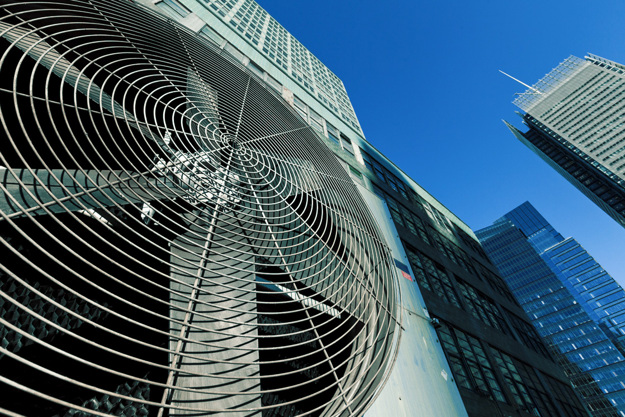

Keep your essential HVAC systems up and running

We are operating in a time of extremes. Whether your facility is ramping up operations to keep up with increased demand, or unexpectedly empty due to a shift to remote working conditions or closures, Danfoss can help you keep your HVAC systems running efficiently so you can focus on business. Our trained experts are here to assess the lifecycle of your equipment, and provide a tailored solution to maximize uptime, efficiency, and savings.

Proven leader in HVAC

AC drives are installed on a daily basis in various heating, ventilation and air conditioning (HVAC) and water-boosting applications in new and existing buildings and infrastructural systems all over the world. They enhance air quality and indoor comfort levels, improve control and energy-saving possibilities, ensure better asset protection, reduce maintenance costs and increase reliability.

The daily load variation in HVAC facilities is considerable. Variable speed control of electrical motors has proved to be one of the most effective cost-reducing measures available. By reducing the average speed of a motor in, for example, a pump or fan by 20%, energy savings of 50% can be achieved. Reducing the average speed by 50% increases the savings to 80%.

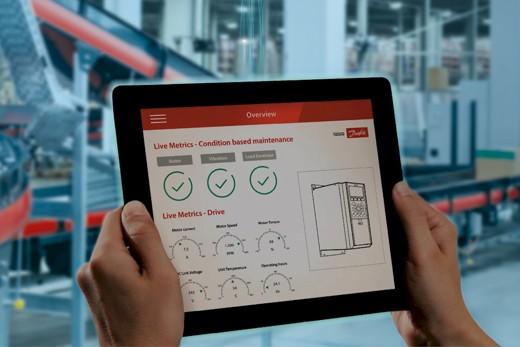

Maximize uptime with Condition Based Monitoring

See how you can turn the frequency drive you already have into the smartest sensor in your system. A sensor that enables predictive and condition-based monitoring (CBM) capabilities, processes data on the edge, and sends data wherever it’s needed. Explore how intelligent drives solve potentially critical problems in HVAC applications.

-

Calculate savings with Energy Box software

Calculate savings with Energy Box software

zipVLT® Energy Box software calculates, as accurately as possible, the cost, savings and payback time of using Danfoss AC drives in HVAC fan and pump applications. The tool allows you to compare the energy consumption of HVAC fans and pumps driven by Danfoss drives with alternative methods of flow control.

Reduce total cost of ownership

Lifetime energy costs have a major impact on total cost of ownership. Even small reductions in energy use can provide vast cost savings over a relatively short timeframe. Seen over its lifetime, the initial cost of an AC drive only amounts to 10% of the total cost of ownership; the remaining 90% covers energy consumption, service and maintenance.

Features, such as Automatic Motor Adaptation and Automatic Energy Optimization, ensure that your drive is always perfectly adapted to the attached motor and changing loads. And, with minimal maintenance requirements, Danfoss AC drives provide a fast return on your HVAC investment and significantly reduce your total cost of ownership.

Applications

HVAC systems regulate the heating and cooling units in a building to provide the highest levels of comfort. The conditions are controlled by several applications which all use AC drives. Here are some of the main HVAC-related applications:

Heating

- Boiler forced and induced draft fans

- Primary hot water pumps

- Fan coils

- Heat recovery systems

Ventilation

- Air handling units, rooftop units, supply and extract fans

- Variable/constant air volume ventilation systems

- Smoke ventilation, fire control and stairway ventilation systems

- Car park ventilation systems

- Kitchen ventilation systems

Cooling

- Chilled water pumping systems

- Primary/secondary pumps

- Variable flow with primary pumps only

- Fan coils

- Heat recovery systems

- Cooling tower fans, Condenser water pumps

- Chiller compressor

Fresh water

- Booster pumps

- Single or parallel pumps

Safety and compliance: Fire and smoke safety

All buildings with requirements for ‘life safety’ on essential service applications require firemode functionality. The fire mode functionality in the VLT® HVAC Drive FC 102 provides reliable and continuous operation of applications related to stairwell pressurization, smoke extraction, lift shaft pressurization and car park ventilation for safer and more effective emergency evacuation. Fire override mode protects the drive in the event of a fire, ensuring vital fan operation regardless of high temperatures, control signals, warnings and alarms.

