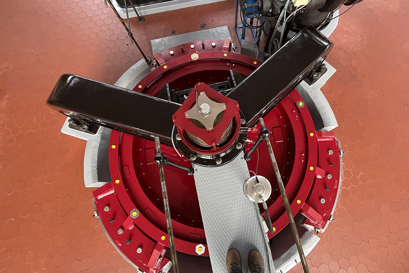

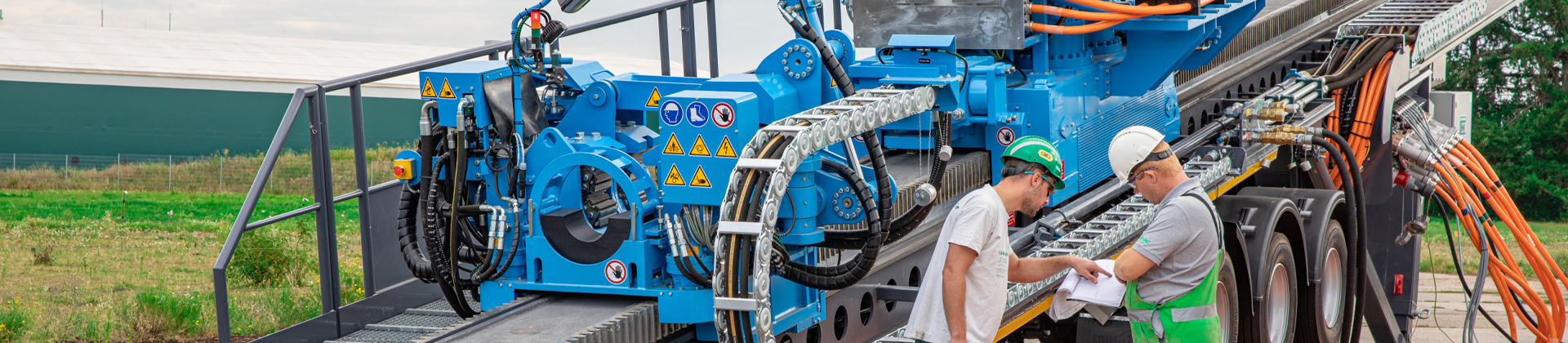

NETHERLANDS: With construction machines accounting for around 1.1% of annual global emissions, all efforts to achieve emission reductions are imperative. In 2022, with support from Danfoss, Herrenknecht was able to commission a new electrified version of their horizontal directional drilling rig. Capable of drilling up to 1,500 meters, the rig demands high torque accuracy while also remaining mobile.

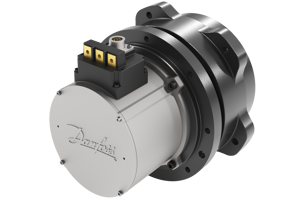

By equipping their HDD rig with Danfoss EDITRON EM-PMI synchronous reluctance assisted permanent magnet motors and iC7-Automation drives, Herrenknecht achieved the necessary power without compromising mobility. The HDD rig is now not only more energy efficient but even delivers better performance than the previous hydraulic system.

Read on to discover how the electrification of Herrenknecht’s HDD rig with EDITRON motors and iC7-Automation drives exceeds expectations.

The challenge: Rig mobility with high performance

Construction sites are under pressure to decarbonize, but hesitation remains due to unproven opportunities in electrification. For this reason, Herrenknecht and Danfoss were determined to measure and demonstrate the benefits of their state-of-the-art technology.

For Herrenknecht’s HDD rig, mobility is an essential feature, imposing constraints on size and power supply. With only a 400V AC power supply available from the grid, successful electrification depended on an efficient AFE system to boost the voltage for high-speed drill operation.

