesAKV are electrically operated expansion valves designed for refrigerating plants. The AKV valves are normally controlled by a controller from Danfoss’ range of ADAP-KOOL® controllers.

-

if (isSmallPicture) {

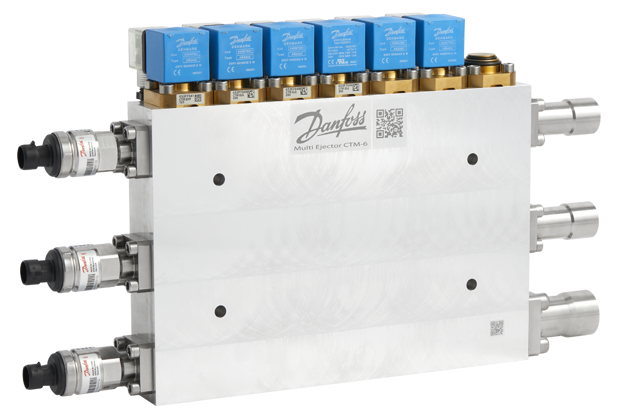

Multi Ejector Solution™

Multi Ejector Solution™The Danfoss Multi Ejector Solution™ ensures that transcritical CO₂ applications for retailers become energy efficient in any climate.

-

if (isSmallPicture) {

Evaporator and room control

Evaporator and room controlDanfoss offers a range of evaporator controls with thermostatic expansion valves or with electric expansion valves.

-

if (isSmallPicture) {

Refrigeration temperature sensors

Refrigeration temperature sensorsRefrigeration temperature sensors are used for applications within air-conditioning as well as commercial and industrial refrigeration applications. The Pt 1000 sensor element meets the DIN/IES 751 class B requirements and ensures an accurate and reliable temperature signal applicable for regulation, safety and data logging.

-

if (isSmallPicture) {

Air conditioning & refrigeration pressure transmitters

Air conditioning & refrigeration pressure transmittersRefrigeration pressure transmitters are used for commercial air-conditioning and for commercial and industrial refrigeration applications. They are made in stainless steel to be compatible with fluorinated and natural refrigerants and laser welding with no soft seals ensure hermetic tightness for decades.

Related applications

-

if (isSmallPicture) {

Case controls

Case controlsYour refrigeration system is the natural place to look for energy efficiency gains. To unlock that potential, you need a controller, expansion valve, and high accuracy sensors that are smart enough to make the technology work together—and a system manager that can help you see and control the bigger picture.

-

if (isSmallPicture) {

CO₂ in supermarkets

CO₂ in supermarketsDanfoss has pioneered CO₂ refrigeration systems for more than 10 years. Learn more about our CO₂ refrigeration solutions for supermarkets here.

-

if (isSmallPicture) {

Condition monitoring of HVAC/R systems

Condition monitoring of HVAC/R systemsIn air flow and indoor air quality-related applications, condition monitoring functionality improves system uptime and competitiveness by preventing issues before they occur.

-

if (isSmallPicture) {

HVAC integration in supermarkets

HVAC integration in supermarketsAlign your heating, ventilation, air conditioning, and refrigeration systems, to save money, safeguard stock, and reduce your environmental impact. Integrated solutions unlock the full potential of each application and increases the efficiency of the entire system.

-

if (isSmallPicture) {

Monitoring and management

Monitoring and managementConnecting your refrigeration system to the cloud offers a world of possibilities to save money and improve food safety. Remote monitoring and management make it easy to check and triage system alarm.

-

if (isSmallPicture) {

Smart energy

Smart energyEnergy cost is one of the biggest expenses in the daily operation of your supermarkets. Therefore, retailers increasingly look to enhance the energy efficiency within the stores.

Case studies

-

if (isSmallPicture) {

A cranberry producer in Quebec, Canneberges Drummond Inc., modernizes its pumping system and reduces its carbon footprint with Danfoss solutions

A cranberry producer in Quebec, Canneberges Drummond Inc., modernizes its pumping system and reduces its carbon footprint with Danfoss solutionsCanneberges Drummond Inc. recently completed a major modernization of their pumping system, transitioning from diesel to an eco-friendly, automated solution—thanks to the collaboration of Kopers and 6MGB. By integrating Danfoss VLT® AQUA Drive FC 202, MCT 31 Harmonic Calculation Software, and the VLT® Advanced Harmonic Filter, the cranberry producer achieved: reduced CO2 emissions, improved system reliability, lower operational costs.