Seismic compliance

Seismic compliance is essential for all drives running ‘life safety’ applications. The VLT HVAC Drive complies with Importance Factor 1.5. This compliance is tested in accordance with the standard ICC-ES AC-156 by the Californian Office of Statewide Health Planning and Development (OSHPD).

Electromagnetic compatibility (EMC) compliance

Danfoss provides AC drives with optimum EMC protection and integrated harmonic filters to ensure the ideal EMC environment, and cleanest power supplies are maintained throughout the operational lifetime of the system. With first-class EMC compliance, they fulfill the most stringent emission requirements:

IEC 61800-3:2004 Category C1/EN55011 Class B (residential) with 50-meter screened motor cable

IEC 61800-3:2004 Category C2 & C3/ EN55011 Class A Group 1 & Group 2 with 150-meter screened motor cable

Get more information

-

if (isSmallPicture) {

Drives for commercial compressors

Drives for commercial compressorsVariable speed control with AC drives enables you to reduce energy consumption by running compressor applications at a lower speed.

-

if (isSmallPicture) {

Drives for data centers

Drives for data centersFacilitate ideal climate conditions around server installations, while minimizing energy consumption and CO2 emissions.

-

if (isSmallPicture) {

Drives for fans in commercial buildings

Drives for fans in commercial buildingsWith user-friendly interfaces, distributed intelligence and reduced power consumption, Danfoss AC drives optimize the performance of fans.

-

if (isSmallPicture) {

Drives for pumps in commercial buildings

Drives for pumps in commercial buildingsProtect your pump and optimize commercial ventilation and air conditioning performance using AC drives.

Success stories

-

if (isSmallPicture) {

How did this smart factory reach carbon-neutral?

How did this smart factory reach carbon-neutral?POLAND: The new Danfoss production hall in Grodzisk Mazowiecki has reached carbon-neutrality, thanks to full electrification, energy-saving solutions such as Danfoss drives, and energy from renewable sources.

-

if (isSmallPicture) {

How does Beat the Storm deliver more fun for 80% less CO2?

How does Beat the Storm deliver more fun for 80% less CO2?DENMARK: Universe Science Park saves 80% on emissions and the power bill for its wind tunnel attraction “Beat the Storm”, with the intelligent VLT® HVAC drive.

-

if (isSmallPicture) {

Drives secure fresh air inside South America’s tallest building

Drives secure fresh air inside South America’s tallest buildingA huge number of Danfoss drives secure comfortable temperatures and cut down energy use inside Chile’s famous Costanera Center.

-

if (isSmallPicture) {

Danfoss ensures sustainable luxury in the heart of Sønderborg

Danfoss ensures sustainable luxury in the heart of SønderborgDENMARK: Hotel Alsik is proud to be 76% CO2-neutral, with sustainable solutions reflected throughout the entirety of this magnificent hotel – from the energy-efficient solutions in the hotel rooms, the design of the building and the power supply, to the 380 m2 solar cells on the roof.

-

if (isSmallPicture) {

Convention Center Exhibits Major Pump Energy Savings

Convention Center Exhibits Major Pump Energy SavingsDanfoss Drives VFD retrofit project helped the one million square foot Enercare Centre in Toronto, Canada save energy with dramatically improved pump motor efficiency, cut electricity costs, and helped achieve the center's sustainability goals.

-

if (isSmallPicture) {

VACON® 20 X

VACON® 20 XVACON® 20 X has reached the Limited phase of its lifecycle and is no longer in active production. We will help you select the optimal replacement.

-

if (isSmallPicture) {

VLT® Micro Drive FC 51

VLT® Micro Drive FC 51The smallest drives in the FC51 series are ideal for side-by-side mounting with a high integration density.

-

if (isSmallPicture) {

VLT® Refrigeration Drive FC 103

VLT® Refrigeration Drive FC 103FC103 is dedicated to controlling compressors, pumps and fans for significant energy savings in refrigeration plants.

-

if (isSmallPicture) {

VACON® 20

VACON® 20Compact, but packed with programming functionality that’s ideal for OEM applications.

-

if (isSmallPicture) {

VACON® 100 X

VACON® 100 XA drive for indoor and outdoor applications that withstands high pressure and vibration levels, water, heat and dirt.