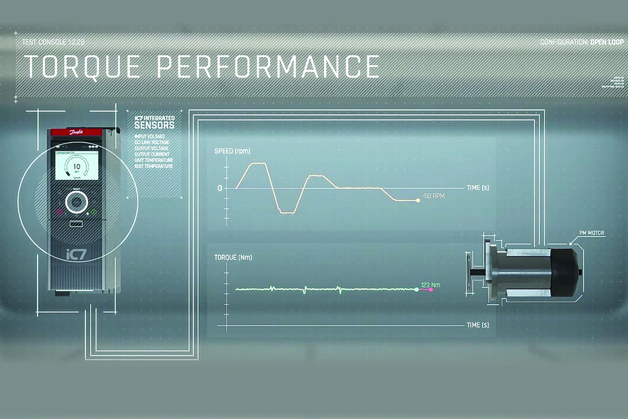

The HDD rig sets particularly high demands on torque accuracy. To protect gears and mechanics, it is crucial that the system can react to the fast torque jerks that can occur when drilling in either soft ground or rock. Additionally, eliminating coasting is critical because after ramp-down, the boring bars will be wound up like a spring. Any coast would cause them to accelerate in the opposite direction, which risks loosening the screw connections of the drill rods. Instead, the drive must slowly reduce the torque after reaching zero speed to gradually relax the tension.

The solution: High precision and unprecedented torque control

In selecting motors for the HDD rig, Herrenknecht faced a choice between traditional induction motors and the more advanced EDITRON EM-PMI SRPM motor. Given the rig's mobility requirements, the compact and lightweight design of the SRPM motors made them the preferred option over the bulkier induction motors. Moreover, the EDITRON motors’ approximately 96% energy rating and precise torque and speed control are crucial for meeting high-performance needs, providing both energy efficiency and operational precision.

Paired with iC7-Automation air-cooled system modules that offer unprecedented torque control, the motors can successfully meet the rigorous demands of the mobile horizontal drilling rig. The AFE effectively harnesses the potential energy of the drill and converts 400 V AC supply into 700 V DC, while also minimizing harmonics, allowing the rig to maximize the use of grid electricity.

To ensure an even distribution of power between the mechanically connected motors, protect the mechanics, and maintain consistent performance, the iC7-Automation drives are equipped with a unique Load Drooping feature. In this installation, the system load-droops six connected PM motors in a high-speed setting range down to zero speed, while maintaining high torque accuracy.

- Superior low-speed performance due to new original control algorithms

- High torque accuracy with 0-370 Hz frequency adjustments

- Load drooping feature provides even power distribution and consistent performance

- Ability to boost DC voltage with AFE system

- Combines high torque and power in a compact design to minimize footprint

- Designed with Safe Torque Off (STO SIL3) as standard for enhanced safety

Learn more

The outcome: Generating 700 V DC from a 400 V AC grid supply

The integration of high-efficiency SRPM motors alongside the AFE technology led to considerable energy savings and allows Herrenknecht to fully utilize the 400 V AC grid supply to generate 700 V DC. And when grid power is unavailable, the AFE optimizes power use enough to permit the use of a smaller diesel generator.

Because the setup also helps minimize harmonics, the size can be further reduced to approximately 370 kVA instead of the typical 440 kVA, thereby using a unit nearly 40-50% smaller than what might otherwise be required.

The result is an advanced electrified mobile horizontal directional drilling rig that is proven in the field. Thanks to electrification, the HDD rig not only reached the necessary performance but also exceeded expectations by outperforming the previous hydraulic system.

Related products

A wide range of electric machines allows to select the exact machine type to fit the required torque, speed or power. Highest efficiency enabling higher operating ranges in hybrid- or full-electric applications. All electric machines are designed for the harsh operating conditions in work machines, commercial vehicles and marine applications.

eDrive consists of high-power, air cooled, 2in1 electric inverter and two interior permanent magnet electric motors integrated with high-performance gearboxes.

A wide range of electric machines allows to select the exact machine type to fit the required torque, speed or power. Highest efficiency enabling higher operating ranges in hybrid- or full-electric applications. All electric machines are designed for the harsh operating conditions in work machines, commercial vehicles and marine applications.

Case studies

AUSTRALIA: In the semi-arid inland climate of the Riverina Region of New South Wales, where irrigation is essential to farming, the operator of Cadell Orchards faced a significant energy challenge. In its off-grid operation spanning 1,690 hectares, the Sunraysia almond orchard sustains more than 500,000 almond trees.