Welcome efficiency. Welcome electric.

The electrification megatrend will increase electricity demand by 150%. To prepare, the EU has therefore set a target of 40 GW electrolyzer capacity by 2030, equivalent to approximately 200 TWh electricity consumption. Hydrogen is the bridge between renewable electricity and hard-to-decarbonize sectors, which can help society meet this electricity demand, sustainably.

Enabling a future powered by electricity

To achieve an electrified world, industry requires solutions that maximize energy efficiency from renewable sources when capacity is high and convert into firm clean energy for use when capacity is low. That requires high efficiency power conversion with low harmonic distortion while ensuring global scalability and cost-effectiveness.

In its pure form, hydrogen can be used to replace fossil fuels in some industries. To e-fuel even more industry, the hydrogen can be synthesized into e-methanol, e-ammonia, or e-diesel. By converting to these sustainable energy sources, we can reduce reliance on fossil fuels.

Source: Adapted from Ørsted & EU data, approximate numbers

Electrification of energy consuming sectors is vital for decarbonization

Our ambition is to help you achieve your electrification goals. Because together we can create a sustainable future powered by electricity. As a world leader in electrification as well as in heating and cooling solutions, we here at Danfoss are always thinking holistically on topics such as Power-to-X. Coupled with state-of-the-art co-development facilities and an inherent engineering mindset, our employees are always eager to share their knowledge to find the best solution to the challenge at hand. With a core focus on energy efficiency and system effectiveness, Danfoss is ideally placed as your expert partner in Power-to-X, both technically and commercially.

Recognized world-wide as a reliable supplier, Danfoss adheres to the highest international standards in production and development quality. With Danfoss solutions you get proven competitiveness and reliability, to get your business on target for a decarbonized economy.

Contact our experts

Ready to get started?

Are you ready to accelerate your electrification journey? Our Power-to-X expert, Cliff Stokes, is ready to get in touch with you and have an informal discussion.

Learn more

Stay up to date with Danfoss Drives

-

if (isSmallPicture) {

Danfoss to showcase reliable, energy-efficient solutions for data centers at SuperComputing 2025Wednesday, October 29, 2025

Danfoss to showcase reliable, energy-efficient solutions for data centers at SuperComputing 2025Wednesday, October 29, 2025Danfoss will exhibit its broad portfolio of technologies that increase data center uptime and reliability at SuperComputing 2025, November 18-20, in St. Louis, Missouri. At booth 2237, Danfoss will showcase its high-performance HVAC components, fluid conveyance products for liquid cooling systems, variable frequency drives, and other power distribution solutions under the theme, “You run the data. We keep it cool.”

-

if (isSmallPicture) {

Find the right drive with Danfoss DriveFinder | VFD selection toolWednesday, October 15, 2025

Find the right drive with Danfoss DriveFinder | VFD selection toolWednesday, October 15, 2025Need to find the right variable frequency drive (VFD) for your application? Then try Danfoss DriveFinder. With a few simple questions, this tool helps you find the best drive for the task, as well as a trusted supplier.

-

Early detection, lasting protection: Sine-wave filter monitoringMonday, September 1, 2025

Danfoss introduces DrivePro® 360Live: the ultimate data-driven asset management solution designed to transform maintenance practices and empower marine and industrial teams with unparalleled visibility, control, and efficiency.

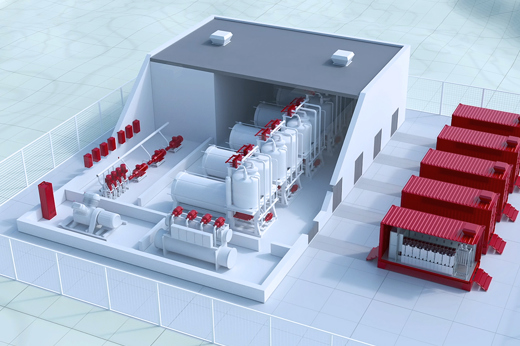

Our approach

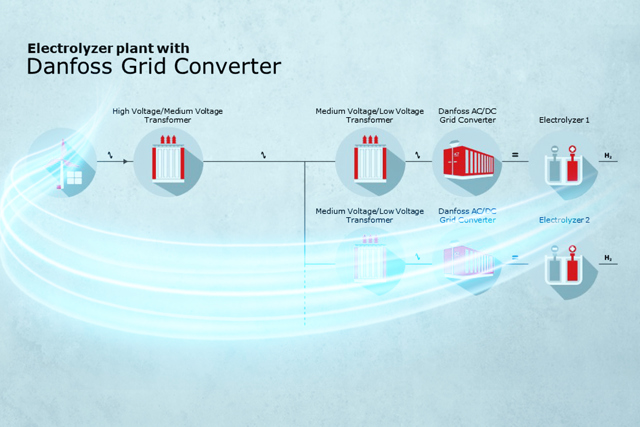

At Danfoss, we help you think beyond the system itself. By taking a holistic perspective on the entire ecosystem, we secure energy efficiency and system effectiveness that is both scalable and economically viable. With extensive expertise in Power-to-X systems and electrolysis, we tailor the solution to your specific needs. That way you get a plug-and-play system with maximum performance that evolves alongside your operations, at your pace. Danfoss technology has been developed and refined to deliver future-proof, guaranteed performance with many added features to lower risk and ensure a stable operation. You achieve better total economy and peace of mind for operational excellence of your electrolysis plant. Danfoss will provide you a grid-friendly, approved solution with impressive energy efficiency. Low harmonics and a high power factor ensure that you have a competitive power supply for your electrolyzer at hand. With long experience in power conversion combined with a leading position in the world, Danfoss is your ideal partner for your investment in the hydrogen market.

Where there is energy, there is opportunity

Coupled with state-of-the-art test facilities and an inherent engineering mindset, our employees are always eager to share their knowledge to find the best solution to the challenge at hand. Together with a core focus on energy efficiency, not only in the products we deliver but also holistically in entire systems, Danfoss is ideally placed as an expert partner in Power-to-X.

Recognized world-wide as a reliable supplier, Danfoss adheres to the highest international standards in production and development quality. One example: our drives for power conversion are produced and developed according to the stringent requirements of the automobile industry.