Derag pumps for more uptime

Clogged pumps work less efficiently and use more energy to do their job than clean pumps. If unattended, eventually a clogged pump will grind to a halt, causing unplanned downtime. Therefore, it is unsurprising to find that pump clogging is a costly issue for sewerage systems and wastewater treatment plants. The solution? Deragging functionality in the AC drive can prevent clogged pumps, promote uptime, and cut operating costs.

Prevent clogged pumps with condition monitoring and deragging

There is no need to experience a clogged pump ever again. With the help of intelligent variable frequency drives, it is possible to detect potential clogs early. When detected early enough, operators can derag and clear the debris causing blockage, before it affects the electricity bill or causes downtime. Since the functionality is integrated in the drive, operators achieve reduced installation time. Even more significantly, improved predictive maintenance lowers operating costs and boosts uptime for the wastewater industry.

How does condition-based deragging work?

The technology behind early clog detection and deragging is integrated into intelligent drives from Danfoss. Condition-based monitoring and the deragging functionality act together to support reliable and hassle-free pumping. The combined effect of condition monitoring and deragging is also known as condition-based deragging.

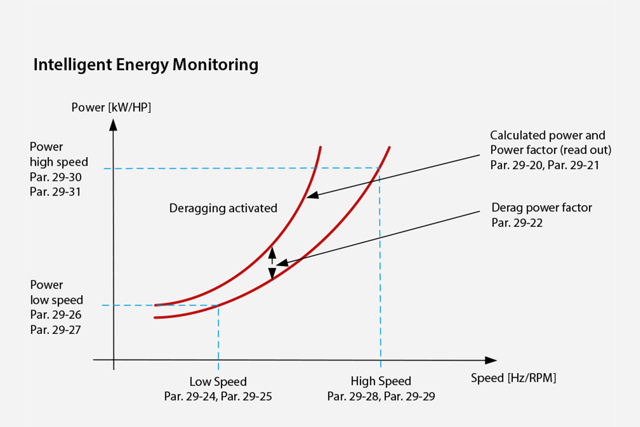

Potential pump clogging is visible in the pump load profile, already at the early stage of partial clogging. Using integrated condition-based monitoring (CBM) the drive raises an alert, giving operators the power to intervene, also known as human-in-the-loop machine learning.

Real-time monitoring detects pump blockage

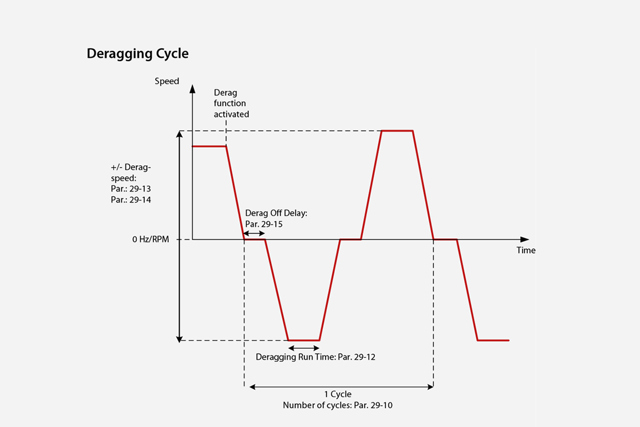

How does the integrated CBM functionality know when a deviation from correct pump operation arises? Cloud-free machine learning embedded in the drive automatically defines operating baseline parameters corresponding to specific applications, at all speeds and real-life operating cycles. Once the baseline is defined and the learning period completed. CBM can detect deviations. Over time, once operators learn how often blockages occur, they can set the deragging function to operate at optimal intervals. Regular deragging intervals are a valuable contribution to the preventive maintenance strategy for pump maintenance.

Clog-free pumping since 2021

Grand Strand Sewer Authority has 769 pumping stations and is adding new ones on a regular basis, so clogging is a significant concern. However since implementing deragging in May 2021, the Authority has experienced no need for manual cleaning or unclogging of its pump systems.

How does CBM optimize pumping?

Take motor and pump supervision to new levels with VLT® AQUA Drive. This video explains how CBM empowers you to act quicky to counteract the effects of clogs, leaks, vibration, and other issues, as part of your predictive maintenance strategy.