-

if (isSmallPicture) {

CO₂ Chillers Give Pro-Refrigeration A ‘Future-Proof Solution’

CO₂ Chillers Give Pro-Refrigeration A ‘Future-Proof Solution’With the approaching HFC phasedown, the demand for environmentally friendly cooling systems is driving chiller manufacturers to innovate. Washington-based Pro Refrigeration, Inc., a leading manufacturer and supplier of chillers for the industrial and beverage processing market, including the dairy, beer and wine industries, recognized an opportunity with CO₂ chillers.

-

if (isSmallPicture) {

The secret behind Danfoss adaptive defrost

The secret behind Danfoss adaptive defrostBefore digging into the secret of Danfoss adaptive defrost, let’s first take a look at the most common methods of defrosting refrigerated display cases, and why they’re necessary.

-

if (isSmallPicture) {

Engineering Tomorrow helps transform supermarkets into “Smart Stores” for demand response

Engineering Tomorrow helps transform supermarkets into “Smart Stores” for demand responseLike any supermarket chain, Giant Eagle operates in a very competitive marketplace where energy management can be a crucial ingredient to success and profitability. That’s why the Pittsburgh, Pennsylvania-based chain carefully manages its stores’ critical energy consumers: lighting, refrigeration, and HVAC equipment. When Giant Eagle learned its utility—PJM Interconnection—offered a demand response program that provided incentives to reduce electric consumption, they talked to Danfoss to see how they could take advantage of the opportunity.

-

if (isSmallPicture) {

Engineering Tomorrow allows environmentally-focused retailer to achieve its goals

Engineering Tomorrow allows environmentally-focused retailer to achieve its goalsLooking to evolve its refrigeration strategy to anticipate evolving refrigerant regulations and reduce cost, supermarket chain Weis Markets partnered with Danfoss to slash the global warming potential of its refrigeration systems by deploying its first transcritical CO2 refrigeration system.

-

if (isSmallPicture) {

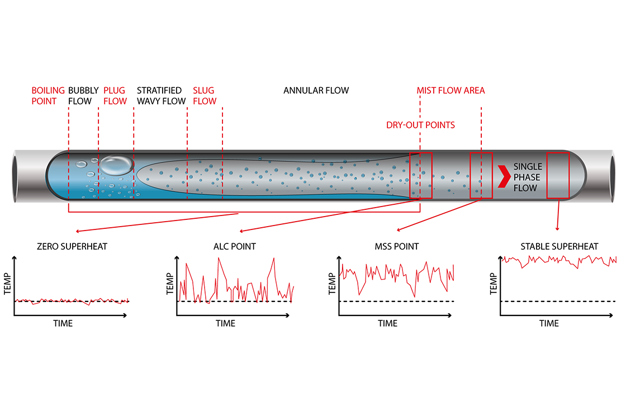

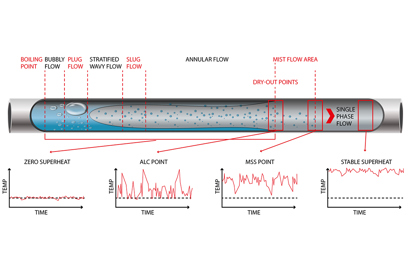

Selecting the right evaporator injection algorithm makes a world of difference

Selecting the right evaporator injection algorithm makes a world of differenceDanfoss has pioneered two control algorithms that help you achieve this balance. The Minimum Stable Superheat (MSS) algorithm has been an important part of the Danfoss ADAP-KOOL® offering for years and is still the ideal choice for adaptive evaporator control for dry expansion. Now Danfoss introduces the next generation: Adaptive Liquid Control (ALC).

Contact us

Want to experience real supermarket efficiency?

Reach out to us if you are interested in visiting our SM ADC and see real live.